Vertical-cavity surface-emitting laser array for full-color display illumination

A technology of vertical cavity surface emission and laser array, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., to achieve the effects of wide color gamut display lighting applications, simplified process steps, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

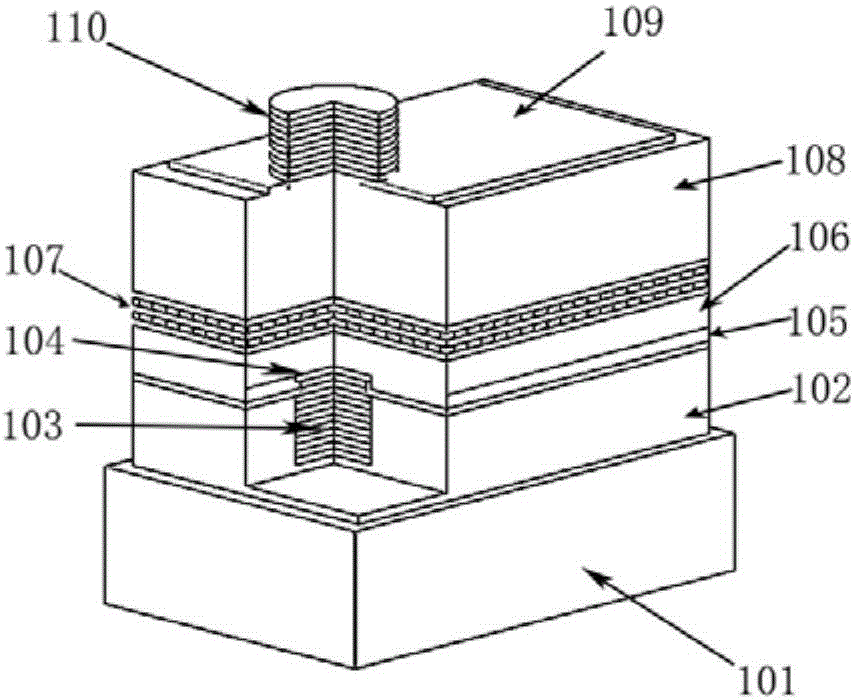

[0019] see figure 1 , the embodiment of the present invention is provided with a heat dissipation copper substrate 101, a bonding layer 102, a current spreading and P-type electrode 104, a current confinement layer 105, a P-type GaN layer 106, a quantum dot active region 107, and an N-type GaN layer from bottom to top. layer 108 and N-type electrode 109; the N-type GaN layer 108, the quantum dot active region 107 and the P-type GaN layer 106 are sequentially grown on the heat dissipation copper substrate 101, and the current confinement layer 105 is deposited on the P-type GaN layer 106 A P-type current injection hole is opened in the current confinement layer 105, and the current expansion and P-type electrode 104 are gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com