Automatic experiment and analysis device for measuring air relative pressure coefficient

A relative pressure and analysis device technology, applied in the field of measurement, can solve the problems that the data cannot be collected, processed, analyzed and displayed in real time, the temperature and heat balance in the bubble cannot be guaranteed, and the data cannot be recorded, so as to prevent dry burning, ensure consistency, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

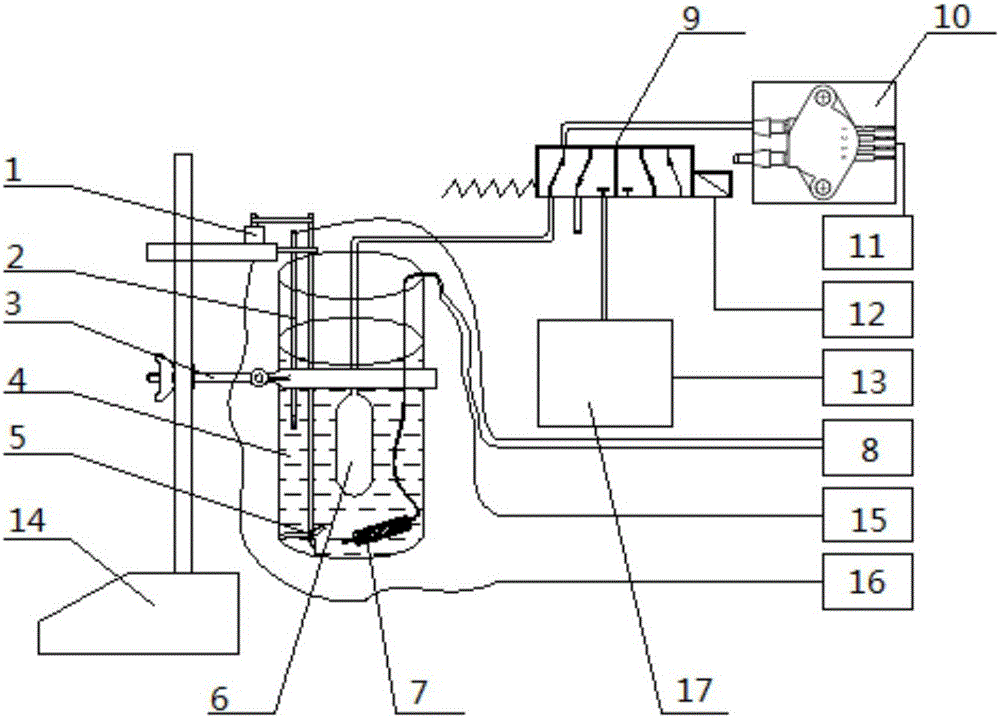

[0021] Such as figure 1 As shown, the automatic experiment and analysis device for measuring air relative pressure coefficient of the present invention comprises: stirring motor 1, fixture device 3, beaker 4, stirring blade 5, support 14, air bubble 6, heating rod assembly 7, mechanical pump 17, two Five-way electromagnetic reversing valve 9, pressure detection device 10, pressure detection module 11, electromagnet drive unit 12, mechanical pump drive unit 13, PWM control unit 15, temperature measurement module 8, stirring motor drive unit 16.

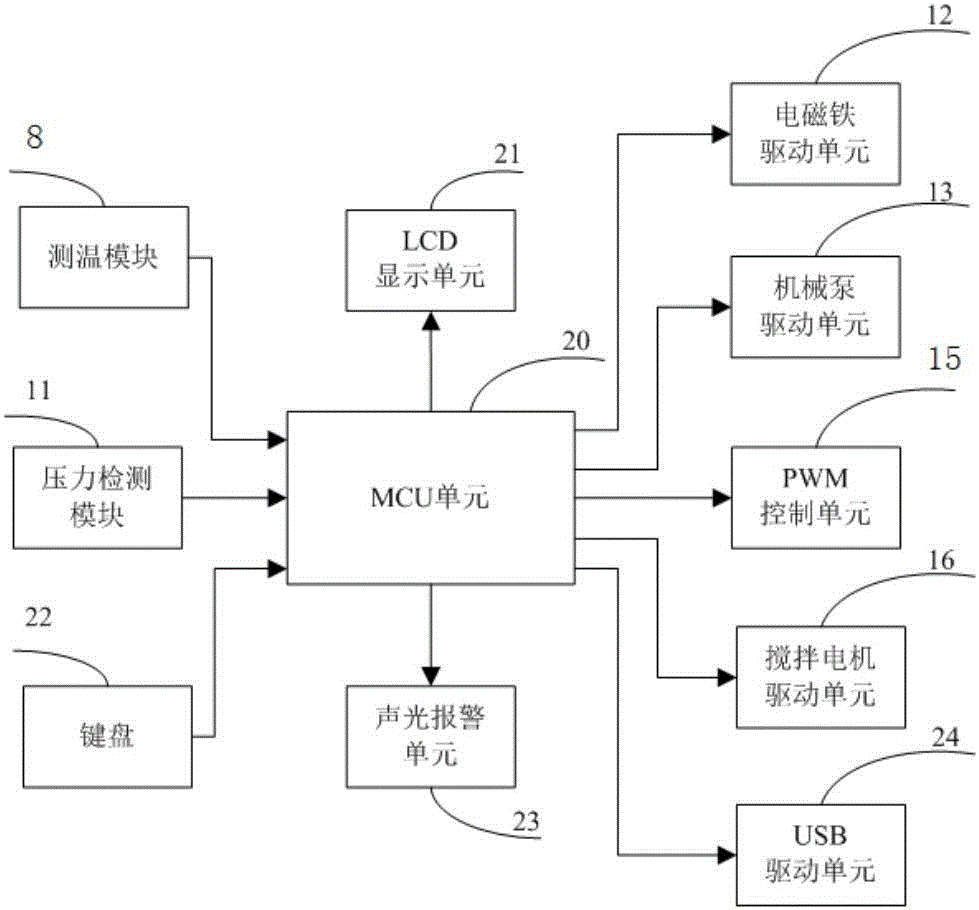

[0022] Such as figure 2 As shown, the automatic experiment and analysis system for measuring air relative pressure coefficient of the present invention includes: MCU unit 20 , LCD display unit 21 , keyboard 22 , sound and light alarm unit 23 , and USB drive unit 24 . The MCU unit 20 has PWM output, SPI communication, USB drive unit and related functions, and has data power-down protection function. Among them, the PWM output is a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com