Synthesis method of flame-retarding polymethyl methacrylate

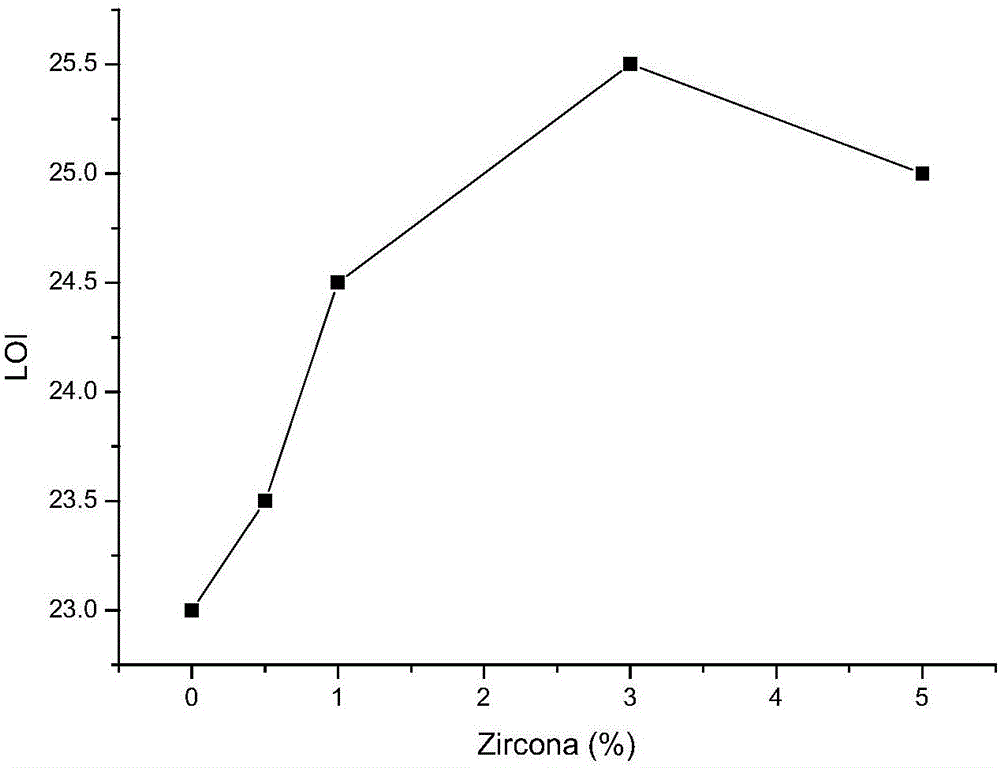

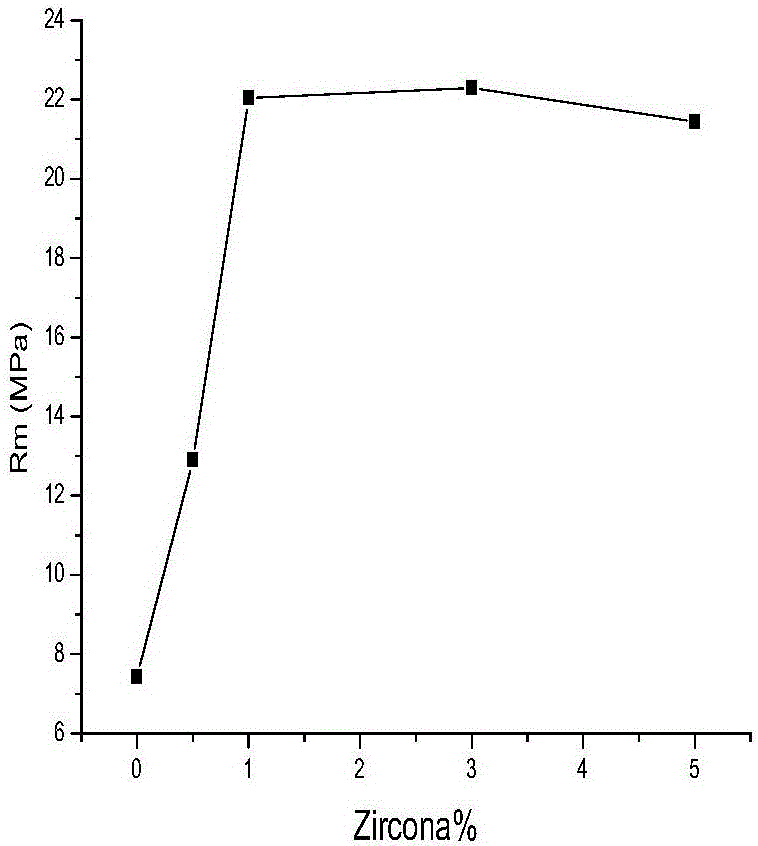

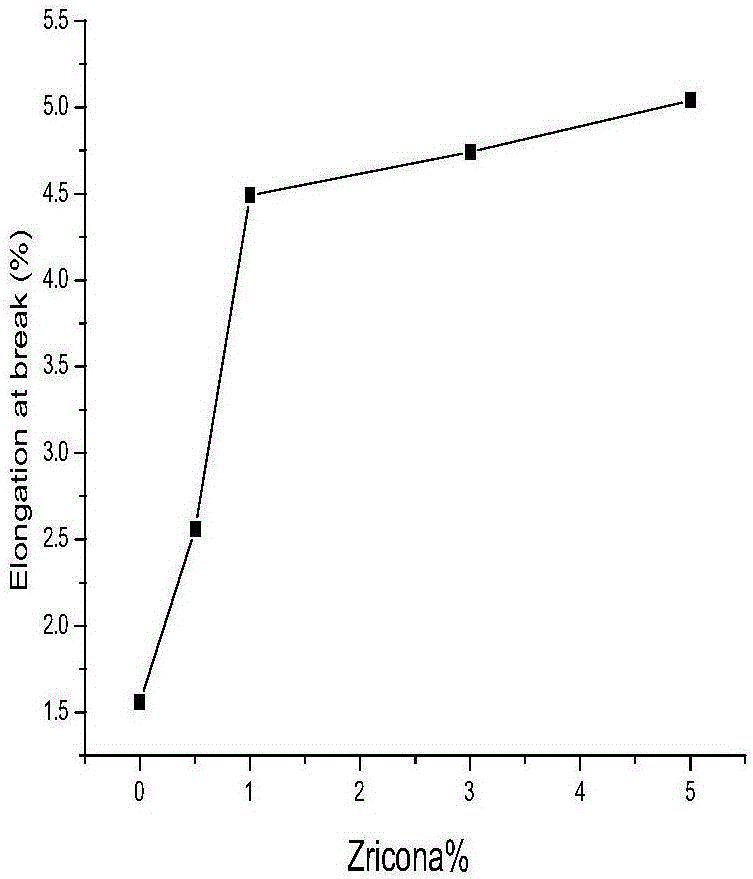

A technology of polymethyl methacrylate and methyl methacrylate, applied in the field of flame retardant materials, can solve the problems of poor heat resistance, life-threatening safety and property safety, hidden dangers of large fires, etc., and achieve excellent mechanical properties and heat release. The effect of low rate and low mass loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] like Figure 1 to Figure 9 As shown, this scheme includes the following steps in sequence:

[0021] (1) Recrystallization is carried out to dibenzoyl peroxide at room temperature: 6g of dibenzoyl peroxide to be purified is melted in 24ml of trichloromethane, impurities are filtered out, and an equal volume of methanol is added to treat dibenzoyl peroxide The benzoyl crystals were separated out, filtered, and the crystals were washed with cold methanol, dried in a vacuum drying oven at room temperature, and stored in the dark for future use;

[0022] (2) Preparation of samples: in methyl methacrylate at room temperature, add triphenyl phosphate, nano-zirconium dioxide, N,N-dimethylaniline, and recrystallized diphenyl peroxide to the container in turn according to the recipe. Benzoyl is mixed, wherein methyl methacrylate is 19.35g, triphenyl phosphate is 4.59g, nano zirconium dioxide is 0.24g, N,N-dimethylaniline is 0.09g, dibenzoyl peroxide is 0.56g, then seal the mout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com