Method for separating acetonitrile-methanol-benzene three-element azeotrope by heat-integration tri-tower variable-voltage rectification

A technology of benzene ternary azeotrope and pressure swing rectification, which is applied in distillation purification/separation, chemical instruments and methods, hydrocarbon purification/separation, etc., to improve product purity, reduce rectification processing capacity, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

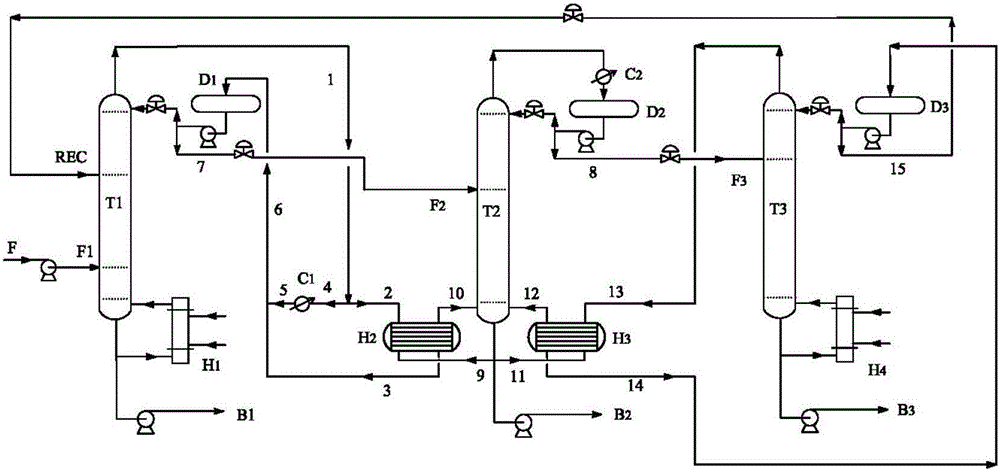

Method used

Image

Examples

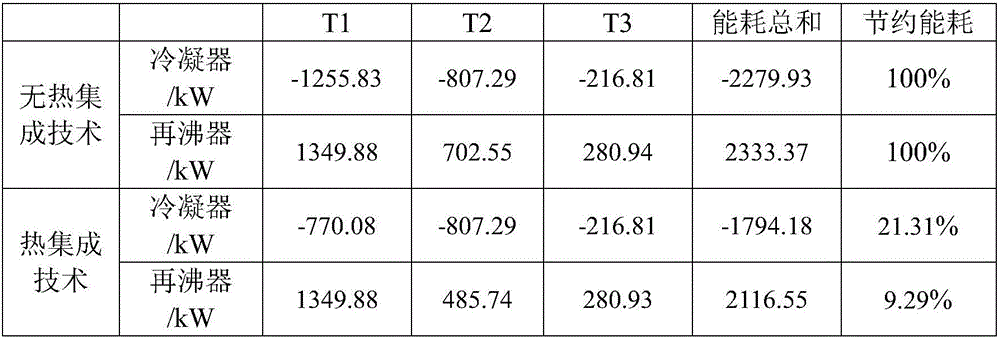

Embodiment 1

[0041] Feed flow rate 1000kg / h, temperature 25°C, mass composition: 20% acetonitrile, 70% methanol, 10% benzene. The number of effective theoretical plates of column T1 is 48, the raw material liquid is introduced from the 39th plate, the circulating feeding position is the 16th plate, the operating pressure is 6atm, the reflux ratio is 2.38, and the tower diameter is about 710mm; the effective theoretical plate of column T2 The total number is 54. The production liquid at the top of tower T1 is introduced from the 14th plate. The operating pressure is 1 atm, the reflux ratio is 2.57, and the tower diameter is about 670mm. The outlet liquid is introduced by the third plate, the operating pressure is 6atm, the reflux ratio is 0.2, and the tower diameter is about 370mm. After separation and treatment, the product purity of acetonitrile was 0.9995, the product purity of methanol was 0.9995, and the product purity of benzene was 0.9995. The recovery rate of acetonitrile was 99.80%...

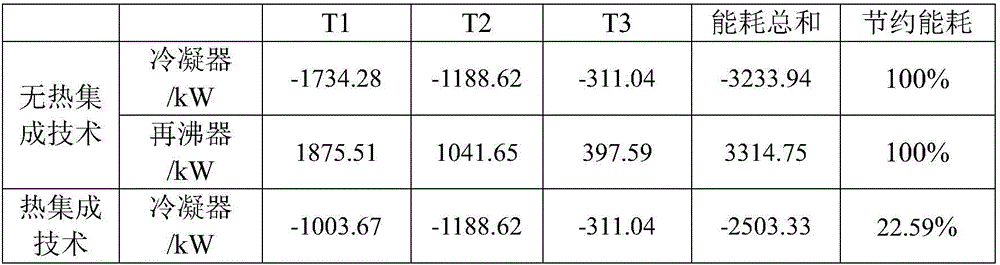

Embodiment 2

[0046] Feed flow rate 1500kg / h, temperature 25°C, mass composition: 20% acetonitrile, 70% methanol, 10% benzene. The number of effective theoretical plates of column T1 is 54, the raw material liquid is introduced from the 39th plate, the circulating feed position is the 25th plate, the operating pressure is 6atm, the reflux ratio is 2.30, and the column diameter is about 820mm; the effective theoretical plate of column T2 The total number is 57. The production liquid at the top of tower T1 is introduced from the 15th plate. The operating pressure is 1 atm, the reflux ratio is 2.94, and the tower diameter is about 820 mm. The effective theoretical plate number of tower T3 is 15. The outlet liquid is introduced by the fourth plate, the operating pressure is 6atm, the reflux ratio is 0.3, and the tower diameter is about 440mm. After separation and treatment, the product purity of acetonitrile was 0.9995, the product purity of methanol was 0.9995, and the product purity of benzen...

Embodiment 3

[0052] Feed flow rate 500kg / h, temperature 30°C, mass composition: 20% acetonitrile, 70% methanol, 10% benzene. The number of effective theoretical plates in column T1 is 46, the raw material liquid is introduced from the 36th plate, the circulating feeding position is the 18th plate, the operating pressure is 6atm, the reflux ratio is 1.2, and the column diameter is about 470mm; the effective theoretical plate of column T2 is The total number is 50. The production fluid at the top of tower T1 is introduced from the 16th plate. The operating pressure is 1 atm, the reflux ratio is 1.95, and the tower diameter is about 490 mm. The outlet liquid is introduced by the fourth plate, the operating pressure is 6atm, the reflux ratio is 0.18, and the tower diameter is about 200mm. After separation and treatment, the product purity of acetonitrile was 0.9995, the product purity of methanol was 0.9995, and the product purity of benzene was 0.9995. The recovery rate of acetonitrile was 99...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com