Full-time four-wheel-drive automobile braking force detection apparatus

A technology of automobile braking and braking force, which is applied in the direction of measuring devices, vehicle testing, force/torque/power measuring instruments, etc., and can solve the problem of high operation and environmental requirements, poor repeatability, and damage to vehicle differentials or gearboxes and other problems, to achieve the effect of simple operation, solving detection problems, and avoiding the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

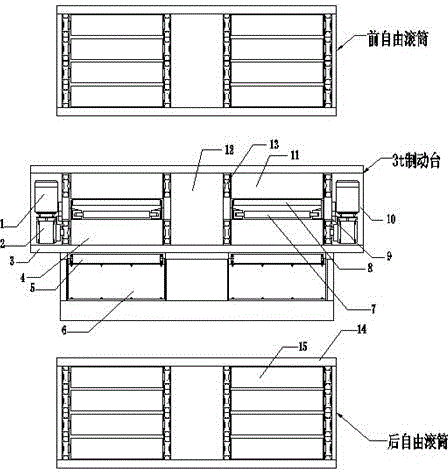

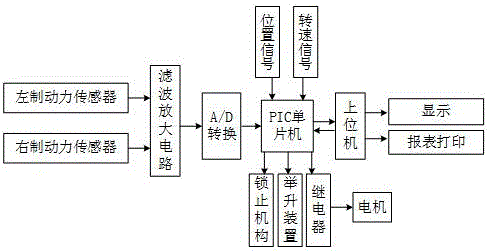

[0025] In this embodiment, the full-time four-wheel drive vehicle braking force detection device is tested, and the full-time four-wheel drive vehicle braking force detection device is installed at a certain place testing station A, and three types of full-time four-wheel drive vehicles Subaru Impreza, Volkswagen Tiguan, and Audi are selected. As a test vehicle, Q5 was driven on the braking force detection device of a full-time four-wheel drive vehicle for three braking force detections. According to GB7258-2012 "Motor Vehicle Operation Safety Technical Conditions" and GBT13564-2005 "Drum Reaction Vehicle Braking Test Bench", the comparative test is carried out according to the following steps:

[0026] 1) According to the instructions, install the mechanical platform and system instruments, and park the test vehicle within the width limit mark of the test road after checking.

[0027] 2) Turn on the power, turn on the computer, start the host computer test software, log in to...

Embodiment 2

[0041] In this embodiment, the full-time four-wheel drive vehicle braking force testing device is calibrated. A full-time four-wheel drive vehicle braking force testing device is installed in a manufacturer B in a certain place, and the calibration frame is fixed on the roller. Dynamic calibration. Use a dedicated calibration device to sequentially load the mass of weights ( m i ) to full scale, and then reduce the mass of weights in turn ( m i ) to zero, measure the indicated value of the braking force AD of the left and right wheels corresponding to the set calibration points, repeat the measurement two or three times for each calibration point, and take the arithmetic mean value.

[0042]In the actual calibration of this device, L / R is 10, and the measurement data are shown in Table 4.

[0043] Table 4 Braking force calibration measurement data

[0044] Loading weight value / kg 50 100 150 200 250 300 350 400 Braking force value / daN 490 980 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com