A method for improving the quality of doped diamond-like carbon film

A diamond film, high-quality technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of uneven carbon plasma density distribution, difficult to achieve film quality, etc., and achieve friction coefficient controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

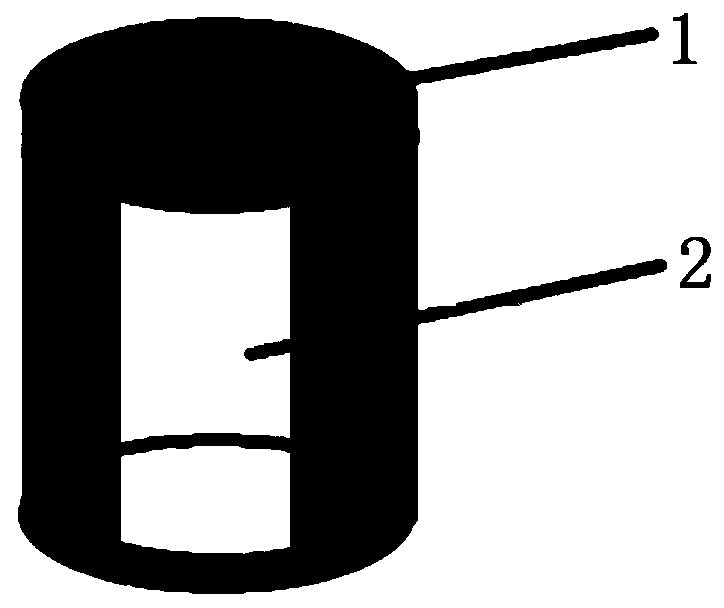

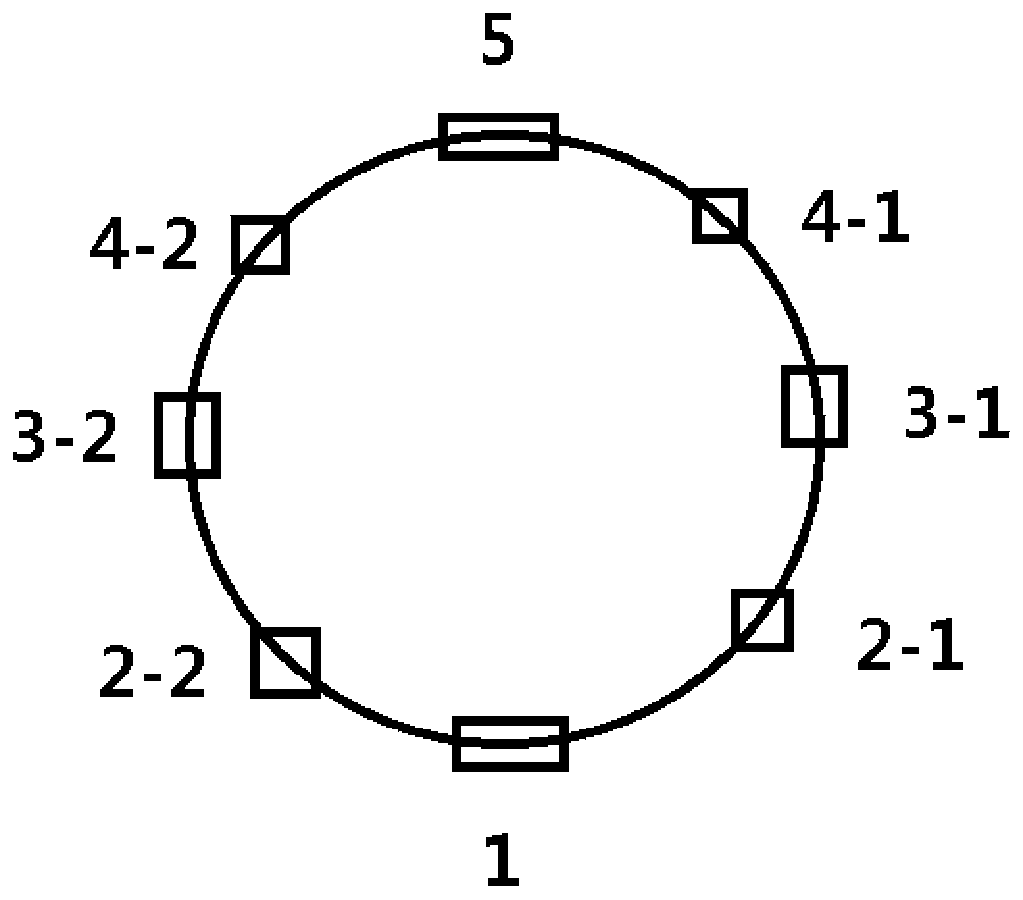

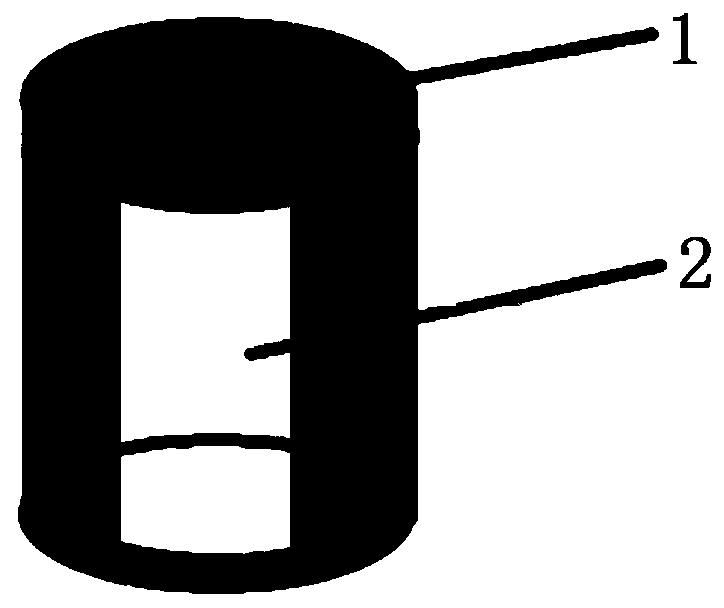

[0020] In order to solve the current problems of film brittleness and bonding force deviation around the workpiece, which do not meet the requirements of industrial applications, this embodiment provides a method for improving the quality of the doped diamond-like film layer, and plasma chemical vapor deposition doping is carried out on the workpiece. Before the diamond-like film layer, a shielding device is placed around the rotating workpiece. figure 1 The schematic diagram of the structure of the shielding device provided by the embodiment of the present invention, such as figure 1 As shown, the shielding device has a shielding device body 1 and an opening 2 . Preferably, in order to selectively deposit plasma with a certain plasma density, the opening angle of the opening 2 of the shielding device can be adjusted. During the deposition process, the opening 2 of the shielding device faces the plasma outlet, and the shielding device body 1 does not rotate with the workpiece...

Embodiment 2

[0026] Without adding a screen device, the cylindrical workpiece was deposited for 300 minutes while the workpiece was fixed, and the performance of the film layer in the circumferential direction was tested. The test results are shown in Table 1 below.

[0027]

[0028] Table 1

[0029] It can be seen from Table 1 that without adding a screen device and depositing when the cylindrical workpiece is fixed, the brittleness and bonding force of the obtained film layer meet the requirements, and some deviations, that is, the uniformity of the obtained film layer is not enough.

Embodiment 3

[0031] No screen device was added, and the cylindrical workpiece was deposited for 300 minutes during autobiography, and the performance of the film layer in the circumferential direction was tested. The test results are shown in Table 2 below.

[0032]

[0033] Table 2

[0034] It can be seen from Table 2 that without adding a screen device, the hardness of the obtained film layer is obviously soft when the cylindrical workpiece is self-propelled, and the film layer is brittle and has deviations in bonding force. The quality of the film layer cannot reach the level achieved when the workpiece is fixed. The achieved film quality does not meet the requirements for industrial applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com