Lignin-based aldehyde-free adhesive and preparation and application method thereof

A technology of lignin-based, aldehyde adhesives, applied in the field of adhesives, can solve problems such as threats to human health, and achieve the effect of solving formaldehyde release, excellent dry strength and wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a lignin-based formaldehyde-free adhesive, comprising the following steps:

[0022] 1) mixing lignin and / or its derivatives, catalyst and water to obtain a reduction system;

[0023] 2) adjusting the pH value of the reduction system to 10-11, and then performing activation treatment, and the obtained activation treatment product includes the upper layer mixed solution and the lower layer precipitate;

[0024] 3) heat-treating the lower precipitate, protein-rich substance and water to obtain a lignin-based formaldehyde-free adhesive.

[0025] In the present invention, lignin and / or its derivatives, catalyst and water are mixed to obtain a reducing system. In the present invention, there is no special requirement on the method of mixing to obtain the reducing system, and the method of mixing materials well known to those skilled in the art can be used for mixing. In the present invention, the mixing is preferably carried out...

Embodiment 1

[0038] The reduction system comprising 100 parts of cellulose ethanol lignin, 0.5 parts of catalyst and 400 parts of water was treated at a stirring rate of 300 rpm and 30 °C for 6 hours; then 3% sodium hydroxide solution was added to adjust the pH value to 10, at 65 Activation at °C for 1 hour.

[0039] The activated product was centrifuged at a rate of 3500rpm to obtain a lower layer of sediment; a mixture of 100 parts of the lower layer of sediment, 20 parts of soybean flour and 150 parts of water was heated at a stirring rate of 370 rpm and 35°C for 1 hour to obtain a lignin-based Formaldehyde-free adhesive.

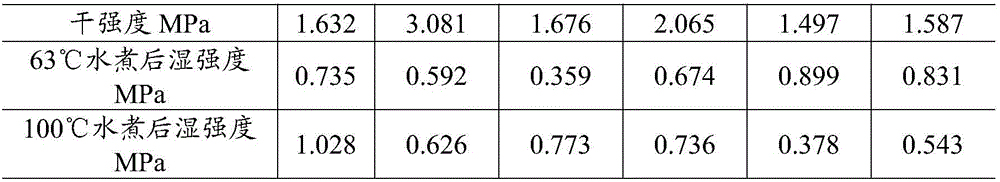

[0040] The present invention also detects the bonding properties of the adhesive obtained in this embodiment, and the detection results are shown in Table 1.

[0041] The bonding strength of the adhesive that the present embodiment of table 1 obtains

[0042]

[0043] It can be seen from Table 1 that the adhesive obtained in this example has excellent dry streng...

Embodiment 2

[0045] Treat the reducing system containing 100 parts of hydrolyzed lignin, 1.5 parts of catalyst and 600 parts of water at a stirring rate of 270rpm at 40°C for 9 hours; then add 5% potassium hydroxide solution to adjust the pH value to 11, at 75°C Activate for 2 hours.

[0046] The activated product was centrifuged at a rate of 3500rpm to obtain a lower sediment; a mixture of 100 parts of the lower sediment, 40 parts of soybean flour and 400 parts of water was heated at 45°C for 0.5 hours at a stirring rate of 370 rpm to obtain a lignin-based Formaldehyde-free adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com