Damp-proof graphene composite heat dissipation film

A graphene composite and heat dissipation film technology, which is applied in synthetic resin layered products, electronic equipment, and other household appliances, can solve the problems of poor weather resistance and affect the use effect of heat dissipation film, so as to improve heat conduction effect, facilitate installation and The effect of using and solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

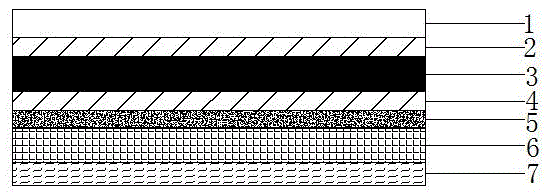

[0015] like figure 1 As shown, a moisture-proof graphene composite heat dissipation film comprises PET release film layer 1, first thermally conductive adhesive layer 2, graphite paper layer 3, second thermally conductive adhesive layer 4, graphene layer 5, PET substrate layer 6, water-absorbent resin layer 7.

[0016] The design of the present invention is to coat a layer of superabsorbent resin on one side of the PET substrate 6 to form a water-absorbent resin layer 7. The water-absorbent resin layer 7 is polyacrylic acid sodium salt, polyacrylonitrile hydrolyzate, vinyl acetate and methyl acrylate. One of the copolymer or modified polyvinyl alcohol water-absorbing resin, the other side of the PET substrate 6 utilizes a chemical deposition method to deposit a layer of graphene layer 5, and the graphene layer 5 and graphite paper layer 3 utilize the first The two thermally conductive adhesive layers 4 are bonded together, and finally, the graphite paper layer 3 and the PET r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com