A method of purifying lignin by subjecting a slurry comprising lignin to an electric field

一种纯化方法、木质素的技术,应用在木质素衍生物、化学仪器和方法、分离方法等方向,能够解决不足以有效移除灰分和离子最后部分等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

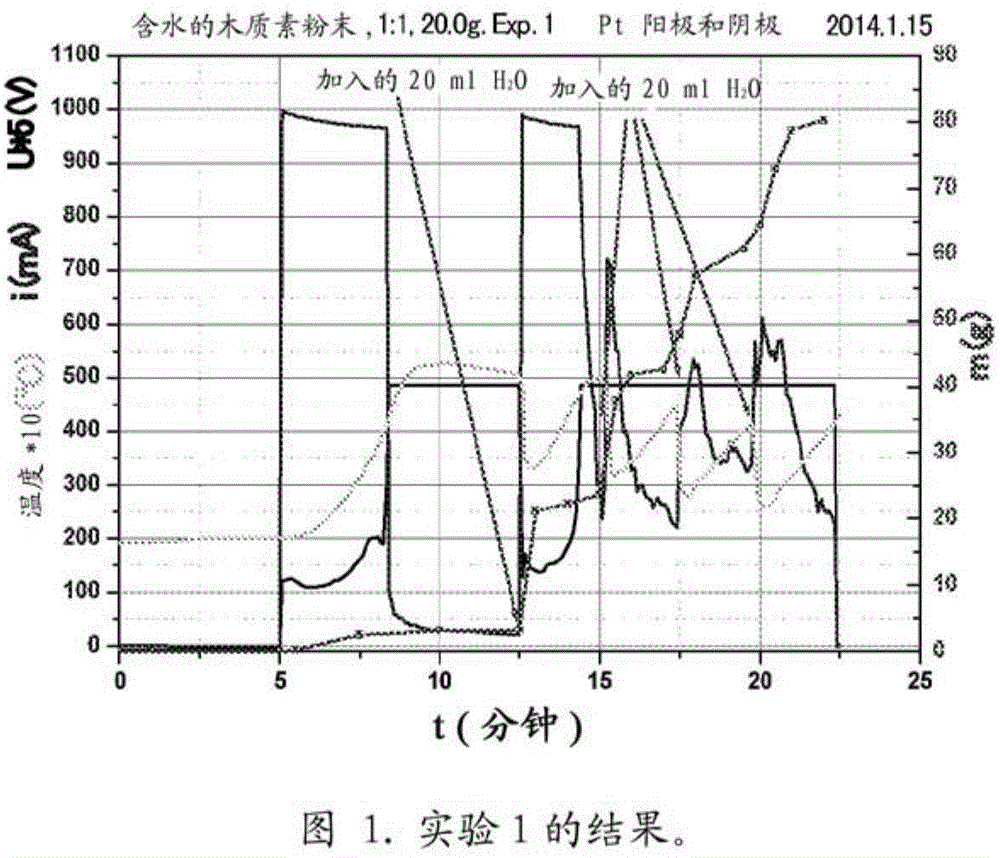

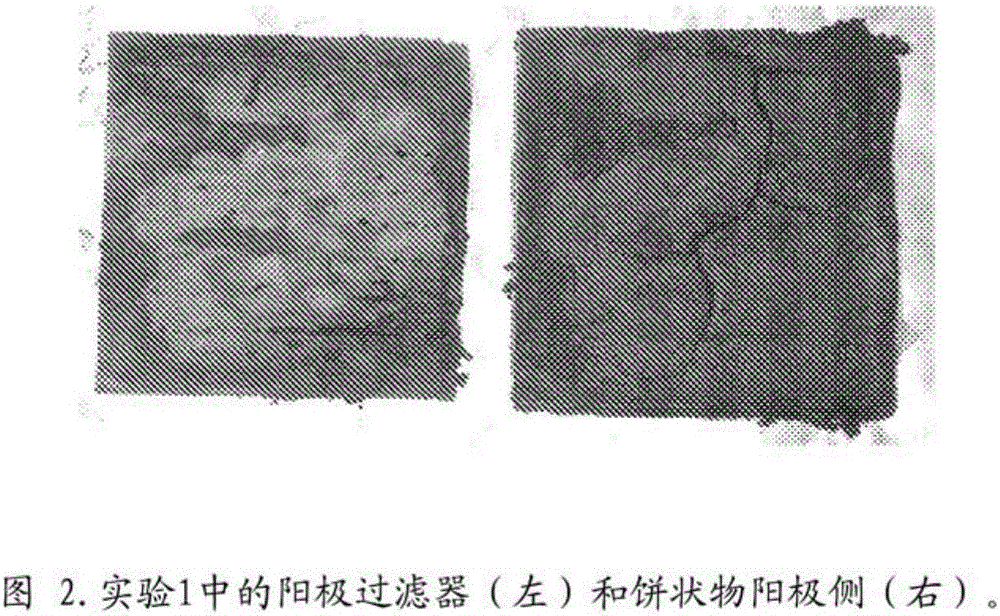

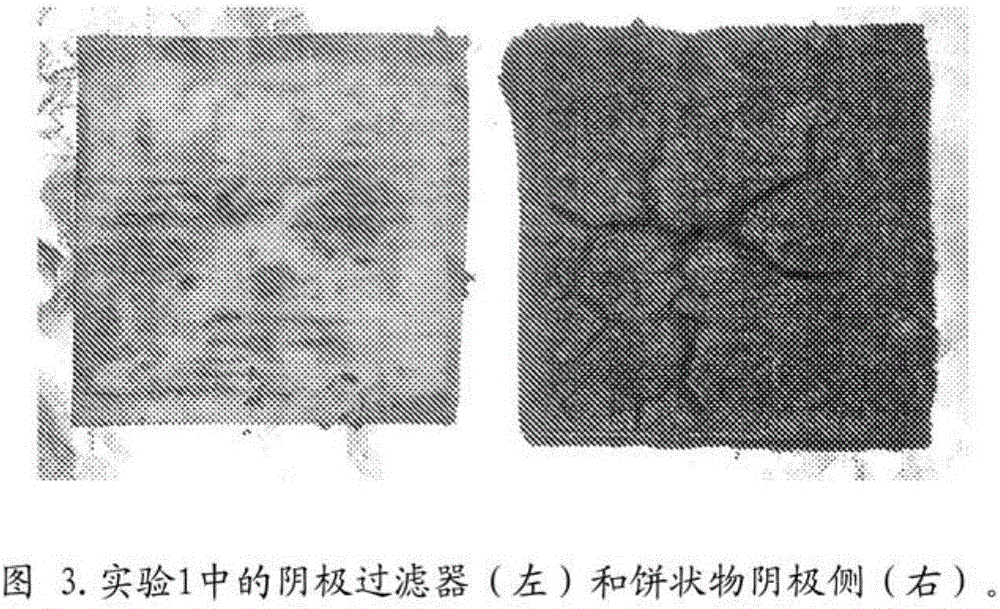

Image

Examples

Embodiment Construction

[0020] Throughout the specification the expression "lignin" is intended to encompass any lignin that may be used in the method according to the first aspect. The lignin can be ground wood-lignin, organosolvent lignin, sulfite lignin, alkaline lignin, steam explosion lignin, steam explosion lignin, from a variety of lignocellulosic materials. Acid hydrolysis of lignin. Preferably, the lignin is alkaline lignin. It may, for example, be kraft lignin. In addition to kraft lignin, other types of lignin such as natural lignin, bismuth Alkane lignin (dioxiane lignin) or enzymatically released lignin. Lignin is preferably obtainable by using the method disclosed in EP1794363. Not limited to kraft lignin or lignin-containing liquid suspensions, but of course lignosulfonates (derived from kraft lignin, Soda AQ and sulphite pulping), in ionic liquid or solvent-based processes Obtained lignin fraction, chemically modified lignin fraction, chemically activated lignin, enzyme-treated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com