Added nano-reinforcement agent for improving mechanical properties of steel and its preparation and use method

A technology of strengthening agent and nano-oxide, applied in the field of iron and steel metallurgy, can solve the problems of smelting accidents, oxygen absorption of molten steel, and unsolved pollution, and achieve the effects of improving mechanical properties, preventing reduction, and eliminating surface effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

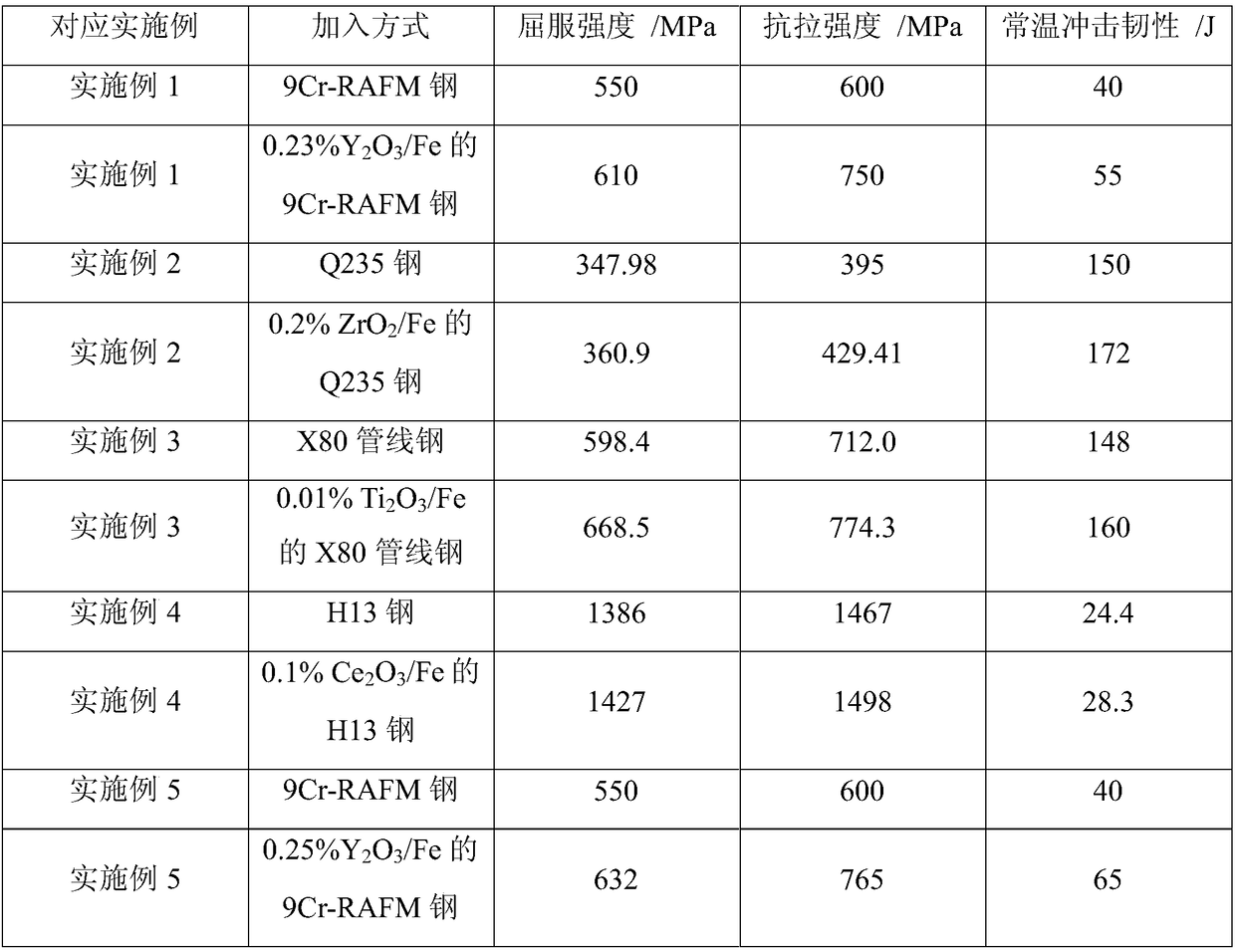

Embodiment 1

[0047] An external nano-reinforcing agent for improving the mechanical properties of steel, which contains nano-oxide particles and Fe, with a mass ratio of, nano-oxide particles: Fe=1:1; wherein, the nano-oxide particles are Y 2 o 3 .

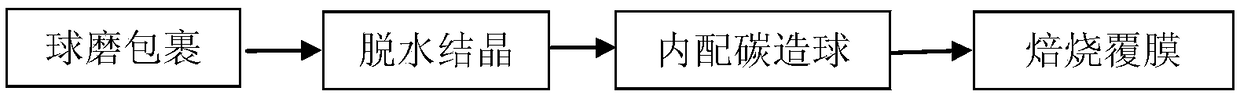

[0048] A method for preparing an external nano-reinforcer for improving the mechanical properties of steel, comprising the following steps:

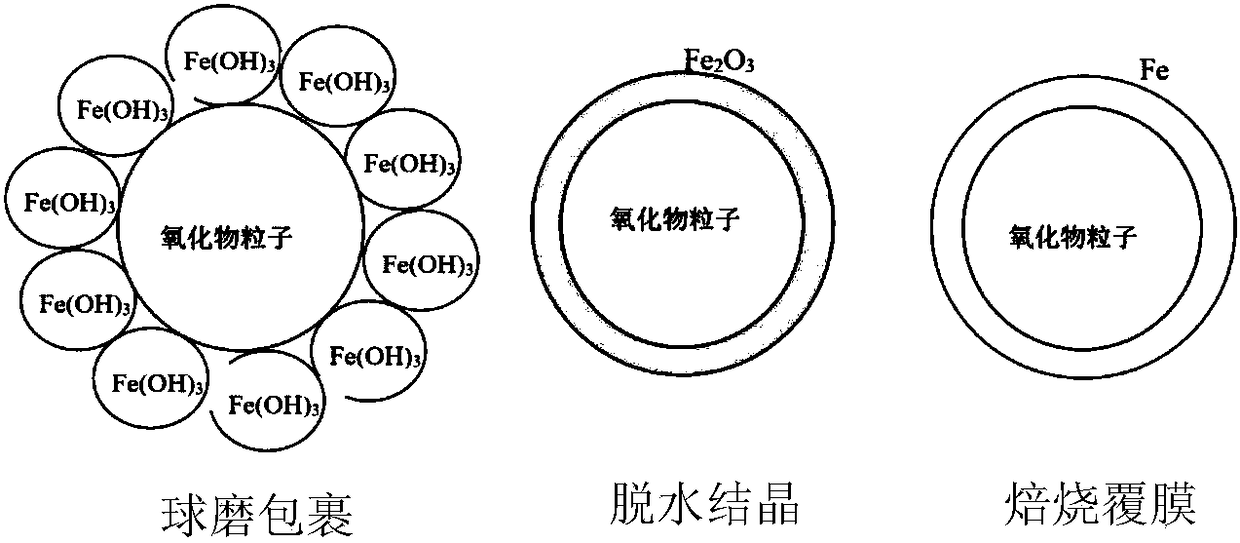

[0049] Step 1, ball mill coating

[0050] Nano oxide particles Y 2 o 3 , Nano Fe(OH) 3 and dispersant acetone are placed in a planetary ball mill for alloying to obtain a ball mill alloyed mixed material;

[0051] Among them, according to the mass ratio, the nano oxide particles Y 2 o 3 : Nano Fe(OH) 3 : acetone=1:2:0.15; nano oxide particles Y 2 o 3 The particle size is 60~90nm; Nano Fe(OH) 3 The particle size is 10-20nm;

[0052] The ball milling process parameters are: the ball milling mode adopts the intermittent type of ball milling 2h shutdown 0.5h; the rotating speed of the ball mill i...

Embodiment 2

[0067] An external nano-reinforcing agent for improving the mechanical properties of steel, which contains nano-oxide particles and Fe, and the mass ratio is, nano-oxide particles: Fe=1:1.5; wherein, the nano-oxide particles are ZrO 2 .

[0068] A method for preparing an external nano-reinforcer for improving the mechanical properties of steel, comprising the following steps:

[0069] Step 1, ball mill coating

[0070] Nano oxide particles ZrO 2 , Nano Fe(OH) 3 and dispersant acetone are placed in a planetary ball mill for alloying to obtain a ball mill alloyed mixed material;

[0071] Among them, according to the mass ratio, the nano-oxide particles ZrO 2 : Nano Fe(OH) 3 : Methanol, ethanol, acetone = 1:3:0.1; Nano oxide particles ZrO 2 The particle size is 50-70nm; nano-Fe(OH) 3 The particle size is 10-30nm;

[0072] The ball milling process parameters are: the ball milling mode adopts the intermittent type of ball milling 2h shutdown 0.5h; the rotating speed of the ...

Embodiment 3

[0087] An external nano-reinforcing agent for improving the mechanical properties of steel, which contains nano-oxide particles and Fe, with a mass ratio of nano-oxide particles: Fe=1:0.8; wherein, the nano-oxide particles are Ti 2 o 3 .

[0088] A method for preparing an external nano-reinforcer for improving the mechanical properties of steel, comprising the following steps:

[0089] Step 1, ball mill coating

[0090] Ti nanoparticles 2 o 3 , Nano Fe(OH) 3 and dispersant acetone are placed in a planetary ball mill for alloying to obtain a ball mill alloyed mixed material;

[0091] Among them, according to the mass ratio, nano-oxide particles Ti 2 o 3 : Nano Fe(OH) 3 : acetone = 1: 1.5: 0.12; nano oxide particles Ti 2 o 3 The particle size is 50-80nm; nano-Fe(OH) 3 The particle size is 10-30nm;

[0092] The ball milling process parameters are: the ball milling mode adopts the intermittent type of ball milling 2h shutdown 0.5h; the rotating speed of the ball mill i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com