Preparation method of yellow complex dye

A complexing and dyeing technology, which is applied in the field of preparation of yellow complexing dyes, can solve problems such as poor solubility, difficult to handle organic matter, and difficult to control the end point, so as to save production costs, reduce environmental burdens, and improve separation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

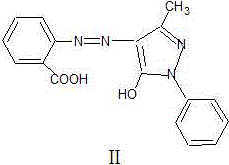

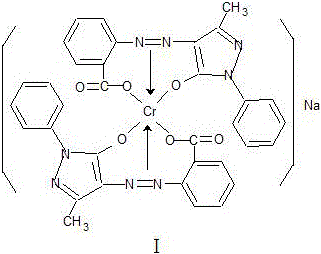

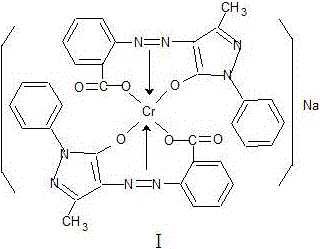

[0017] (1) In the diazo reactor, add 28kg 2-aminobenzoic acid, 60kg hydrochloric acid, 500kg ice water and stir evenly, then add dropwise 55kg of sodium nitrite aqueous solution with a mass concentration of 27%, and react at 10~15°C to obtain a weight Nitrogen solution;

[0018] (2) Add 2000kg of ice water, 37kg of 1-phenyl-3-methyl-5-pyrazolone into the coupling reaction kettle, add 58kg of liquid caustic soda, stir and dissolve completely, and slowly add the above-mentioned Diazo solution, at the same time use liquid caustic soda, control pH = 5.5~6.0, after the reaction reaches the end point, raise the temperature to 70~75°C for crystallization, after the coupling system has gone through the process of changing from thick to thin, keep it warm for another 2 hours, cool down and press the material, Squeeze dry to get coupling filter cake;

[0019] (3) In the chromium salicylate reaction kettle, add 180kg water, 53kg chromium alum, 32kg salicylic acid, after heating up, add ...

Embodiment 2

[0023] (1) In the diazo reactor, add 28kg 2-aminobenzoic acid, 60kg hydrochloric acid, 500kg ice water and stir evenly, then add dropwise 55kg of sodium nitrite aqueous solution with a mass concentration of 27%, and react at 10~15°C to obtain a weight Nitrogen solution;

[0024] (2) Add the above-mentioned diazonium salt into the coupling reaction kettle, add 500kg of ice, and slowly add 1000kg of water, 37kg of 1-phenyl-3-methyl-5-pyrazolone, 58kg of liquid caustic soda Use liquid caustic soda to control the pH=6.0~6.5 of the prepared solution. After the reaction reaches the end point, raise the temperature to 70~75°C for crystallization. Dry to obtain a coupling filter cake;

[0025] (3) In the chromium salicylate reaction kettle, add 180kg water, 53kg chromium alum, 32kg salicylic acid, after heating up, add 75kg liquid caustic soda, filter to obtain chromium salicylate aqueous solution for subsequent use;

[0026] (4) Add the above-mentioned chromium salicylate aqueous s...

Embodiment 3

[0029] (1) In the diazo reactor, add 28kg 2-aminobenzoic acid, 60kg hydrochloric acid, 500kg ice water and stir evenly, then add dropwise 55kg of sodium nitrite aqueous solution with a mass concentration of 27%, and react at 10~15°C to obtain a weight Nitrogen solution;

[0030] (2) Add 2000kg of ice water, 37kg of 1-phenyl-3-methyl-5-pyrazolone into the coupling reaction kettle, add 58kg of liquid caustic soda, stir and dissolve completely, and slowly add the above-mentioned Diazo solution, at the same time use liquid caustic soda, control pH = 5.5~6.0, after the reaction reaches the end point, raise the temperature to 70~75°C for crystallization, after the coupling system has gone through the process of changing from thick to thin, keep it warm for another 2 hours, cool down and press the material, Squeeze dry to get coupling filter cake;

[0031] (3) In the chromium salicylate reaction kettle, add 150kg water, 53kg chromium alum, 4kg salicylic acid, a batch of recycled sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com