Spiral trench-shaped electrostatic spinning device and use method of same

A spiral groove and electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the fluctuation of solvent volatilization concentration of the solution to be spun, non-oriented structure of nanofiber products, and low output of nanofibers and other issues, to achieve the effect of automatic supply and control, strengthened control, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

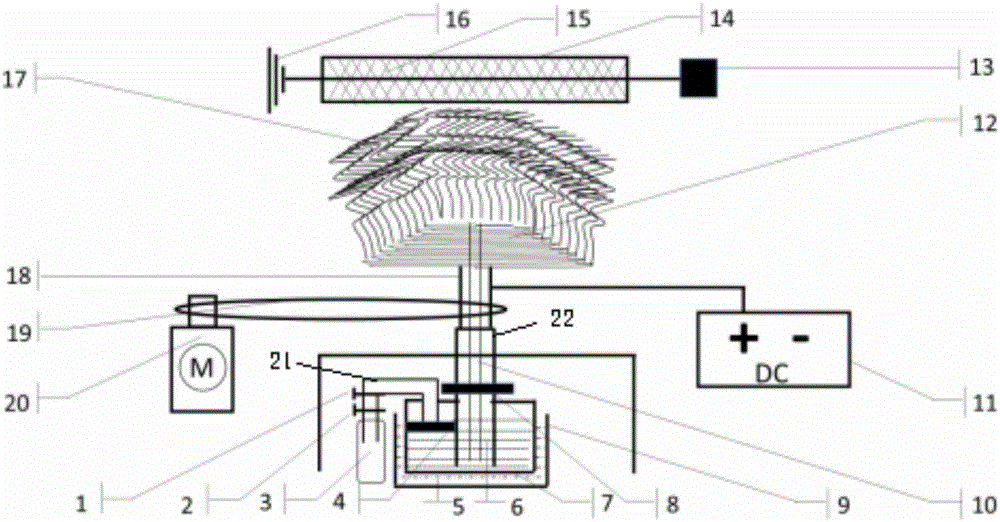

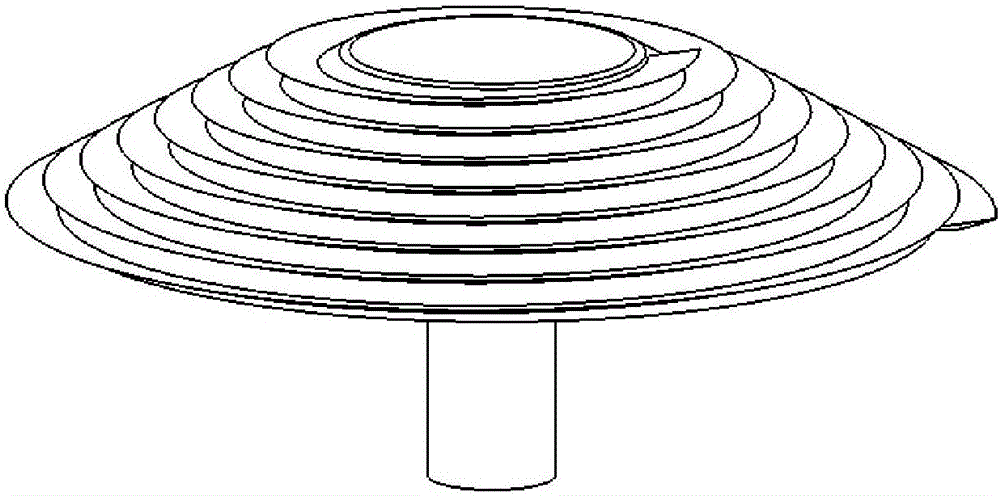

[0034] like figure 1 and figure 2As shown, a spiral groove electrospinning device includes a liquid supply system, a spiral groove spinning system and a nanofiber collection system, wherein the liquid supply system includes a gas cylinder 3, a spinning solution storage bottle 7, Oil bath 9 and catheter 10, described spinning solution storage bottle 7 is arranged in the oil bath 9, and described catheter 10 passes through rotating shaft 18, and one end is arranged on the bottom of spinning solution storage bottle 7, The other end is arranged on the top of the spiral groove nozzle 12, and the spinning solution storage bottle 7 and the catheter 10 form a connector structure to the top of the spiral groove nozzle 12, and the spinning solution storage bottle 7 passes through the trachea 21 and The gas cylinder 3 is connected, and the air pipe 25 is provided with a main valve 2 and a pressure reducing valve 1 in turn near the gas cylinder 3. The spiral groove spinning system inclu...

Embodiment 2

[0052] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 10%. The configured PAN / DMF polymer solution is injected into the spinning solution storage bottle 7, and the spinning solution storage bottle 7 and the spiral groove nozzle 12 are connected with the catheter 10. Add silicone oil 5 into the oil bath 9, and heat it to the set temperature of 40° C. with a hot stage. Open the middle switch 8 of the catheter tube 10, open the main valve 2 of the gas cylinder 3, adjust the pressure reducing valve 1 to push the piston 4 so that the high polymer solution 6 slowly flows into the spiral groove nozzle 12 through the catheter tube 10, so that the high polymer solution The substance solution 6 is present in a certain amount in the spiral groove-shaped shower head 12. Connect the metal drum 14 to the ground wire 16, turn on the motor 13 connected ...

Embodiment 3

[0054] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 12%. The configured PAN / DMF polymer solution is injected into the spinning solution storage bottle 7, and the spinning solution storage bottle 7 and the spiral groove nozzle 12 are connected with the catheter 10. Add silicone oil 5 into the oil bath 9, and heat it to the set temperature of 30° C. with a hot stage. Open the middle switch 8 of the catheter tube 10, open the main valve 2 of the gas cylinder 3, adjust the pressure reducing valve 1 to push the piston 4 so that the high polymer solution 6 slowly flows into the spiral groove nozzle 12 through the catheter tube 10, so that the high polymer solution The substance solution 6 is present in a certain amount in the spiral groove-shaped shower head 12. Connect the metal drum 14 to the ground wire 16, turn on the motor 13 connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com