Preparation method for high-strength weather-resistant steel for 800Mpa power transmission tower

A technology for transmission towers and weathering steels, which is applied in the field of preparation of high-strength weathering steels for 800Mpa transmission towers, can solve the problems of complex preparation process of hot-dip galvanized layer, high cost of anti-corrosion maintenance, serious environmental pollution, etc., and achieve simple and feasible hot rolling process , the preparation process and the required equipment are simple, and the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

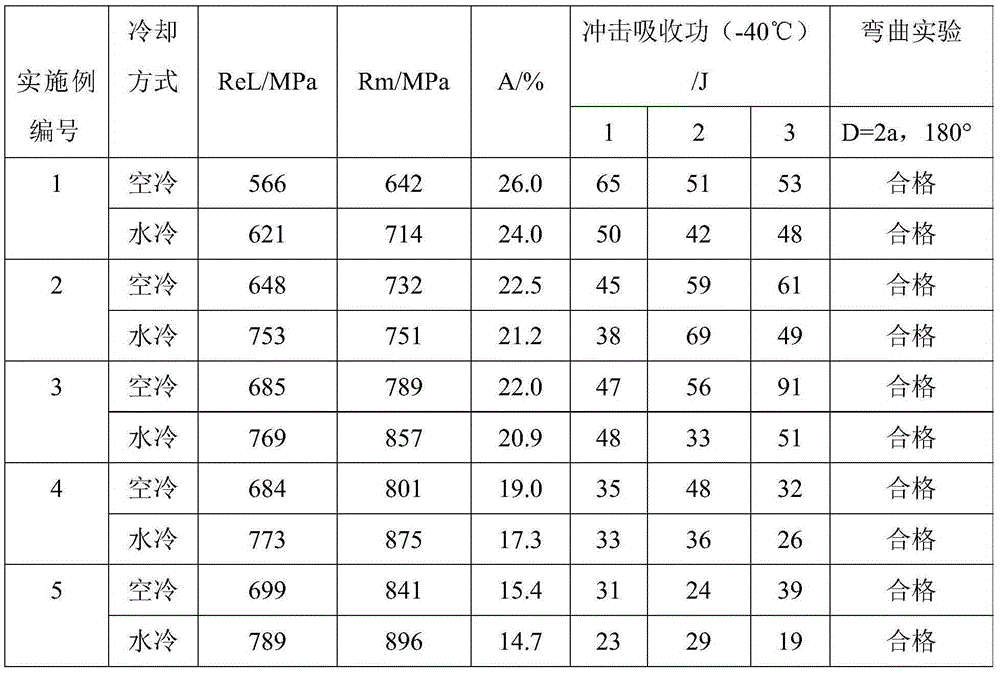

Embodiment 1

[0031] The weathering steel of the present invention is prepared from the following components by weight percentage: C, 0.14%; Si, 1.9%; Mn, 1.2%; P, 0.011%; S, 0.003%; Al, 0.5%; N, 0.0032 %; O, 0.002%; the balance is Fe and trace impurities.

[0032] The weathering steel preparation process steps are as follows:

[0033] 1) Converter or electric furnace smelting; 2) LF refining; 3) Continuous casting; 4) High-temperature heating furnace heating: the billet is heated to 1320°C, the holding time is controlled according to the effective thickness of weathering steel 2.0min / mm, and the initial slab thickness is 80mm, the holding time is 160min; 5) Rough rolling: the thickness of the weathering steel intermediate billet is 10 times the thickness of the finished product (33mm); 6) High temperature finishing rolling: the thickness of the weathering steel intermediate billet is 10 times the thickness of the finished product (33mm), among which, Finish rolling entrance temperature 98...

Embodiment 2

[0035] The weathering steel of the present invention is prepared from the following components by weight percentage: C, 0.17%; Si, 1.0%; Mn, 1.3%; P, 0.012%; S, 0.002%; Al, 0.7%; N, 0.0040 %; O, 0.002%; the balance is Fe and trace impurities.

[0036] The weathering steel preparation process steps are as follows:

[0037]1) Converter or electric furnace smelting; 2) LF refining; 3) Continuous casting; 4) High-temperature heating furnace heating: heat the billet to 1330°C, the holding time is controlled according to the effective thickness of weathering steel 2.0min / mm, and the initial slab thickness is 80mm, the holding time is 160min; 5) Rough rolling: the thickness of the weathering steel intermediate billet is 11 times the thickness of the finished product (32mm); 6) High temperature finish rolling: the thickness of the weathering steel intermediate billet is 11 times the thickness of the finished product (32mm), among which, Finish rolling entrance temperature 980℃, finis...

Embodiment 3

[0039] The weathering steel of the present invention is prepared from the following components by weight percentage: C, 0.18%; Si, 1.1%; Mn, 1.4%; P, 0.013%; S, 0.003%; Al, 0.9%; N, 0.0028 %; O, 0.001%; the balance is Fe and trace impurities.

[0040] The weathering steel preparation process steps are as follows:

[0041] 1) Converter or electric furnace smelting; 2) RH vacuum treatment; 3) Continuous casting; 4) High-temperature heating furnace heating: heating the billet to 1340°C, the holding time is controlled according to the effective thickness of weathering steel 2.0min / mm, the initial slab thickness 5) Rough rolling: the thickness of the weathering steel intermediate billet is 10 times the thickness of the finished product (35mm); 6) High temperature finish rolling: the thickness of the weathering steel intermediate billet is 10 times the thickness of the finished product (35mm), of which , the finish rolling entrance temperature is 1000°C, the final rolling tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com