Foaming asphalt system, and preparation device, preparation and usage methods of foaming asphalt

A technology of foamed asphalt and preparation equipment, which is applied in the direction of climate change adaptation, roads, road repairs, etc. It can solve problems such as inconvenient use, increase the workload of mixing plants, and limit the application range of foamed asphalt, so as to ensure stability, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

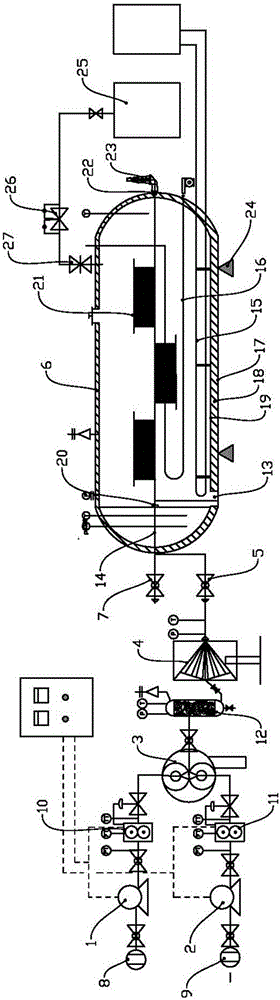

[0026] The foamed asphalt preparation device of this embodiment comprises the asphalt pump 1 and foaming agent pump 2 that are respectively connected to the asphalt feeding system and foaming agent feeding system, and the discharge pipelines of the asphalt pump and foaming agent pump are all connected to Mixer 3, the outlet of said mixer is connected to the inlet and outlet pipeline 14 of a pressure tank 6 through pressurization equipment 4 (air ejector) and pressure tank feed valve 5; The inlet and outlet pipeline of pressure tank 6 is also passed pressure The tank discharge valve 7 is connected to the discharge pipe; the device also includes a pressure tank heating system capable of heating the material in the pressure tank, and a pressure tank pressure stabilization system capable of maintaining a certain pressure higher than normal pressure in the pressure tank, and A stirring system capable of stirring the materials in the pressure tank. An asphalt heating device 8 and a ...

Embodiment 2

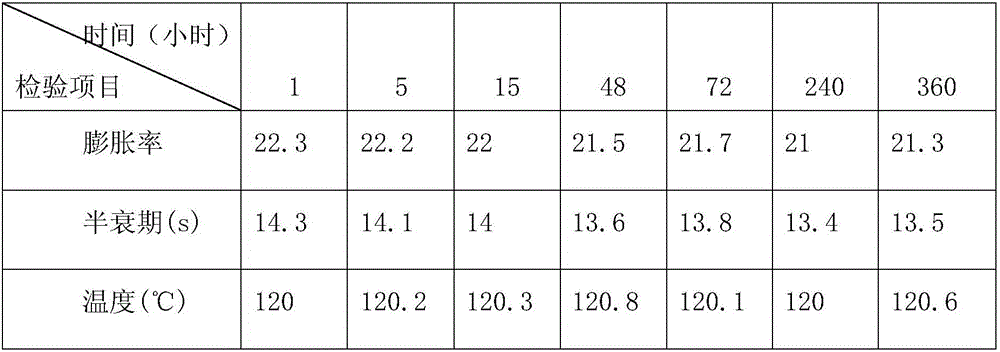

[0035] Utilize the device and method of the present invention to produce 20 tons of foamed asphalt, store for 1 hour, 5 hours, 15 hours, 48 hours, 72 hours, 240 hours, and test indicators after 360 hours.

[0036] Process conditions:

[0037] Raw asphalt: AH-70# asphalt; temperature 120°C

[0038] Foaming agent is normal temperature water.

[0039] The ratio of raw material asphalt and water is 98%: 2% by mass ratio;

[0040] Production capacity: 10 tons / hour

[0041] The method for implementing this embodiment includes the following steps:

[0042] Step 1: Preheat the system, start the asphalt pump, and circulate the raw asphalt through the heat exchanger and flow meter to preheat the temperature to 130±0.5°C. The ratio of raw asphalt to foaming agent (water) is 98%:2%. It is 9.8 tons / hour to set and adjust the bitumen flow rate; Start the blowing agent pump, be 98%: 2% according to the ratio of raw material bitumen and blowing agent (water), set the flow rate of blowin...

Embodiment 3

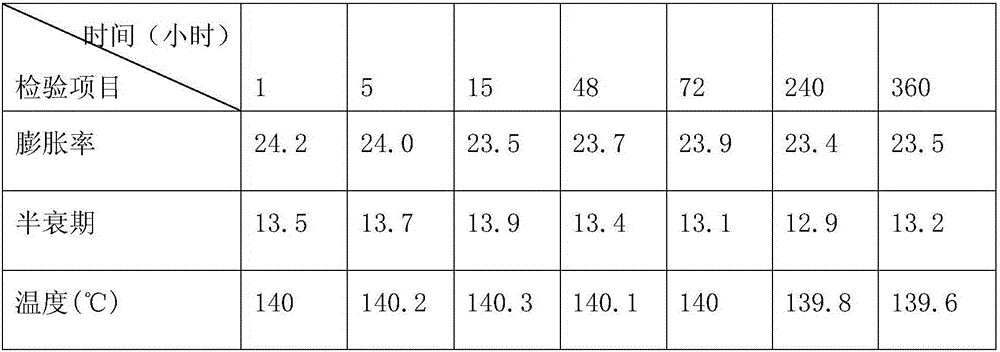

[0053] Utilize the device and method of the present invention to produce 60 tons of foamed asphalt, store for 1 hour, 5 hours, 15 hours, 48 hours, 72 hours, 240 hours, and test indicators after 360 hours.

[0054] Process conditions:

[0055] Raw asphalt: SBS modified asphalt I-C; temperature 140°C

[0056] Foaming agent is normal temperature water.

[0057] The ratio of raw material pitch to water is 97.5% by mass: 2.5%;

[0058] Production capacity: 20 tons / hour

[0059] The method for implementing this embodiment includes the following steps:

[0060] Step 1: Preheat the system, start the asphalt pump, and circulate the raw asphalt through a heat exchanger and a flow meter to preheat the temperature to 140±0.5°C. The ratio of raw asphalt to foaming agent (water) is 97.5%:2.5%. It is 19.5 tons / hour to set and adjust the bitumen flow rate; Start the blowing agent pump, be 97.5%: 2.5% according to the ratio of raw material bitumen and blowing agent (water), set the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com