Method for preparing tobacco flavor precursor by cysteine tracing method in aqueous phase and its products and applications

A technology for cysteine and tobacco flavors, which is applied in the field of preparation of tobacco flavor precursors by cysteine tracer method in water phase, can solve the problem of difficult capture of reaction intermediates, achieve reduced production costs and simple operation , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

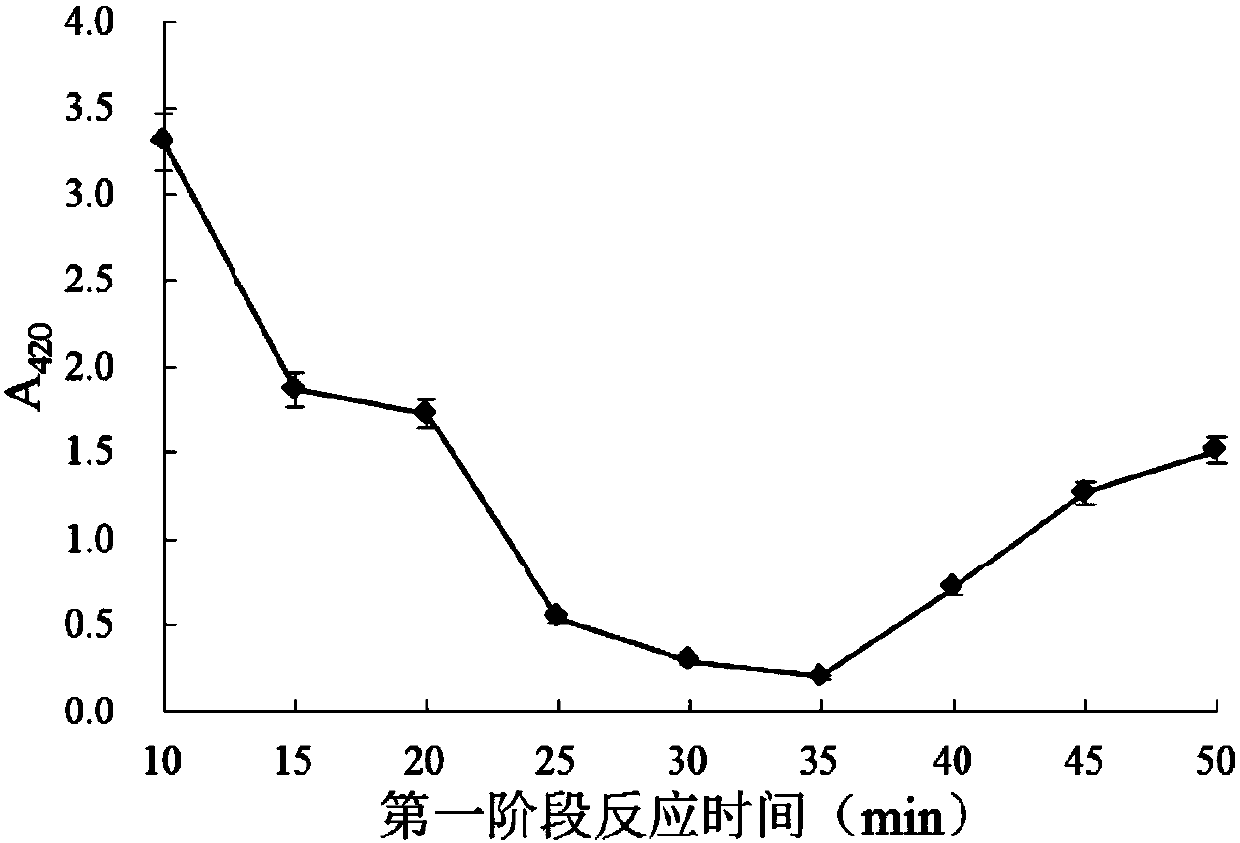

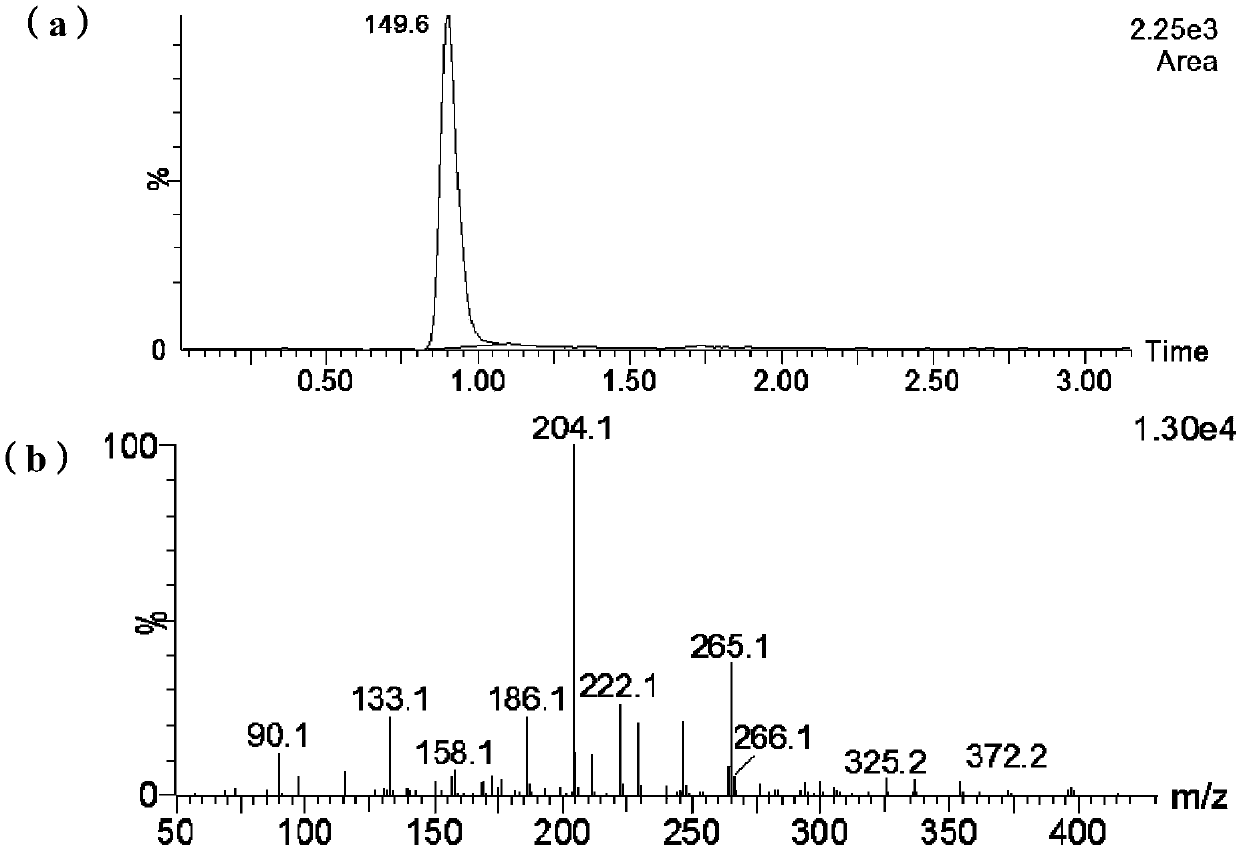

[0028] Dissolve 5kg of alanine and 10kg of xylulose in 500kg of water, adjust the pH of the mixed solution to 7.5, and perform a low-temperature Maillard reaction at 70°C. The following steps are used to determine the optimum reaction time under the above conditions:

[0029] (1) Dissolve alanine and xylulose in water according to the above ratio, adjust the pH of the mixed solution to 7.5, divide the solution into 9 parts on average, pour them into Maillard reaction bottles respectively, and heat at 70°C for the second The first-stage low-temperature Maillard reaction was terminated by cooling in an ice bath after 10, 15, 20, 25, 30, 35, 40, 45 and 50 min, respectively;

[0030] (2) Add 0.6 kg of cysteine to each part of the reaction solution obtained in step (1) respectively, and adjust the pH of the reaction solution to 7.5, and then heat up to 120° C. to carry out the second-stage high-temperature Maillard reaction for 120 min. Cooling in an ice bath terminates the react...

Embodiment 2

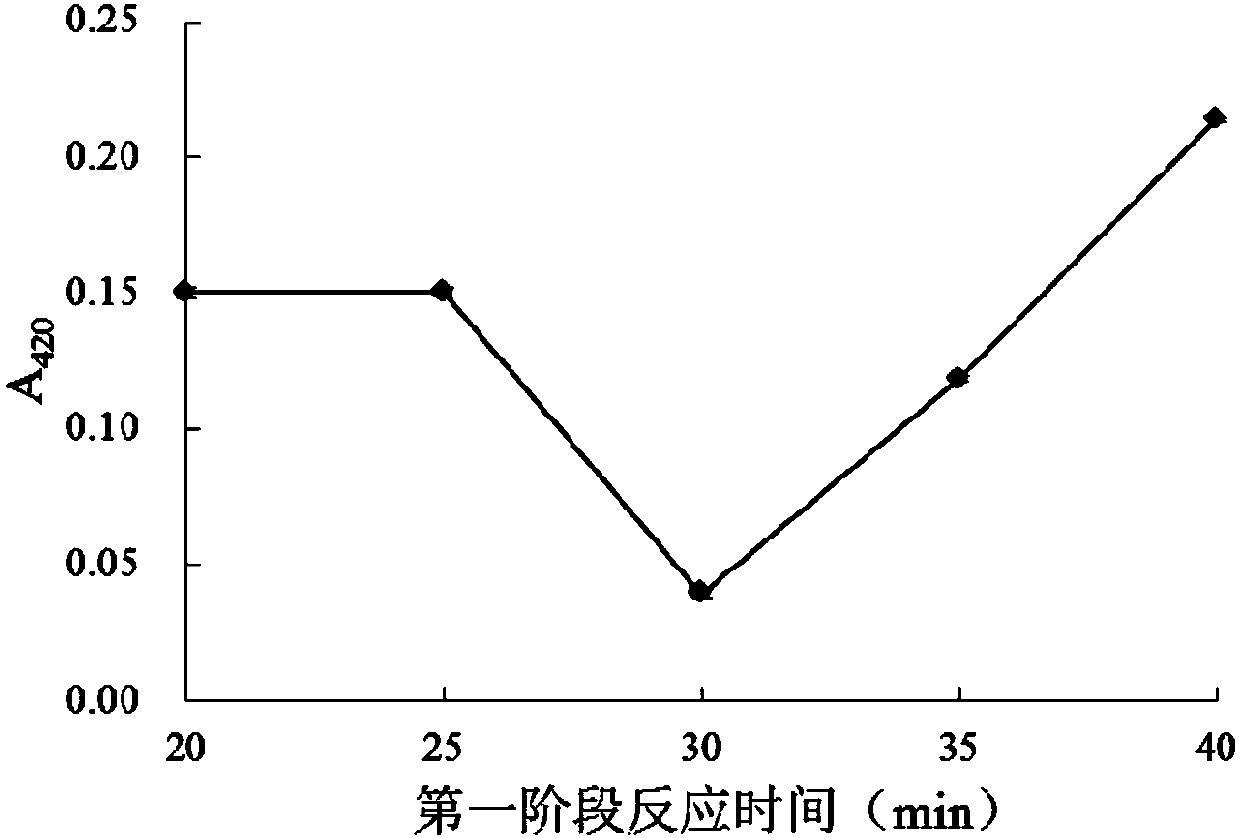

[0035] Dissolve 20kg of aspartic acid and 60kg of xylulose in 800kg of water, adjust the pH of the mixed solution to 8.0, and heat at 120°C to generate a Maillard reaction. The following steps are used to determine the optimum reaction time under the above conditions:

[0036] (1) Dissolve alanine and xylulose in water according to the above ratio, adjust the pH of the mixed solution to 8.0, divide the solution into 5 parts on average, pour them into Maillard reaction flasks respectively, and heat at 120°C for the second step. The first-stage low-temperature Maillard reaction was terminated by cooling in an ice bath after 20, 25, 30, 35 and 40 min, respectively;

[0037] (2) Add 2.0kg of cysteine to each part of the reaction solution obtained in step (1) respectively, and adjust the pH of the reaction solution to 8.0, then heat up to 150°C for the second stage of high-temperature Maillard reaction for 200min, using Cooling in an ice bath terminates the reaction to obtain a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com