Energy-saving diesel engine with multi-stage variable fuel supply transmission ratio and multi-operation mode

A diesel engine and transmission ratio technology, which is applied in the direction of liquid variable displacement machinery, engine components, machines/engines, etc., can solve the problems of inflexible switching operation mode, fixed and unchangeable transmission ratio, high crankshaft and camshaft speed, etc., to achieve Improve fuel supply efficiency and fuel supply stability, improve fuel economy, and reduce fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

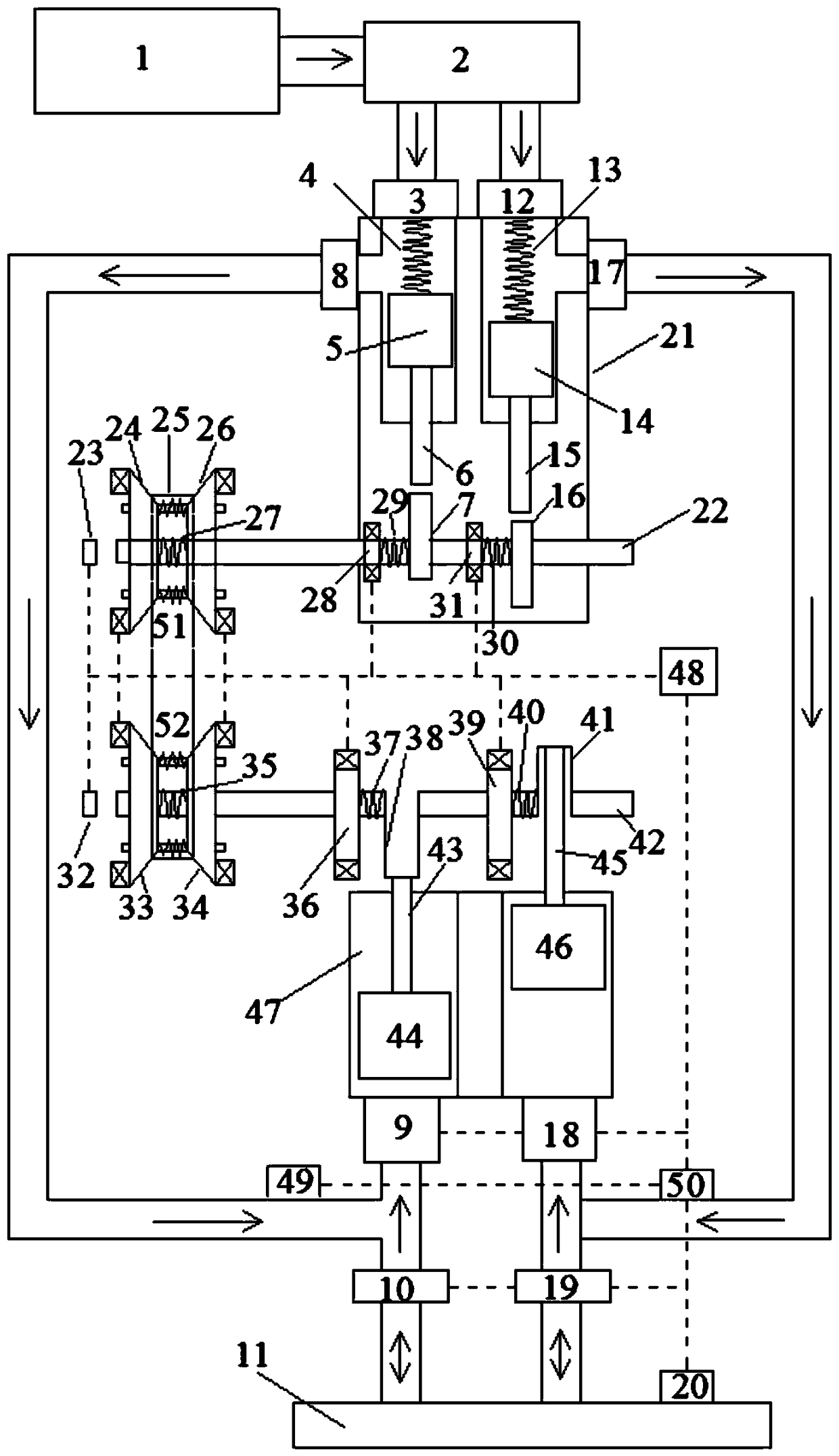

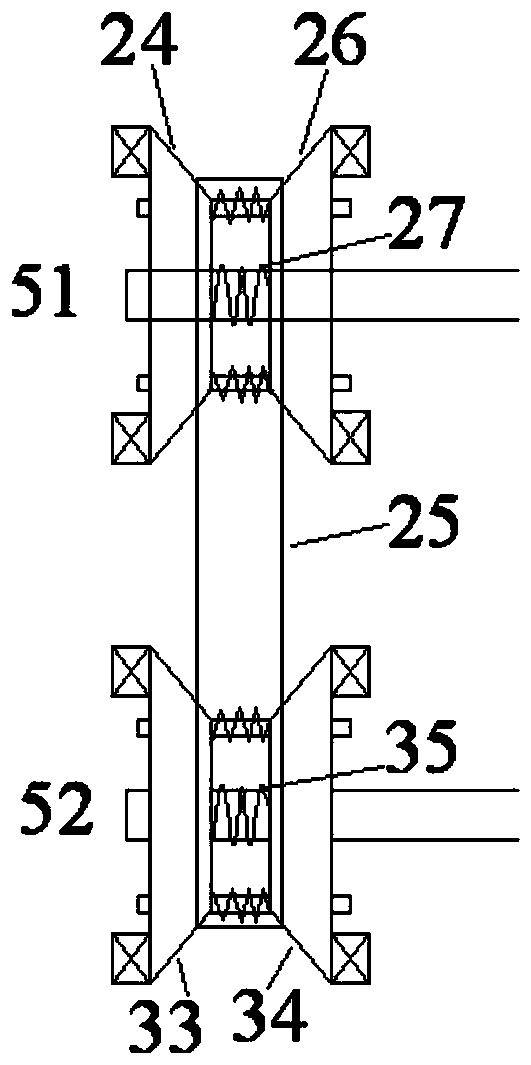

[0018] Example: see figure 1 and figure 2 , in the figure, 1-fuel tank, 2-diesel filter, 3-inlet valve A, 4-plunger A return spring, 5-plunger A, 6-push rod A, 7-cam A, 8- Outlet valve A, 9-electrically controlled fuel injector A, 10-electrically controlled one-way valve A, 11-accumulation energy storage tank, 12-inlet valve B, 13-plunger B return spring, 14-column Plug B, 15-Push rod B, 16-Cam B, 17-Oil outlet valve B, 18-Electronic control injector B, 19-Electronic control check valve B, 20-Oil pipe pressure sensor C, 21-High pressure oil pump , 22-high pressure oil pump camshaft, 23-camshaft speed sensor, 24-camshaft pulley A, 25-steel belt, 26-camshaft pulley B, 27-camshaft pulley return spring, 28-high pressure oil pump A Cylinder driver, 29-high pressure oil pump cylinder A driver return spring, 30-high pressure oil pump cylinder B driver return spring, 31-high pressure oil pump cylinder B driver, 32-crankshaft speed sensor, 33-crankshaft pulley A, 34-crankshaft belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com