Aerogel composite structure material as well as preparation method and application thereof and structure or device comprising same

A composite structure and airgel technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of poor compression resistance, low heat insulation density, etc., and achieve heat resistance Good, simple process, strong heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Further, the preparation method of the airgel composite structural material of the present invention mainly includes the following steps:

[0049] First, the ungelled, airgel reactant solution is poured into the hollow glass microspheres. The volume of the solution is 90-130% of the hollow glass microspheres, which forms a viscous mixture;

[0050] Then, the reinforcing fiber web is laid flat, the aforementioned mixture is poured into the surface of the reinforcing fiber web, and the addition amount of the mixture is controlled simultaneously, and the height of the mixture is 90 to 110% of the thickness of the reinforcing fiber web ( For example, the grid void volume of the reinforced fiber web can be measured at first, and then the addition amount of the mixture can be determined according to the grid void volume); then, the mixture is scraped off with a scraper, so that the mixture can be evenly distributed on the surface of the reinforced fiber web, and filled Reinfo...

Embodiment 1

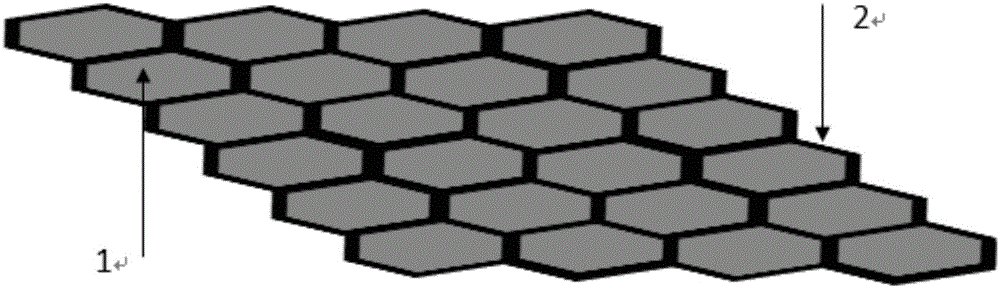

[0055] Such as figure 1 As shown, in this implementation, the hollow glass microspheres are selected from 3M S60HS hollow glass microspheres with a compressive strength of 124.02 MPa and a particle size between about 1 micron and 10 microns; meanwhile, the reinforcing fiber web 2 is a thickness of 2 mm alkali-free glass fiber mesh, the mesh size is 5mm×5mm;

[0056] Then, prepare the airgel composite structure material according to the following method:

[0057] (1) Pour the solution of the ungelled airgel reactant into the hollow glass microspheres, the volume of the solution is 90% to 130% of the hollow glass microspheres, forming a viscous mixture;

[0058] (2) Spread the reinforcing fiber web 2 flat, pour the aforementioned mixture into the surface of the reinforcing fiber web 2, and make the height of the mixture the same as the thickness of the reinforcing fiber web; then, scrape the mixture with a scraper, so that the mixture can be The surface of the reinforcing fibe...

Embodiment 2

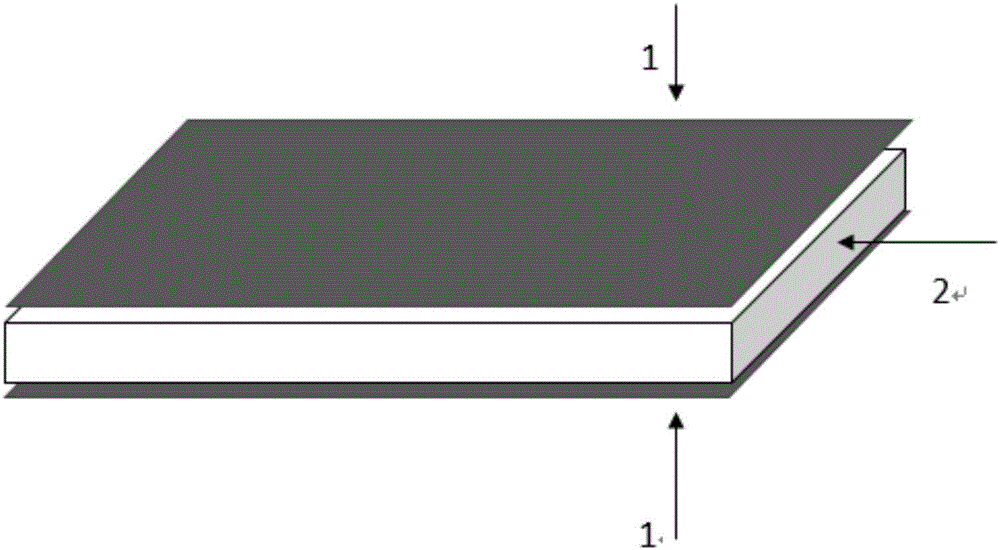

[0063] figure 2 It is a high compressive, high tensile airgel composite structural material, on the basis of the material structure of Example 1, carbon fiber cloth 1 is pasted with epoxy resin on the upper and lower surfaces, and a product with high tensile strength is obtained ;

[0064] Specifically, in this embodiment, the hollow glass microspheres are 3M S60HS hollow glass microspheres, the compressive strength of which is 124.02MPa, and the particle size is between 1 micron and 10 microns; at the same time, the reinforced fiber net is 2 microns thick. mm alkali-free glass fiber mesh, the grid size is 5mm × 5mm; the veneer layer is a carbon fiber cloth layer;

[0065] Then, prepare the airgel composite structure material according to the following method:

[0066] (1) Pour the solution of the ungelled airgel reactant into the hollow glass microspheres, the volume of the solution is 90% to 130% of the hollow glass microspheres, forming a viscous mixture;

[0067] (2) S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com