High-damp-heat-resistant marine atmosphere high-strength weathering resistant steel

A marine atmosphere, high-strength technology, applied in the field of weathering steel, can solve problems such as peeling off of corrosion products, thinning of steel surface, and inability to form a stable rust layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

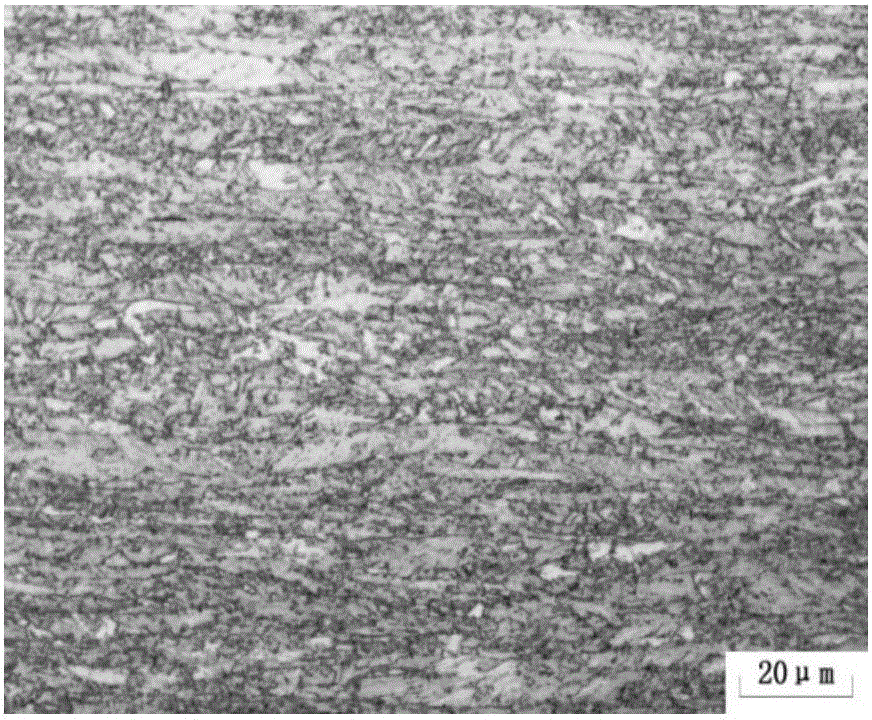

Image

Examples

Embodiment 1

[0036] Example 1 Effects of different Ni contents on the high humidity and heat marine atmospheric corrosion resistance of weathering steel

[0037] Ni is one of the most effective corrosion-resistant elements, but due to the high cost of Ni, it is of great significance to select an appropriate Ni content to obtain weathering steel with good comprehensive performance and reasonable cost. Based on the composition of traditional weathering steel Q450NQR1 (0#), only the Ni content is changed to obtain weathering steels with different Ni contents. Then 5 kinds of Ni-containing weathering steels (respectively numbered 1#~5#) with Ni content in the range of 1% to 5% were smelted in a 25kg vacuum induction furnace. The chemical composition is shown in Table 2. According to the periodic infiltration corrosion test method of weathering steel for railways (TB / T2375-93) and the corrosion test method of steel bars in a chloride ion environment (YB / T4367-2014), the test parameters are set ...

Embodiment 2

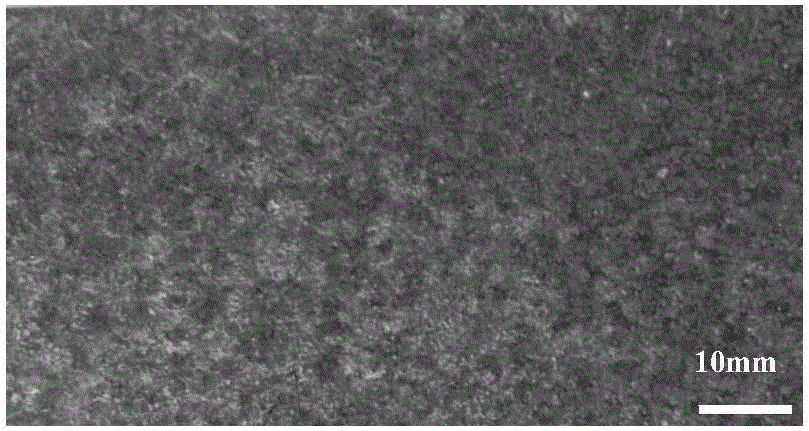

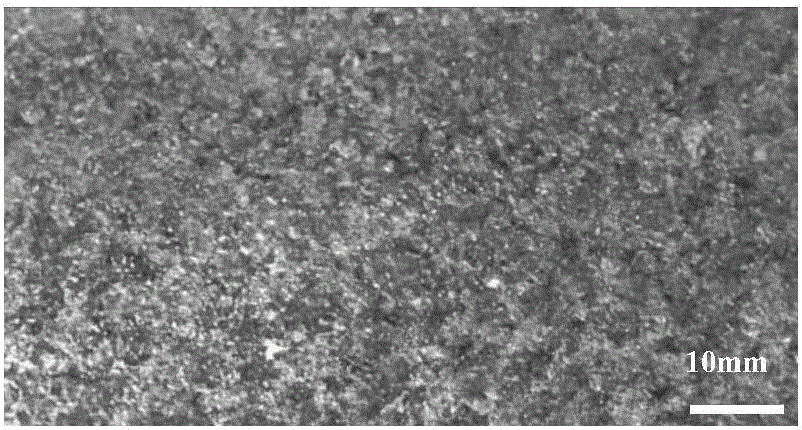

[0040] Example 2 The actual exposure test of weathering steel with different Ni content in Xisha, South China Sea

[0041] The test steel was the same as that in Example 1, and the actual exposure test was carried out in Xisha, South China Sea for 2 years, and the exposure time period was from October 2014 to October 2016. figure 2 It is the macroscopic corrosion photo of the test steel actually exposed to the sun.

[0042] Table 3 embodiment 1 and 2 corrosion test results

[0043]

[0044] Table 3 is the corrosion rate and relative corrosion rate data of Examples 1 and 2. From the two test conditions, it can be seen that the increase of Ni helps to improve the corrosion resistance of the test steel to high humidity and heat, marine atmosphere. When the Ni content exceeds 3%, the corrosion rate has a significant downward trend, which is 40% lower than that of the traditional Q450NQR1 weathering steel. , It is more than 50% lower than that of Q345 carbon steel, and the co...

Embodiment 3

[0046] On the basis of Examples 1 and 2, select 3# test steel and add microalloying elements Mo, Sn, Sb and RE to obtain the steel of the present invention. The steel of the present invention and the comparison steel Q345 carbon steel and Q450NQR1 traditional weathering steel were subjected to laboratory periodic infiltration corrosion test. The test condition parameters were the same as those in Example 1, and the test cycle nodes were set to 24h, 48h, 72h, and 96h. Table 4 is the chemical composition of the inventive steel in this example, and Table 5 is the results of the corrosion test data. Table 6 is the test results of the mechanical properties of the steel of the present invention.

[0047] Chemical composition (wt%) of steel of the present invention of table 4

[0048]

[0049] The corrosion test data of table 5 steel of the present invention and contrast steel

[0050]

[0051] The mechanical performance test result of table 6 steel of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com