Synthesis method of solvent blue 102

A synthesis method and solvent technology, applied in the field of synthesis of solvent blue 102, can solve the problems of lowering product quality, affecting product hue, and high production cost, and achieve the effects of low production cost, good color and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

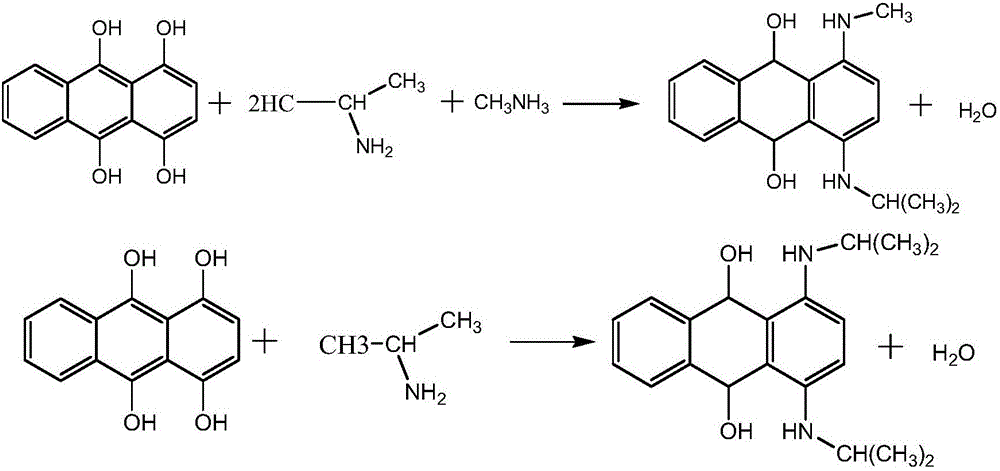

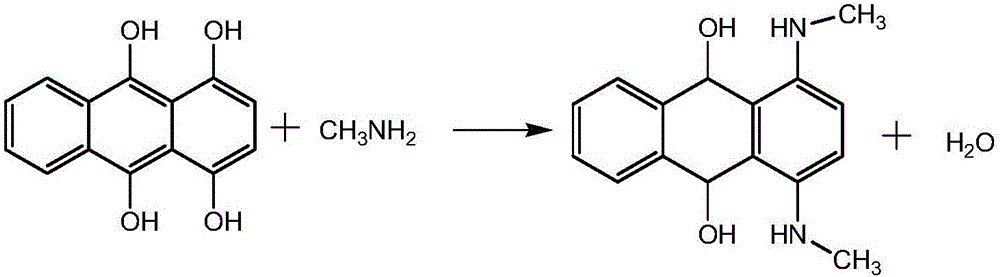

Image

Examples

preparation example Construction

[0023] A kind of synthetic method of solvent blue 102, concrete steps are as follows,

[0024] Put isopropanol, polyethylene glycol, and 1,4-dihydroxyanthraquinone leuco into the container in sequence, stir evenly, add monomethylamine and isopropylamine mixed aqueous solution, heat up to 70-75°C and react for more than 5 hours, After the reaction, desolventize to 80-85°C under normal pressure, cool down to 40-45°C (steam out monomethylamine and isopropylamine), add water, sodium hydroxide, copper sulfate, open the reaction vessel, Stir at ℃ for more than 10 hours, filter, wash, dry and discharge.

[0025] Among them, the mass ratio of 1,4-dihydroxyanthraquinone leucosome to isopropanol is 1: (5-7.5), and the mass ratio of 1,4-dihydroxyanthraquinone leucosome to polyethylene glycol is 1 : (0.05-0.25), the mass ratio of 1,4-dihydroxyanthraquinone leucosome and 70wt% monomethylamine is 1: (0.357-0.5), 1,4-dihydroxyanthraquinone leucosome and isopropylamine The mass ratio of 1: ...

Embodiment 1

[0028] In a 500mL four-neck flask equipped with a mechanical stirrer and a thermometer, add 100g of isopropanol, 1g of polyethylene glycol, 20g of 1,4-dihydroxyanthraquinone leuco, and after stirring evenly, add 70wt% monomethylamine A mixed solution of 7.14 g, 7 g of isopropylamine, and 9.5 g of water was heated up to 70° C., and the reaction was carried out for 5 hours. After the reaction, the solution was precipitated to 85°C under normal pressure, cooled to 40°C, 200g of pure water, 4g of sodium hydroxide, and 0.5g of copper sulfate were added in sequence, and stirred at 45°C for 10 hours. After stirring, filter, wash, and dry to obtain 24.5 g of the target product (including: 21.41 g of 1-methylamino-4-isopropylaminoanthraquinone, 1.77 g of 1,4-bis(methylamino)anthraquinone, 1,4 - Di(isopropyl)aminoanthraquinone 1.07g), yield 1.22, shade (DC0.6, DH0.2, intensity 101.0).

Embodiment 2

[0030] In a 500mL four-necked flask equipped with a mechanical stirrer and a thermometer, add 120g of isopropanol, 2g of polyethylene glycol, and 20g of 1,4-dihydroxyanthraquinone leuco. After stirring evenly, add 70wt% monomethylamine 9. A mixed solution of 9.28 g, 10 g of isopropylamine, and 55 g of water was heated up to 73° C., and the heat preservation reaction was carried out for 6 hours. After the reaction is over, desolvate to 85°C under normal pressure, cool down to 40°C, add 250g of pure water, 5g of sodium hydroxide, and 1g of copper sulfate in sequence, and stir at 45°C for 14 hours. After stirring, filter, wash, and dry to obtain 24.35 g of the target product (including: 20.68 g of 1-methylamino-4-isopropylaminoanthraquinone, 2.21 g of 1,4-bis(methylamino)anthraquinone, 1,4 -Di(isopropyl)aminoanthraquinone 1.34), output rate 1.21, shade (DC0.8, DH0.5, intensity 102.3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com