Double-spindle box four-cutter head eight-shaft cylinder boring machine and control method thereof

A technology of cylinder boring machine and headstock, which is applied to the parts of boring machine/drilling machine, manufacturing tools, boring/drilling, etc. It can solve the problems of low fixture automation level and no automatic adjustment, etc., and achieve compact product space, Improved production efficiency and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

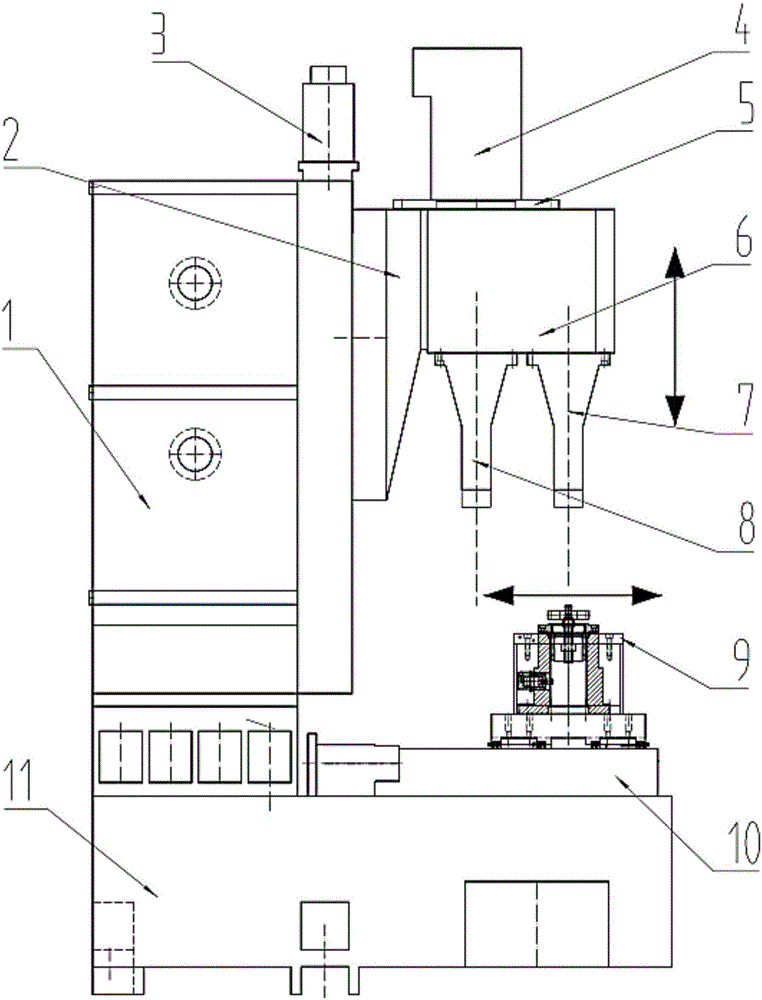

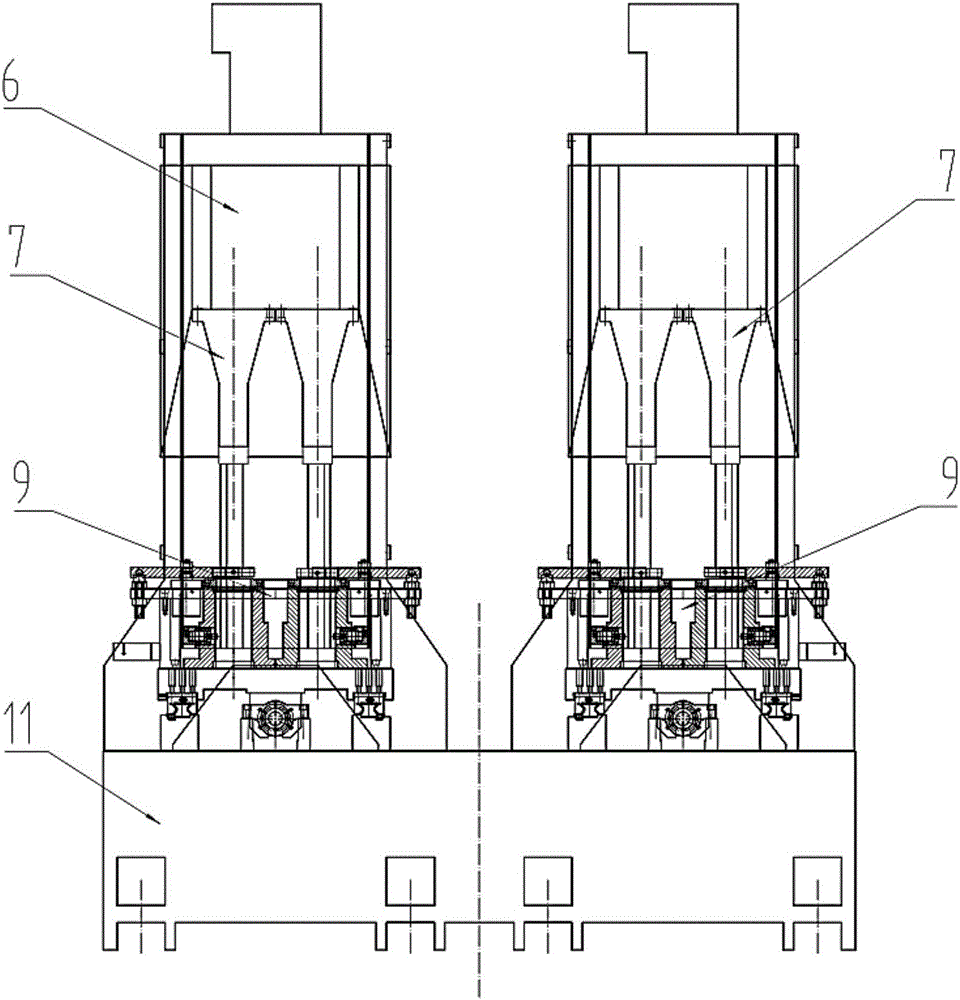

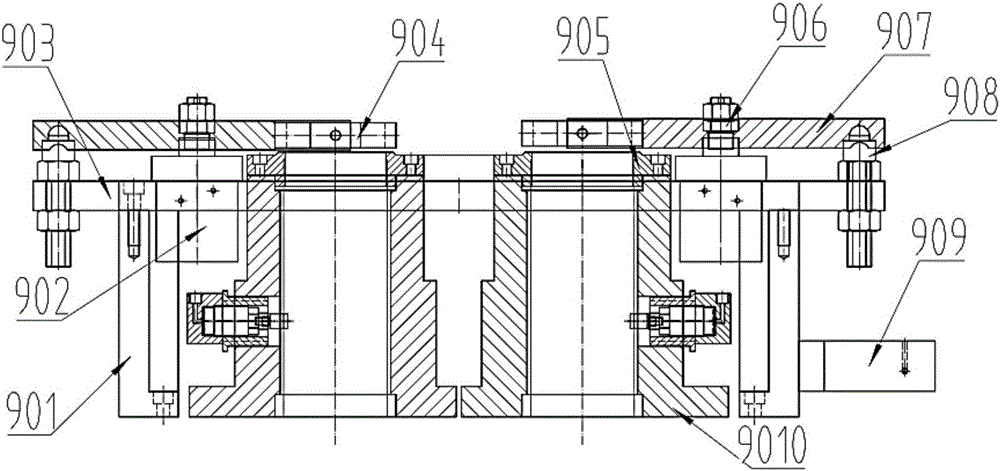

[0036] figure 1 , 2 , 3, 4, 5, and 6, a double-headstock four-blade eight-axis cylinder boring machine includes a base 11, a column 1, a headstock mounting block 2, a headstock screw 3, a spindle motor 4, and a motor mounting plate 5 , spindle box 6, rough boring tool 7, fine boring tool 8, tooling fixture 9 and workbench 10, and tooling side plate 901 of tooling fixture 9, pressure plate oil cylinder 902, tooling plate 903, pressure ring 904, workpiece ferrule 905, universal bearing 906, pressure plate 907, positioning ejector rod 908, oil pipe seat 909, tooling sleeve 9010, guide sleeve 9011, support cylinder rear seat 9012, support cylinder rear seat oil hole 9012h, support cylinder 9013 and positioning head 9014, And oil tank Y1 including hydraulic device, oil suction filter Y2, oil pump motor Y3, variable vane pump Y4, fuel filler Y5, liquid level gauge Y6, air cooler Y7, oil return pipeline Y8, oil inlet pipeline Y9, superimposed one-way Valve Y10, pressure reducing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com