High-strength plastic pipe and network application system thereof

A high-strength plastic and network-applied technology, applied in the field of pipelines, can solve the problems of easy corrosion and rust of pipelines, poor impact resistance, low compressive strength, etc., and achieve the effects of not being easy to break, increasing compressive strength, and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

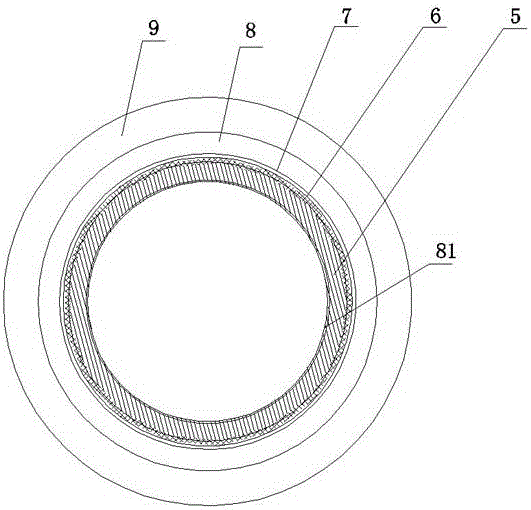

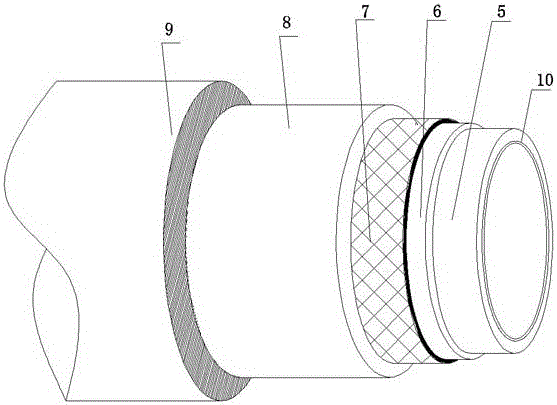

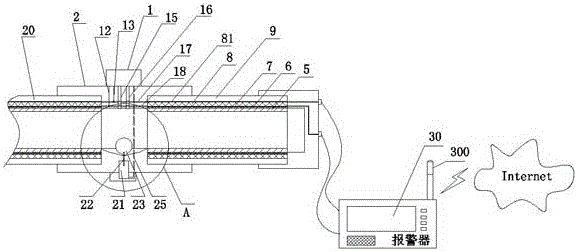

[0013] like Figure 1-5 As shown, the high-strength plastic pipe and its network application system include a pipe 100 and a pipe joint 2, wherein the innermost layer of the pipe is a PE core pipe 5, the PE core pipe is wrapped with a first bonding layer 6, and the outermost layer of the first bonding layer is 6 is wrapped with a stainless steel wire mesh layer 7, the stainless steel mesh layer 7 is wrapped with a PE intermediate bonding layer 8, the outer wall of the PE intermediate bonding layer 8 is wrapped with a HDPE weather-resistant layer 9 bottles, the inner wall of the PE core tube is provided with a nano-silver film layer 10, and the pipe Embedded metal wires 81 are also embedded therein. The embedded metal wire 81 and the stainless steel wire mesh layer 7 form a data transmission loop. If the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com