Preparation method of adhesive type building external thermal insulation composite decorative plate

A technology for external thermal insulation and decorative panels, which is applied to ceramic products, applications, household appliances, etc., can solve the problems of thermal insulation composite decorative panels that need to be improved, complex processes, etc., to achieve easy implementation and control, short technical processes, and reduce logistics and transportation and storage cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

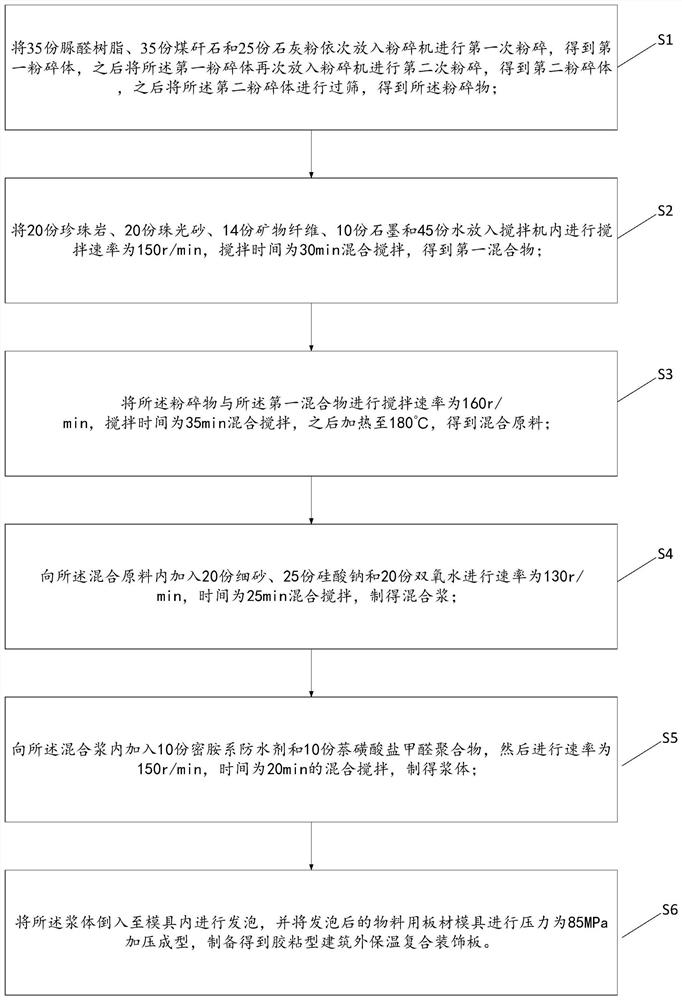

[0031] The present invention provides a kind of preparation method of adhesive type building external thermal insulation composite decorative board, comprising the following steps:

[0032] In terms of parts by mass, 30-40 parts of resin, 30-40 parts of coal gangue and 20-30 parts of lime powder are put into a pulverizer to pulverize to obtain a pulverized product;

[0033] 15-25 parts of perlite, 15-25 parts of pearl sand, 12-18 parts of inorganic fiber, 8-12 parts of modified additives and 40-50 parts of water are put into a mixer and mixed to obtain the first mixture;

[0034] mixing and stirring the pulverized material and the first mixture, and then heating to a preset temperature to obtain a mixed raw material;

[0035] Add 15-25 parts of fine sand, 20-30 parts of sodium silicate and 15-25 parts of foaming agent into the mixed raw material and mix and stir to prepare a mixed slurry;

[0036] Adding 8-12 parts of waterproofing agent and 8-12 parts of surfactant to the mi...

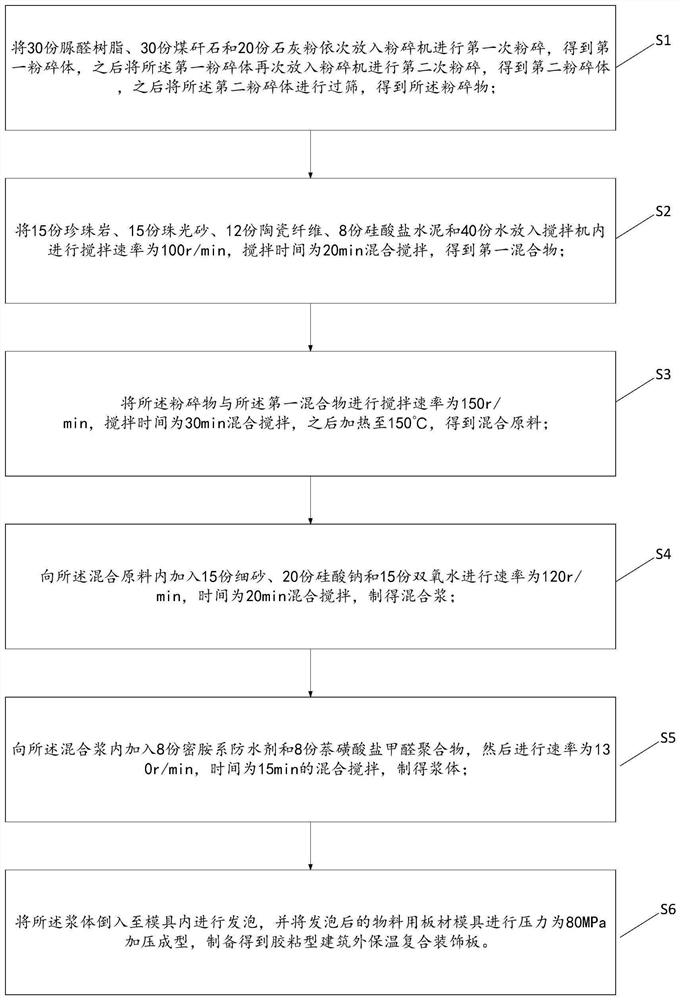

Embodiment 1

[0057] Example 1, see figure 1 , the present invention proposes a kind of preparation method of adhesive type building external thermal insulation composite decorative board, comprises the following steps:

[0058]S1: Put 30 parts of urea-formaldehyde resin, 30 parts of coal gangue and 20 parts of lime powder into the pulverizer in turn for the first pulverization to obtain the first pulverized body, and then put the first pulverized body into the pulverizer again for the second pulverization. secondary crushing to obtain a second crushed body, and then sieve the second crushed body to obtain the crushed body;

[0059] S2: Put 15 parts of perlite, 15 parts of pearl sand, 12 parts of ceramic fiber, 8 parts of Portland cement and 40 parts of water into the mixer and mix and stir at a speed of 100 r / min for 20 minutes to obtain the first mixture;

[0060] S3: Mix and stir the pulverized material and the first mixture at a rate of 150 r / min for 30 minutes, and then heat to 150° ...

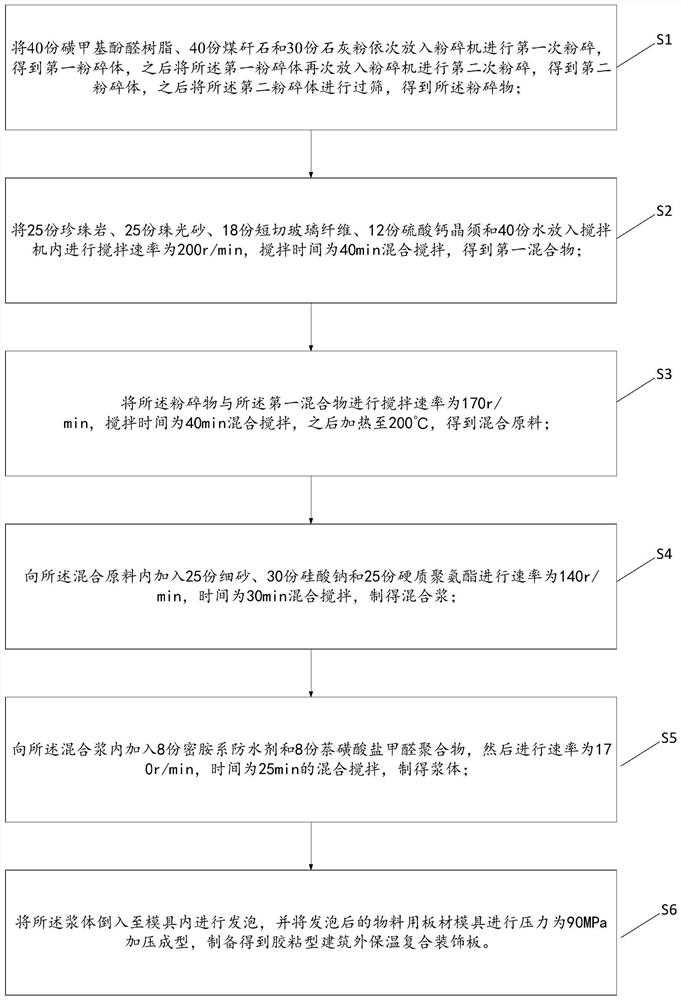

Embodiment 2

[0064] Example 2, see figure 2 , the present invention proposes a kind of preparation method of adhesive type building external thermal insulation composite decorative board, comprises the following steps:

[0065] S1: Put 40 parts of sulfomethyl phenolic resin, 40 parts of coal gangue and 30 parts of lime powder into the pulverizer in turn for the first pulverization to obtain the first pulverized body, and then put the first pulverized body into the pulverizer again performing a second pulverization to obtain a second pulverized body, and then sieving the second pulverized body to obtain the pulverized product;

[0066] S2: Put 25 parts of perlite, 25 parts of pearl sand, 18 parts of chopped glass fiber, 12 parts of calcium sulfate whiskers and 40 parts of water into the mixer and stir at a stirring rate of 200 r / min for 40 minutes to obtain the first mixture;

[0067] S3: Stir the ground material and the first mixture at a rate of 170 r / min for 40 min, and then heat to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com