Chromium pollution soil restoration agent, and preparation method and application thereof

A technology of chromium-contaminated soil and remediation agent, applied in the field of pollution treatment, can solve the problems of loss of nutrient elements, damage to soil structure, and high treatment costs, and achieve the effects of remediating soil fertility, improving ecological environment, and improving polluted soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

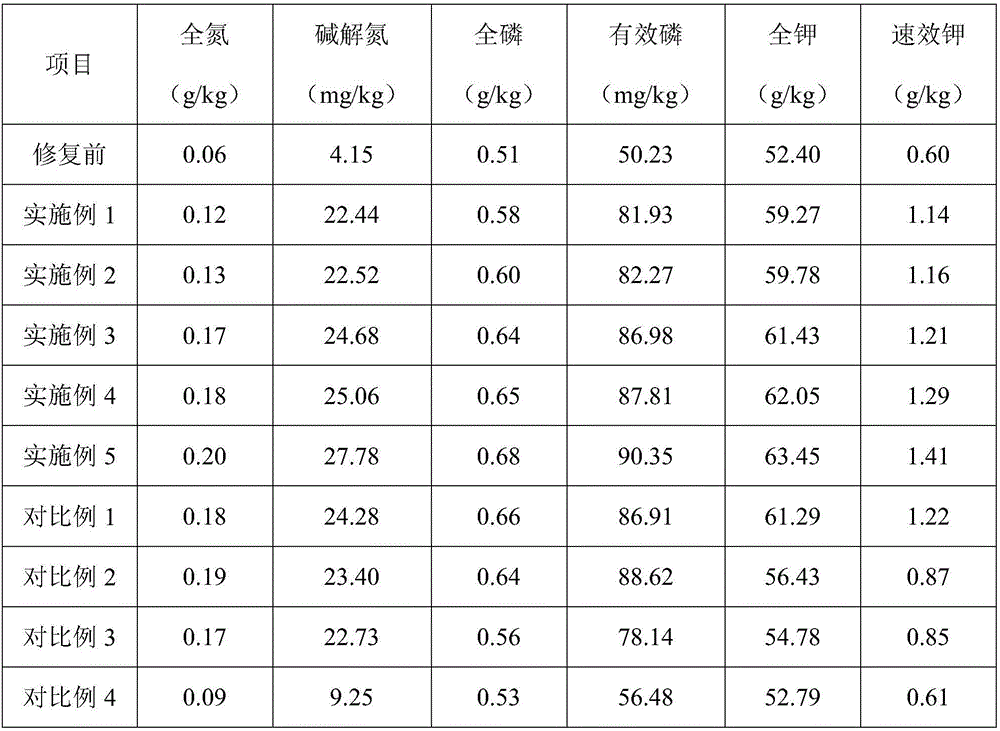

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a chromium-contaminated soil remediation agent is made of the following raw materials in terms of parts by mass: 88 parts of camphor wood, 23 parts of Yuyu grain, 14 parts of calcium silicate, 18 parts of potassium phosphate, nitrophosphoric acid Ammonium 27 parts.

[0021] The preparation method of described chromium-contaminated soil remediation agent comprises the following steps:

[0022] (1) Camphorwood and Yuyuliang are crushed into powder respectively, passed through a 200-mesh sieve, and dried to obtain camphorwood powder and Yuyuliang powder for subsequent use;

[0023] (2) Mix camphor wood powder and Yuyu grain powder in proportion, place them in a nitric acid solution with a mass concentration of 3.8 times the sum of their masses and soak for 1 hour in a 16% nitric acid solution, filter to obtain mixture A;

[0024] (3) Mix mixture A and calcium silicate uniformly in proportion, then transfer it into a non-metallic...

Embodiment 2

[0027] In the embodiment of the present invention, a chromium-contaminated soil remediation agent is made of the following raw materials in terms of parts by mass: 100 parts of camphor wood, 28 parts of Yuyu grain, 19 parts of calcium silicate, 24 parts of potassium phosphate, nitrophosphoric acid Ammonium 36 parts.

[0028] The preparation method of described chromium-contaminated soil remediation agent comprises the following steps:

[0029] (1) Camphorwood and Yuyuliang are crushed into powder respectively, passed through a 250-mesh sieve, and dried to obtain camphorwood powder and Yuyuliang powder for subsequent use;

[0030] (2) Mix camphor wood powder and Yuyu grain powder in proportion, place them in a nitric acid solution with a mass concentration of 4.4 times the sum of their masses, soak for 2 hours, and filter to obtain mixture A;

[0031] (3) Mix mixture A and calcium silicate uniformly in proportion, then transfer it into a non-metallic container, place it in a m...

Embodiment 3

[0034] In the embodiment of the present invention, a chromium-contaminated soil remediation agent is made of the following raw materials in terms of parts by mass: 92 parts of camphor wood, 24 parts of Yuyu grain, 15 parts of calcium silicate, 20 parts of potassium phosphate, nitrophosphoric acid Ammonium 30 parts.

[0035] The preparation method of described chromium-contaminated soil remediation agent comprises the following steps:

[0036] (1) Camphorwood and Yuyuliang are crushed into powder respectively, passed through a 200-mesh sieve, and dried to obtain camphorwood powder and Yuyuliang powder for subsequent use;

[0037] (2) Mix the camphor wood powder and Yuyu grain powder in proportion, place them in a nitric acid solution with a mass concentration of 3.8 times the sum of their masses and soak for 2 hours in a nitric acid solution of 16%, and filter to obtain mixture A;

[0038] (3) Mix mixture A and calcium silicate uniformly in proportion, then transfer it into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com