Method and device for preparing polyether amine

A technology of polyether amine and polyether polyol, which is applied in the field of organic chemical industry, can solve the problems of easy deactivation of catalysts, uneven loading, easy agglomeration, etc., and achieve large-scale continuous industrial production, excellent activity, and simple separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

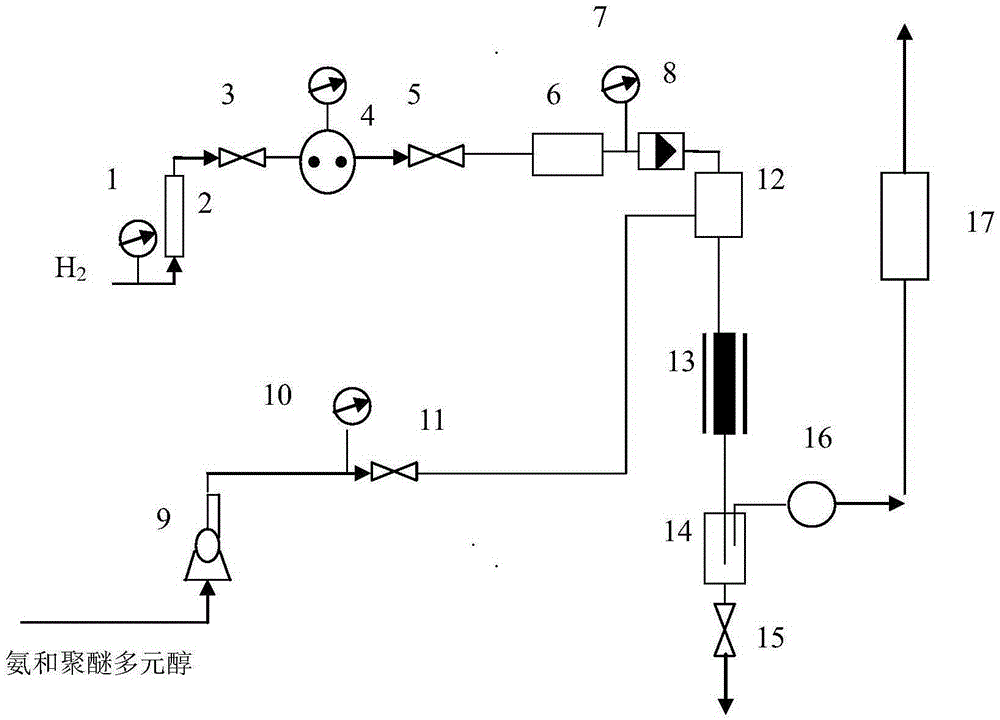

Method used

Image

Examples

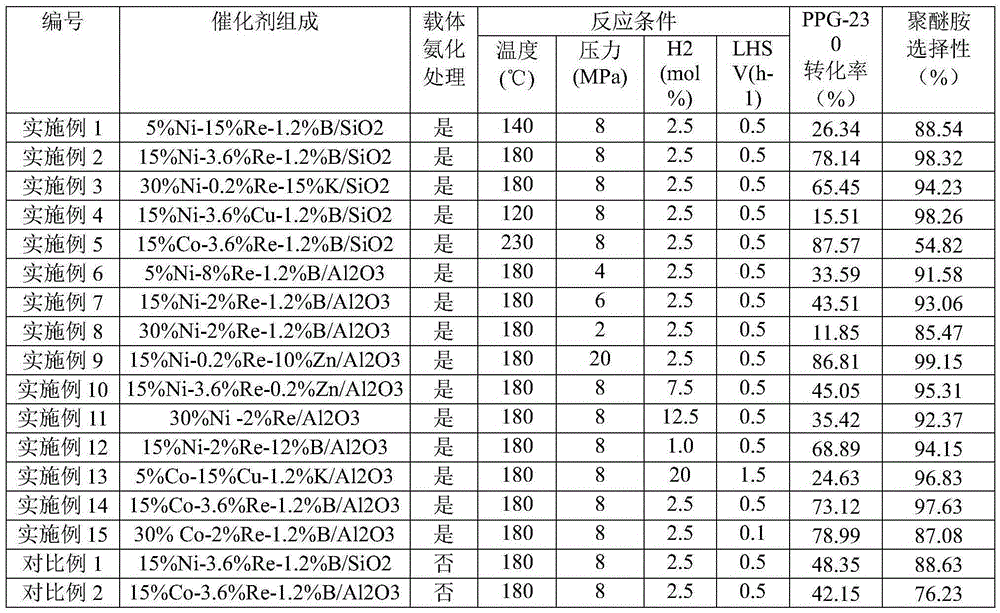

Embodiment 1

[0078] Preparation and Application of 5%Ni-15%Re-1.2%B / SiO2 Catalyst

[0079] Weigh 10 grams of carrier SiO2 (20-40 mesh), put carrier SiO2 in a quartz tube, dry at 200°C for 5 hours under an inert atmosphere, then introduce 10% ammonia-hydrogen gas mixture (molar content), ammoniation temperature The temperature is 300°C, and the ammoniation time is 5 hours. 2.477 g of Ni(NO3)2·6H2O, 2.161 g of NH4ReO4 and 0.686 g of H3BO3 were dissolved in 12 ml of deionized water. Half of this aqueous solution was used to impregnate the above-mentioned ammoniated SiO2 carrier, and then air-dried, then dried at 120° C. for 4 hours, and then calcined at 500° C. for 4 hours. Then, impregnate the ammoniated SiO2 carrier with the other half of the remaining aqueous solution for the second time, then dry it naturally, dry at 120° C. for 4 hours, and bake at 500° C. for 4 hours.

[0080] Weigh 3.2 grams (about 4 ml) of the above-mentioned catalyst and load it into a fixed-bed reactor. The catal...

Embodiment 2

[0082] Preparation and Application of 15%Ni-3.6%Re-1.2%B / SiO2 Catalyst

[0083] Weigh 10 grams of carrier SiO2 (20-40 mesh), put carrier SiO2 in a quartz tube, dry at 200°C for 5 hours under an inert atmosphere, then introduce 20% ammonia-hydrogen gas mixture (molar content), ammoniation temperature The temperature is 300°C, and the ammoniation time is 5 hours. 7.432 grams of Ni(NO3)2·6H2O, 0.518 grams of NH4ReO4 and 0.686 grams of H3BO3 were dissolved in 12 ml of deionized water. Refer to Example 1 for the remaining preparation steps and catalyst evaluation scheme. The reaction conditions and reaction results are shown in Table 1.

Embodiment 3

[0085] Preparation and Application of 30%Ni-0.2%Re-15%K / SiO2 Catalyst

[0086]Weigh 10 grams of carrier SiO2 (20-40 mesh), put carrier SiO2 in a quartz tube, dry at 200°C for 5 hours under an inert atmosphere, then introduce 50% ammonia-hydrogen gas mixture (molar content), ammoniation temperature The temperature is 300°C, and the ammoniation time is 5 hours. 14.864 grams of Ni(NO3)2·6H2O, 0.029 grams of NH4ReO4 and 3.879 grams of KNO3 were dissolved in 12 ml of deionized water. Refer to Example 1 for the remaining preparation steps and catalyst evaluation scheme. The reaction conditions and reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com