Method for reducing deformation quantity of workpieces after laser cladding

A technology of laser cladding and deformation, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of low surface flatness of materials, optimize surface flatness, improve processing quality and efficiency, reduce workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

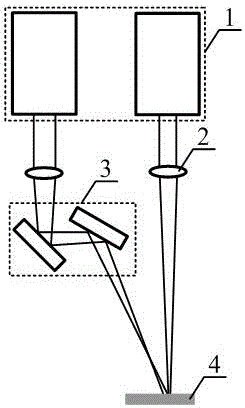

[0035] figure 1 and image 3 It shows a specific implementation of the method of reducing the deformation of the workpiece after laser cladding of the present invention, referring to figure 1 , the method for reducing the deformation of the workpiece after laser cladding in the specific embodiment of the present invention is applicable to the structure for reducing the deformation of the workpiece after laser cladding, including two stacked semiconductor lasers 1, two focusing mirrors 2, and a set of reflection Mirror group 3 and working surface 4.

[0036] The two semiconductor lasers 1 used are both made of one 915nm and one 976nm semiconductor laser stacked beams, each stack is composed of 20 bars, and the bars in the two stacked semiconductor lasers use fast and slow axes The collimating mirror collimates it, and the output power is 2kW.

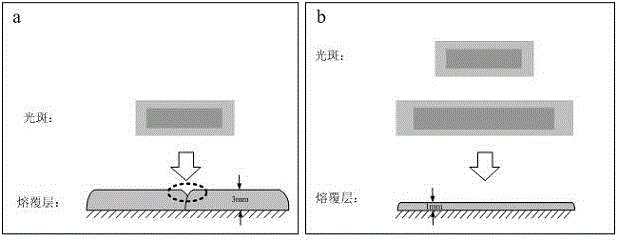

[0037] In the structure for reducing the deformation of the workpiece after laser cladding applicable to the method of reducing the ...

Embodiment 2

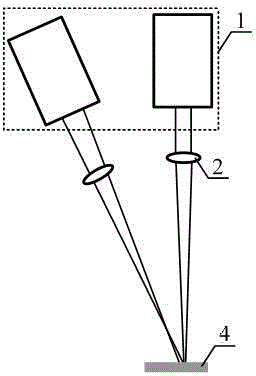

[0040] figure 2 Another specific implementation of the method for reducing the deformation of the workpiece after laser cladding of the present invention is shown. and figure 1 The specific implementation shown is different in that the reflector group 3 of the second optical path is removed, and the edge interval and irradiation angle of the two light spots on the working surface are adjusted directly by adjusting the position of the second semiconductor laser 1 . The working principle of the method for reducing the deformation of the workpiece after laser cladding in this embodiment is the same as figure 1 The specific embodiments shown are the same, so they will not be described here again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com