Preparation and differentiation methods of micro-nano topological structure for promoting mesenchymal stem cell differentiation

A topological structure and qualitative stem cell technology, applied in the field of micro-nano biomaterials and its application, can solve the problems of poor induction and differentiation effect, cumbersome operation process, large time consumption and workload, etc., to enhance the induction ability of osteotropic differentiation, The effect of firm binding and high proliferation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

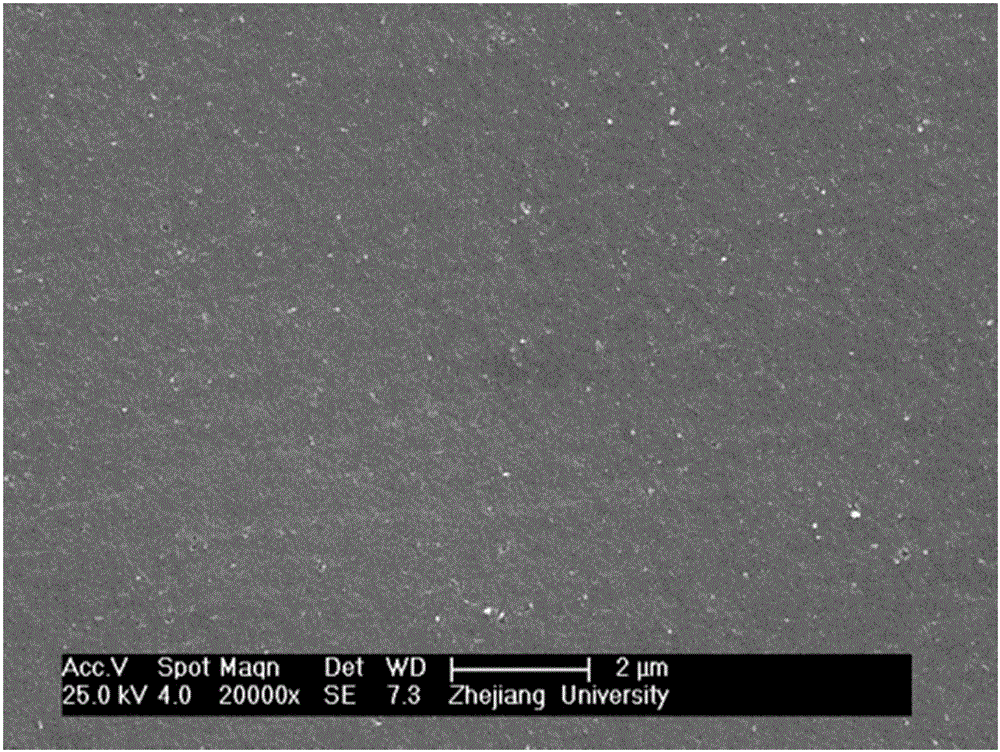

[0041] (1) Prepare a water-soluble silk protein solution, adjust the concentration of the silk protein solution to 1 mg / mL, and perform ultrasonic treatment for 10 min.

[0042] (2) CaCl 2 The particles were added to 100 mL of silk protein solution in step (1) for premineralization for 1 h, and the CaCl 2 completely dissolved, making the CaCl 2 The final concentration was 20mM.

[0043] (3) 100 mL of Na with a molar concentration of 12 mM 2 HPO 4The solution was slowly dripped into the solution in step (2) through a constant flow pump device for mineralization, the dropping rate was controlled at 10mL / min, and a magnetic stirrer was used to stir during the period. The mineralization temperature was controlled between 4° C., and the pH of the system was kept constant at 9.5 by dropping the solution of 0.1 M NaOH.

[0044] After the dropwise addition, the stirring was continued at a relatively fast speed for 2 hours, so that the apatite crystals were layered on the fibroin ...

Embodiment 2

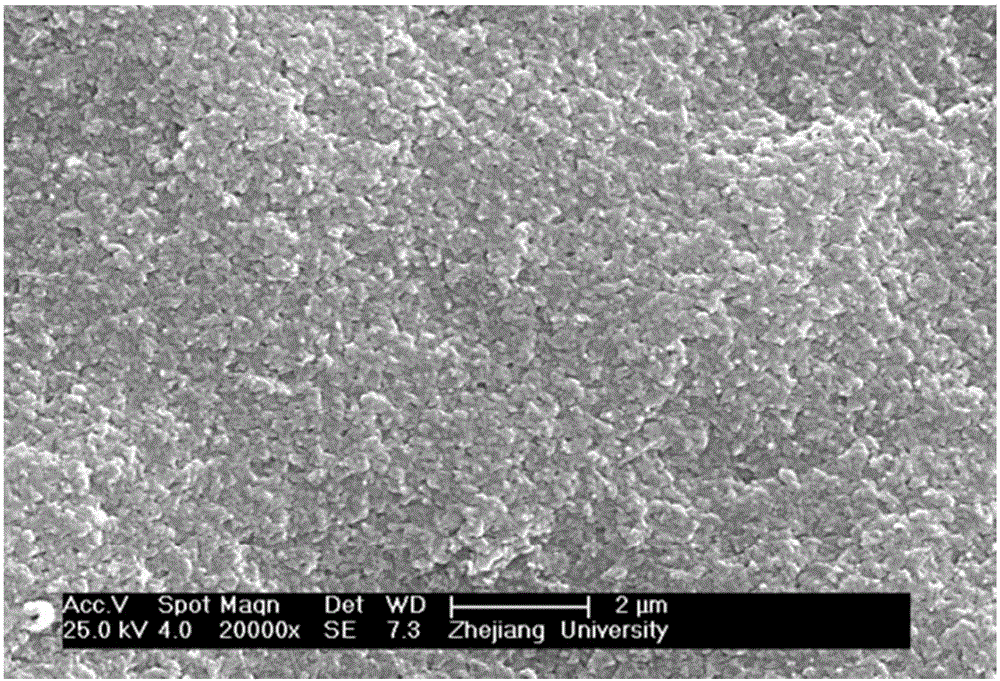

[0051] (1) Prepare a water-soluble silk protein solution, adjust the silk protein solution to 1 mg / mL, and perform ultrasonic treatment for 10 min.

[0052] (2) CaCl 2 The particles were added to 100 mL of silk protein solution in step (1) for premineralization for 1 h, and the CaCl 2 completely dissolved, making the CaCl 2 The final concentration was 20 mM.

[0053] (3) 100 mL of Na with a molar concentration of 12 mM 2 HPO 4 The solution was slowly dripped into the solution in step (2) through a constant flow pump device for mineralization, the dropping rate was controlled at 10mL / min, and a magnetic stirrer was used to stir during the period. The mineralization temperature was controlled between 40° C., and the pH of the system was kept constant at 9.5 by dropping the solution of 0.1 M NaOH. Continue to stir at a faster speed for 24 hours after the dropwise addition, so that the apatite crystals are laminated on the AS template.

[0054] (4) Take out the solution in s...

Embodiment 3

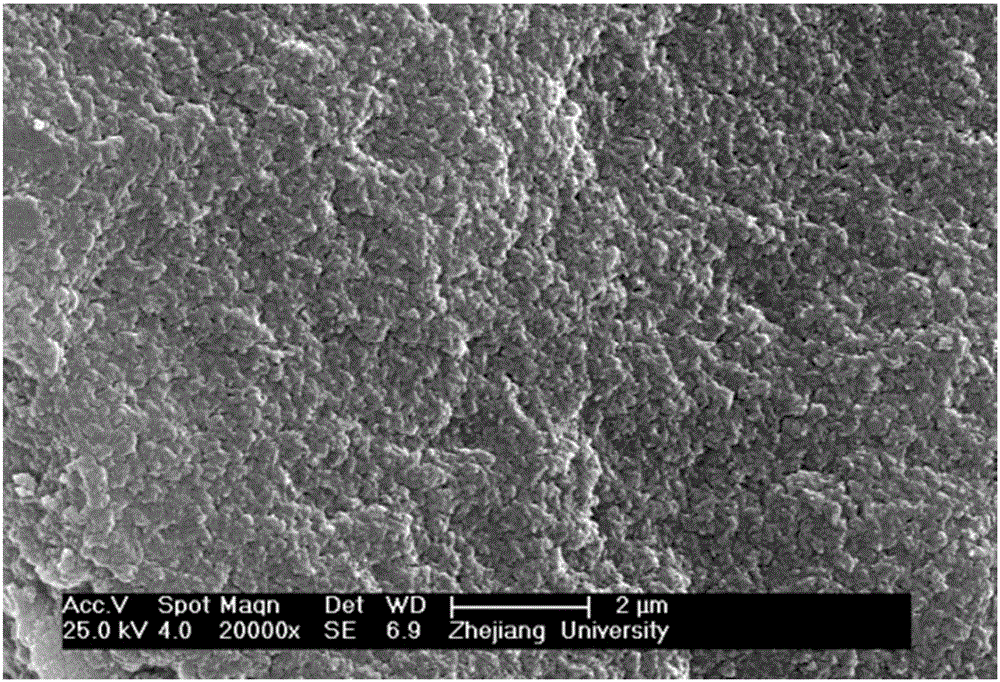

[0060] (1) Prepare a water-soluble silk protein solution, adjust the silk protein solution to 1 mg / mL, and perform ultrasonic treatment for 10 min.

[0061] (2) CaCl 2 The particles were added to 100 mL of silk protein solution in step (1) for premineralization for 1 h, and the CaCl 2 completely dissolved, making the CaCl 2 The final concentration was 20 mM.

[0062] (3) 100 mL of Na with a molar concentration of 12 mM 2 HPO 4 The solution was slowly dripped into the solution in step (2) through a constant flow pump device for mineralization, the dropping rate was controlled at 10mL / min, and a magnetic stirrer was used to stir during the period. The mineralization temperature was controlled between 40° C., and the pH of the system was kept constant at 9.5 by dropping the solution of 0.1 M NaOH. After the dropwise addition, the stirring was continued at a relatively fast speed for 24 hours, so that the apatite crystals were laminated on the fibroin template.

[0063] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com