Ferrite bead and preparation method thereof

A ferrite bead and ferrite material technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, inductors, etc., can solve problems such as product short circuit, poor appearance of magnetic bead products, and low production efficiency. Effects of improved appearance, low processing cost, and high appearance pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the ferrite bead of this specific embodiment comprises the following steps:

[0022] S1, preparing a semi-finished ferrite bead, in which a magnet is sintered from a ferrite material, and a silver electrode is arranged on the magnet.

[0023] S2, putting the ferrite bead semi-finished product into a furnace with an oxygen volume fraction of 60%-95% for high-temperature treatment at a temperature of 400°C-600°C for 2h-10h, and cooling in the furnace after the treatment.

[0024] Based on the ferrite material, there may be a problem of incomplete sintering during the sintering process, resulting in metal particles on the surface of the magnet, and then the surface material is improved through the high-temperature furnace treatment process in step S2. The conversion efficiency of the metal particles on the surface of the magnet in the semi-finished magnetic beads into metal oxides is low. When the oxygen atmosphere is added when returning to the f...

experiment example 1

[0034] Prepare the semi-finished ferrite bead, and spread the semi-finished product on the silicon carbide saggar. Put the semi-finished silicon carbide sagger into the bell furnace. After sealing, vacuumize the furnace so that the pressure in the furnace is -50KPa, and then fill the gas with an oxygen content of 60%. After the oxygen is introduced, the pressure in the furnace is maintained at 2Kpa. Start the heating program, heat to 400°C within 1h, and then heat treat at this temperature for 2h. After the treatment, cool down with the furnace. Electroplating is carried out on the processed magnetic bead semi-finished product, and a metal plating layer is deposited on the electrode of the magnetic bead semi-finished product to obtain a ferrite magnetic bead.

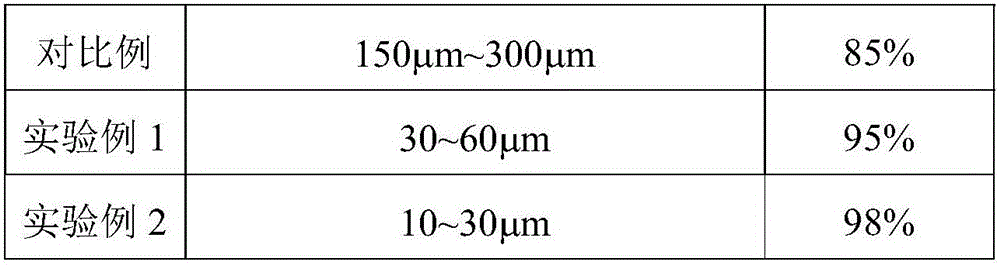

[0035] Test the appearance effect and appearance qualification rate of the same batch of ferrite beads produced, and the test results are shown in the table below.

experiment example 2

[0037] Prepare ferrite bead semi-finished products, and place the semi-finished products on the anti-mouth bowl made of alumina in a stacked and superimposed manner. Put the semi-finished aluminum oxide anti-bowl into the bell furnace. After sealing, vacuumize the pressure in the furnace to -120KPa, then fill in the gas with an oxygen content of 95%, and make the pressure in the furnace Keep it at 5KPa. Start the heating program, heat to 600°C within 2h, and then heat treat at this temperature for 10h. After heat treatment, cool down with the furnace. Electroplating is carried out on the processed magnetic bead semi-finished product, and a metal plating layer is deposited on the electrode of the magnetic bead semi-finished product to obtain a ferrite magnetic bead.

[0038] Test the appearance effect and appearance qualification rate of the same batch of ferrite beads produced, and the test results are shown in the table below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com