Crucible for preparing large-section lead tungstate crystal and crystal growth method

A surface lead tungstate, crystal growth technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of easy cracking of crystals, achieve the effect of reducing thermal stress and avoiding the problem of crystal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of the above-mentioned PWO starting material. High-purity PbO, WO 3 The powder molar ratio is 1:1 and evenly mixed to obtain the PWO raw material. Or wash, dry and pulverize PWO single crystal as PWO raw material. As an example, PbO with a purity of 4N, WO 3 The powder is uniformly mixed at a molar ratio of 1:1, or small pieces of PWO single crystal are washed, dried, and crushed, and used as PWO raw material (powder or single crystal crushed material). Because the convective movement of the raw materials after melting in the furnace can make the raw materials mix evenly and fully react, so when selecting powder materials PbO, WO 3 The important thing is the purity, and the purity of 4N or higher is generally used. When using single crystal crushed material, there is no specific requirement for the particle size of the single crystal crushed material, it is suitable for loading into a crucible, and it is generally crushed to a particle size of <10mm.

...

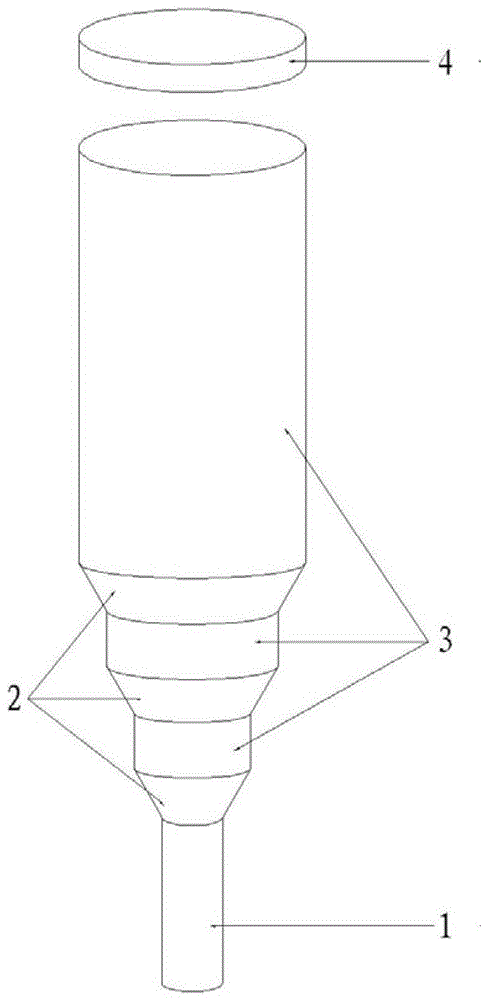

Embodiment 1

[0045] A metal platinum sheet with a thickness of 0.14mm is used to make a crucible with two shoulders with a circular cross-section. The size of the crucible seed crystal segment is φ15mm×50mm, and the angles of the two shoulders are both 30°. The height of the section shoulder is 15mm, the size of the equal-diameter section between the two shoulder sections is φ38mm×20mm, and the size of the upper equal-diameter section is φ55mm×320mm;

[0046] After the crucible descends and begins to grow crystals, the seed crystal segment grows at a rate of 1.6 mm / h, the first-stage shoulder segment grows at a rate of 1.0 mm / h, and the equal-diameter segment grows at a rate of 1.2 mm / h. Both the second-level shoulder section and the upper equal-diameter section grow at a descending rate of 0.8mm / h;

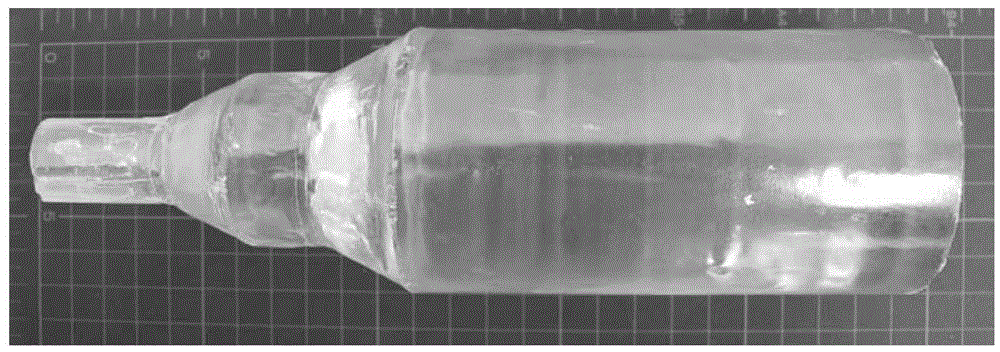

[0047] After the growth was completed and naturally cooled to room temperature, the crucible was taken out and peeled off to obtain a PWO crystal of φ55mm×210mm.

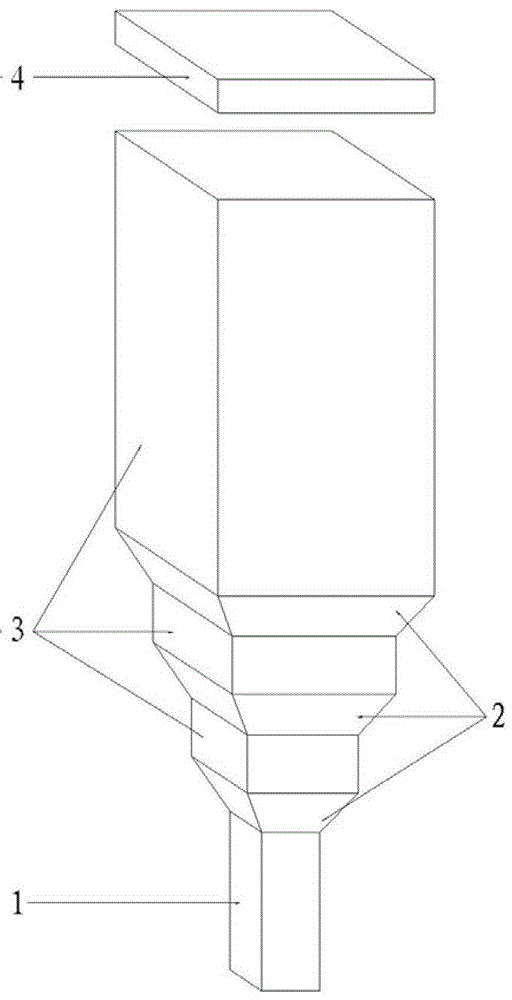

Embodiment 2

[0049] A metal platinum sheet with a thickness of 0.14mm is used to make a two-section shoulder-shoulder rectangular cross-section crucible, and the size of the crucible seed crystal section is 20×20mm 2 ×60mm, the angle of the two shoulders is 30°, the height of the first shoulder is 20mm, the height of the second shoulder is 15mm, and the size of the equal-diameter section between the two shoulders is 43×43mm 2 ×20mm, the size of the upper equal-diameter section is 60×60mm 2 ×250mm;

[0050] During the crystal growth process, the seed segment grows at a rate of 1.2mm / h, the first-stage shoulder segment grows at a rate of 0.8mm / h, the equal-diameter segment grows at a rate of 1.0mm / h, and the second The step shoulder section grows at a rate of 0.6mm / h; the upper equal diameter section grows at a rate of 0.8mm / h;

[0051] End of growth, get 60×60mm 2 ×160mm PWO crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com