Method for controlling risks of lithium-ion battery thermal runaway

A lithium-ion battery and a control method technology are applied in the field of control of the risk of thermal runaway of lithium-ion batteries, and can solve the problem that the physical, chemical, and thermal properties of the battery cannot be comprehensively considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

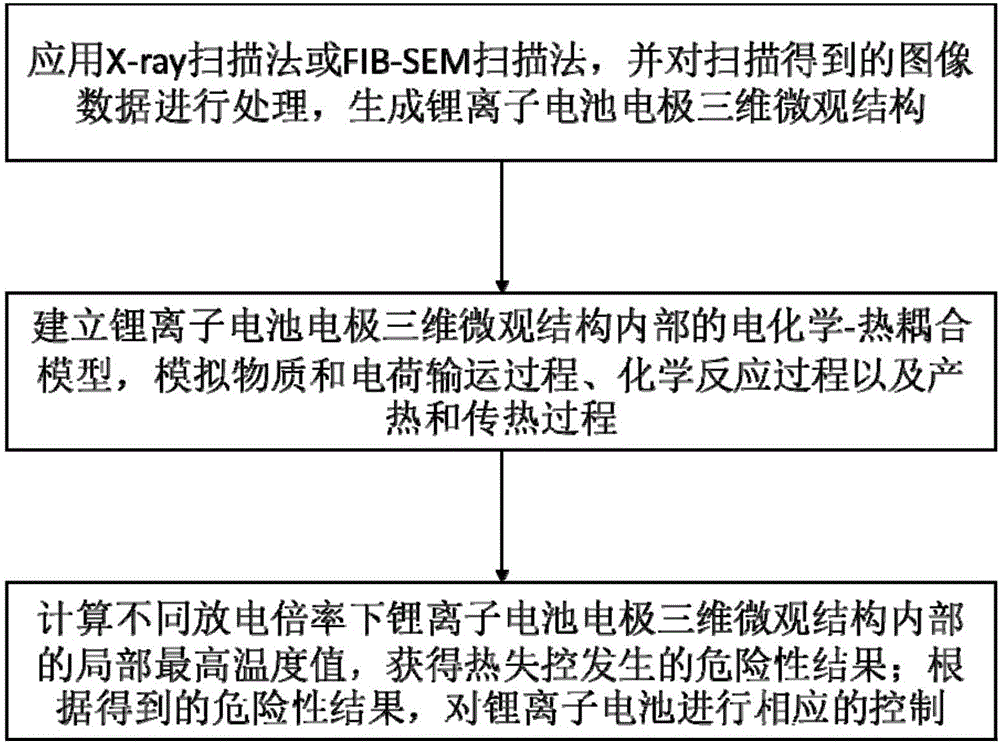

[0056] like figure 1 As shown, the present invention provides a method for controlling the risk of thermal runaway of a lithium-ion battery, which includes the following steps:

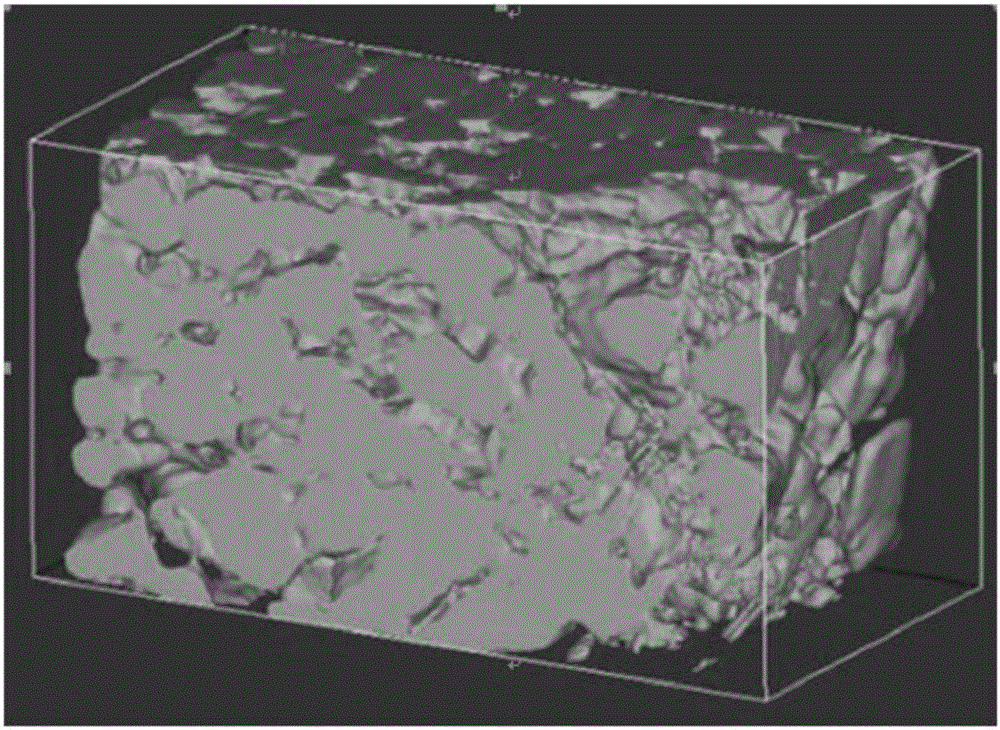

[0057] S1: Apply X-ray scanning method or FIB-SEM scanning method, and process the scanned image data to generate a three-dimensional microstructure of lithium-ion battery electrodes;

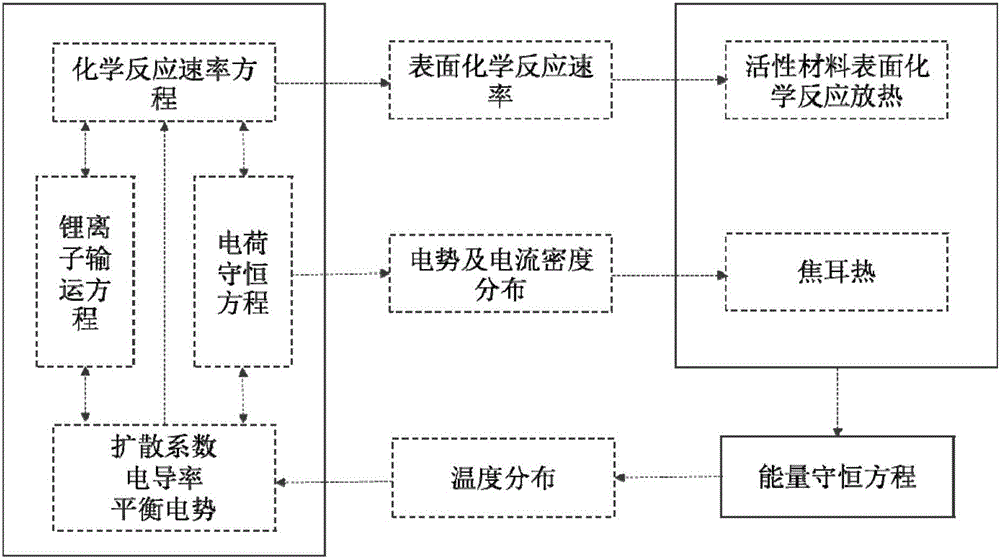

[0058] S2: Establish an electrochemical-thermal coupling model inside the three-dimensional microstructure of lithium-ion battery electrodes, which is used to simulate the material and charge transport process, chemical reaction process, and heat generation and heat transfer process; the electrochemical-thermal coupling model mainly includes The governing equation of lithium ion tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com