Electromagnetic heating type enzyme deactivating machine

A heating and greening machine technology, applied in the direction of tea processing before extraction, can solve the problems of temperature control lag, difficult temperature control, pollution, etc., and achieve the effects of fast heating and cooling, easy temperature control, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

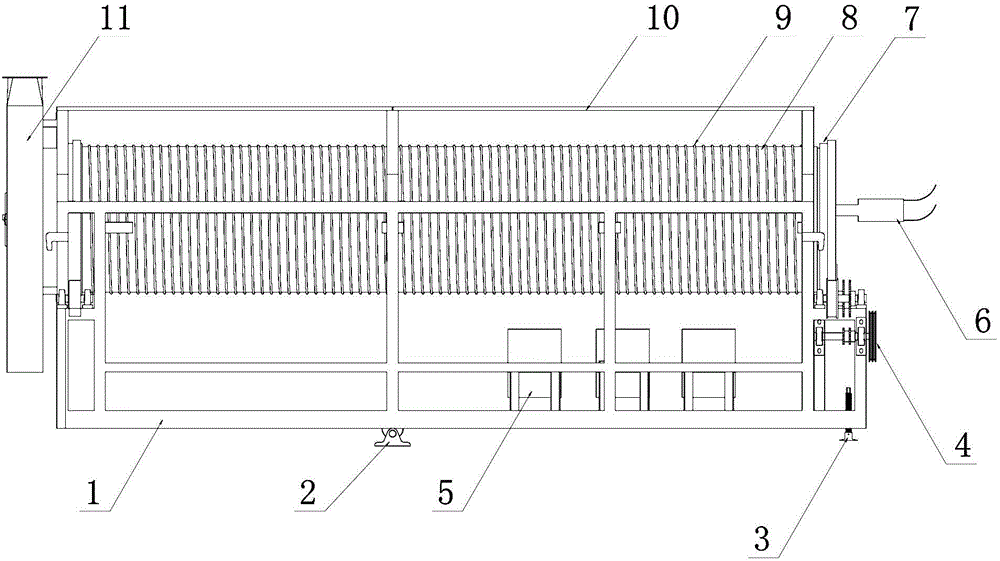

[0022] Such as figure 1 , 2 Among them, an electromagnetic heating type greening machine includes a frame 1, a greening tube 7 is rotatably supported on the frame 1, one end of the greening tube 7 is connected to a driving device, and the other end is connected to an exhaust pipe 11, and the driving device The cylinder 7 is driven to rotate, and the water vapor produced by finishing is discharged from the exhaust pipe 11.

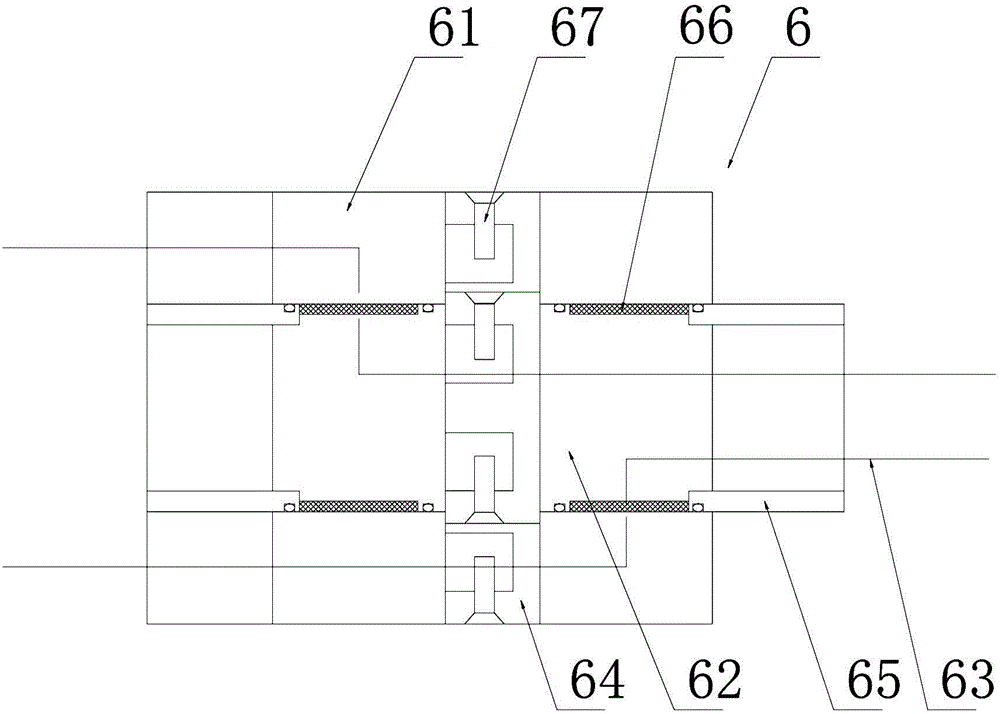

[0023] The outer wall of the killing cylinder 7 is provided with a thermal insulation layer 8, and at least one group of coils 9 are wound outside the thermal insulation layer 8, and the coils 9 are connected with the electromagnetic generator 5 through the sliding conductive ring 6; the electromagnetic generator 5 generates 20-45KHz The high-frequency current is sent to the coil 9 through the sliding conductive ring 6, and an eddy current is generated on the surface of the fixing tube 7, so that the fixing tube 7 generates heat by itself, and the finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com