Ultrasonic supercritical-low temperature vacuum frying drying technology of mushroom

A low-temperature vacuum frying and drying process technology, applied in food preservation, fruit and vegetable preservation, heating preservation of fruits/vegetables, etc., can solve the problems of easy contamination of fresh mushrooms, short shelf life of mushrooms, incomplete drying, etc. The risk of mushroom bursting, the short drying time, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

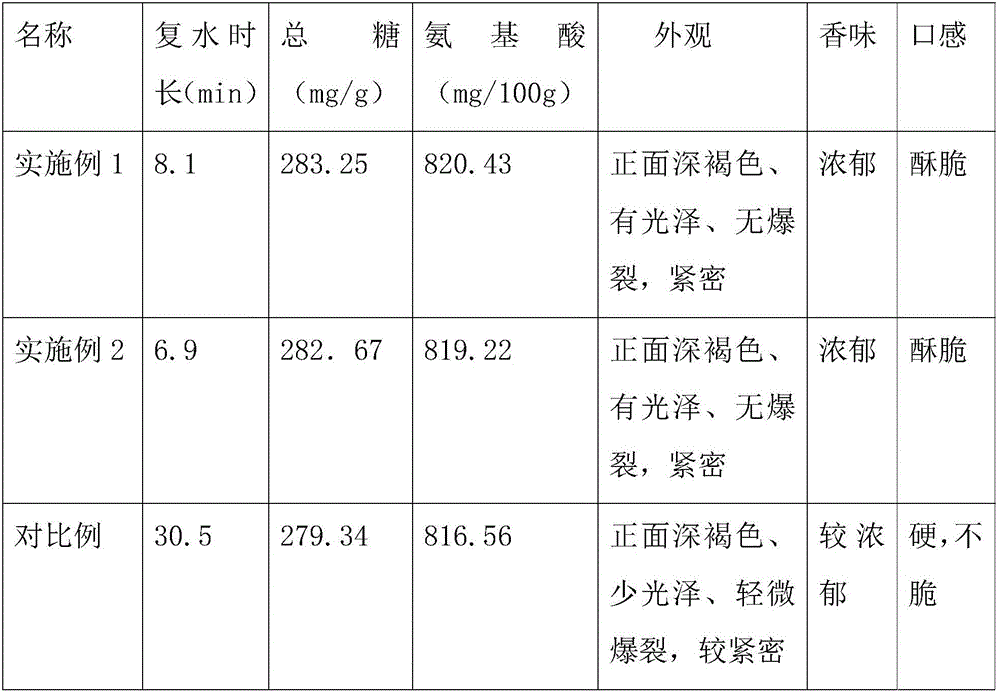

Examples

Embodiment 1

[0029] An ultrasonic supercritical-low temperature vacuum frying and drying process of shiitake mushrooms, comprising the following steps:

[0030] (1) Grading the fresh shiitake mushrooms purchased in the supermarket according to the Chinese shiitake mushroom grading standard, washing the graded shiitake mushrooms with salt water and clear water, removing impurities, and then cutting them into thin slices with a thickness of 1 cm;

[0031] (2) Ultrasonic Chinese herbal medicine compound enzyme treatment: while ultrasonic (ultrasonic power 100W, frequency 20kHz), put the shiitake mushrooms processed in step (1) into the mixed solution of Chinese herbal medicine compound enzyme (Chinese herbal medicine liquid and compound enzyme solution by volume ratio 1 :60 mixed solution, the compound enzyme solution is in the mixed solution of cellulase, hemicellulose plum, pectinase and bromelain with a volume ratio of 1:1:1:1) with a mass fraction of 1.5%, soaking for 30min Then take it o...

Embodiment 2

[0038] (1) Grading the fresh shiitake mushrooms purchased in the supermarket according to the Chinese shiitake mushroom grading standard, washing the graded shiitake mushrooms with salt water and clear water successively, and removing impurities;

[0039] (2) Ultrasonic Chinese herbal medicine compound enzyme treatment: while ultrasonic (ultrasonic power 100W, frequency 20kHz), put the shiitake mushrooms processed in step (1) into the mixed solution of Chinese herbal medicine compound enzyme (Chinese herbal medicine liquid and compound enzyme solution by volume ratio 1 :70 mixed solution, the compound enzyme solution is cellulase, hemicellulose plum, pectinase and bromelain mixed solution with a volume ratio of 1:1:1:1) with a mass fraction of 1.5%, soaking for 45min Then take it out, rinse it with clean water and drain the surface water for later use;

[0040] (3) Ultrasonic supercritical carbon dioxide pre-drying: place the shiitake mushrooms treated in step (2) in a sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com