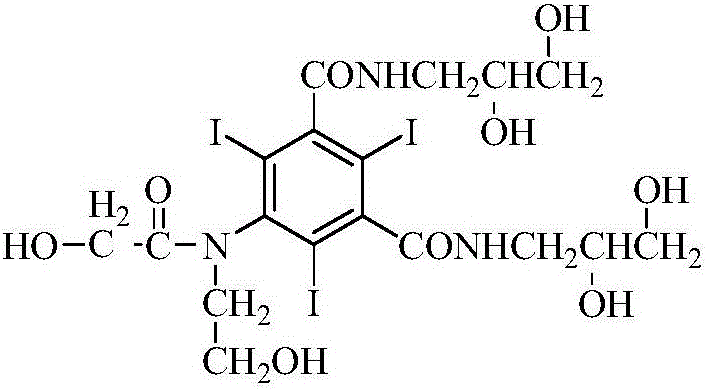

Preparation method for ioversol

A technology of ioversol and alkylation reaction, which is applied in the field of ioversol preparation and can solve problems such as difficulty in removing and increasing the number of refining times of ioversol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

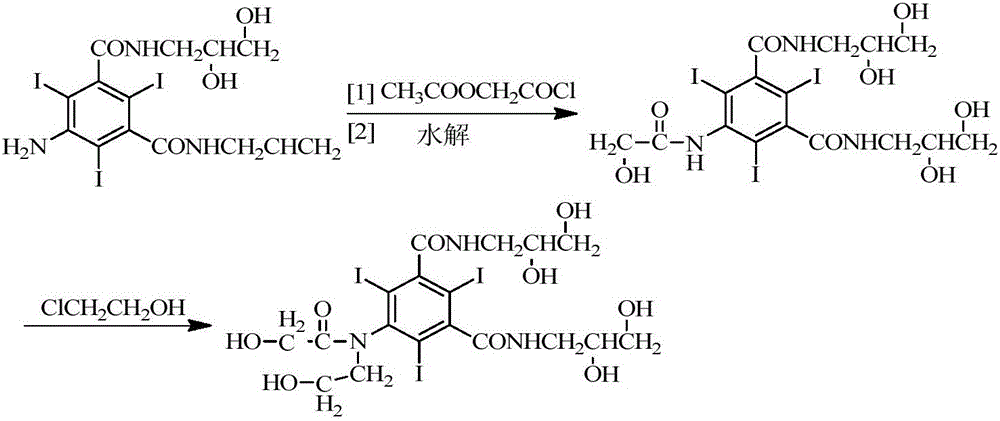

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the synthesis of ioversol (water used is purified water, iron content is 0.05ppm or lower)

[0041] In a three-necked flask equipped with a stirrer and a reflux condenser, add 50g (0.06mol) of 5-chloroacetamido-N,N'-bis-(2,3-dihydroxypropyl)-2,4,6- Triiodo-1,3-phthalamide, sodium hydroxide (4.8g, purified water 100ml, pH=12.5), tetrahydrofuran 30ml, stir to dissolve, add 14.5g (0.18mol) chloroethanol, heat up to 50°C, stir Reaction 11.5h. Use 5mol / L hydrochloric acid solution to adjust the pH of the reaction solution to 6.0, add 26g (0.317mol) of anhydrous sodium acetate, add concentrated hydrochloric acid or sodium hydroxide solution dropwise under stirring to adjust the pH to 6.5, and heat to reflux for 13h. The purity of HPLC was 93.12%, and the impurity I was 2.95% (direct sampling for detection).

[0042]Concentrate under reduced pressure, add methanol to the residue, filter, concentrate the filtrate to remove methanol, add 100ml of water, add 2g of...

Embodiment 2

[0043] Embodiment 2: the synthesis of ioversol (water used is industrial water, iron content is 500ppm)

[0044] In a three-necked flask equipped with a stirrer and a reflux condenser, add 20g (0.024mol) of 5-chloroacetamido-N,N'-bis-(2,3-dihydroxypropyl)-2,4,6- Triiodo-1,3-phthalamide, sodium hydroxide (1.92g, industrial water 40ml, pH=12.5), tetrahydrofuran 30ml, stir to dissolve, add 5.8g (0.072mol) chloroethanol, heat up to 50°C, stir Reaction 11h. Use 5 mol / L hydrochloric acid solution to adjust the pH of the reaction solution to 6.0, add 10.4 g of anhydrous sodium acetate, add concentrated hydrochloric acid or sodium hydroxide solution dropwise under stirring to adjust the pH to 6.5, and heat to reflux for 12 hours. The purity detected by HPLC was 87.21%, and the impurity I was 9.72% (directly sampled for detection).

[0045] Concentrate under reduced pressure, add methanol to the residue, filter, concentrate the filtrate to remove methanol, add 40ml of water, add 0.8g...

Embodiment 3

[0046] Embodiment 3: the synthesis of ioversol (water used is purified water, adds 0.4g iron trichloride)

[0047] In a three-necked flask equipped with a stirrer and a reflux condenser, add 20g (0.024mol) of 5-chloroacetamido-N,N'-bis-(2,3-dihydroxypropyl)-2,4,6- Triiodo-1,3-phthalamide, sodium hydroxide (1.92g, purified water 40ml, pH=12.5), tetrahydrofuran 30ml, stir to dissolve, add 5.8g (0.072mol) chloroethanol, heat up to 50°C, stir Reaction 11h. Use 5mol / L hydrochloric acid solution to adjust the pH of the reaction solution to 6.0, add 10.4g of anhydrous sodium acetate and 0.4g of ferric chloride, add concentrated hydrochloric acid or sodium hydroxide solution dropwise under stirring to adjust the pH to 6.5, and heat to reflux for 12h. The purity detected by HPLC was 83.21%, and the impurity I was 12.67% (directly sampled for detection).

[0048] Exploration of process conditions - screening reaction conditions

[0049] With reference to the method for preparing iove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com