Mobile phone rear cover with metal texture and preparation method thereof

A mobile phone back cover, metal texture technology, applied in branch equipment, telephone structure, telephone communication and other directions, can solve the problem of not being able to solve the problem of heating well, not improving the efficiency of radio transmission, etc., to achieve high yield and maintain texture And the effect of touch and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

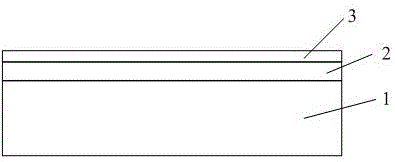

Image

Examples

preparation example Construction

[0095] Correspondingly, the present invention also discloses a method for preparing a mobile phone back cover with a metallic texture, including:

[0096] (1) The raw materials required for preparing the back cover of the mobile phone are mixed and pulped, and the ceramic casting plain sheet is obtained through a casting machine.

[0097] (2) Laminate the cast ceramic sheets.

[0098] (3) Laminating the laminated ceramic casting sheets.

[0099] Preferably, the stacked green sheets are laminated by a press, the pressure of the press is ≤ 15 MPa, and the above pressure is used to laminate the green sheets, so that the layers can be well bonded Together, and make the shape and size of the stacked blanks within a reasonable range, so that the isostatic pressing treatment can be performed later.

[0100] (4) Perform isostatic pressing on the laminated ceramic cast plain sheet.

[0101] Preferably, the pressure of the isostatic pressing treatment is 13-60 MPa.

[0102] (5) Debi...

Embodiment 1

[0111] (1) Formula:

[0112] (1), mobile phone back cover substrate

[0113] Zirconia 50 parts

[0114] Aluminum oxide 1 part

[0115] Yttrium oxide 0.1 part

[0116] Titanium oxide 0.1 part

[0117] 1 part adhesive

[0118] Dispersant 0.1 parts

[0119] Plasticizer 0.1 parts

[0120] 10 parts of solvent.

[0121] (2) The metal material is aluminum alloy.

[0122] (2) Preparation method:

[0123] (1) Mix and pulp the raw materials required for the preparation of the back cover of the mobile phone, and use a casting machine to obtain a ceramic cast plain sheet;

[0124] (2) Laminate ceramic casting sheets;

[0125](3) Laminating the laminated ceramic casting sheets;

[0126] (4) Perform isostatic pressing on the laminated ceramic casting sheet;

[0127] (5) Debinding the isostatically pressed ceramic casting sheet;

[0128] (6) Sintering the cast ceramic sheet after debinding treatment to obtain a ceramic sheet;

[0129] (7) Spray the metal material on the surface...

Embodiment 2

[0132] (1) Formula:

[0133] (1), mobile phone back cover substrate

[0134] Zirconia 60 parts

[0135] Aluminum oxide 2 parts

[0136] Yttrium oxide 0.2 parts

[0137] Titanium oxide 0.2 parts

[0138] Binder 5 parts

[0139] Dispersant 2 parts

[0140] 2 parts plasticizer

[0141] 20 parts of solvent.

[0142] (2) The metal material is titanium alloy.

[0143] (2) Preparation method:

[0144] (1) Mix and pulp the raw materials required for the preparation of the back cover of the mobile phone, and use a casting machine to obtain a ceramic cast plain sheet;

[0145] (2) Laminate ceramic casting sheets;

[0146] (3) Laminating the laminated ceramic casting sheets;

[0147] (4) Perform isostatic pressing on the laminated ceramic casting sheet;

[0148] (5) Debinding the isostatically pressed ceramic casting sheet;

[0149] (6) Sintering the cast ceramic sheet after debinding treatment to obtain a ceramic sheet;

[0150] (7) Spray the metal material on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com