Copper-lead separation flotation inhibitor and applications thereof

A copper-lead separation and inhibitor technology is applied in the separation of copper sulfide and lead sulfide minerals, mineral processing, and complex copper-lead-zinc beneficiation and separation. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

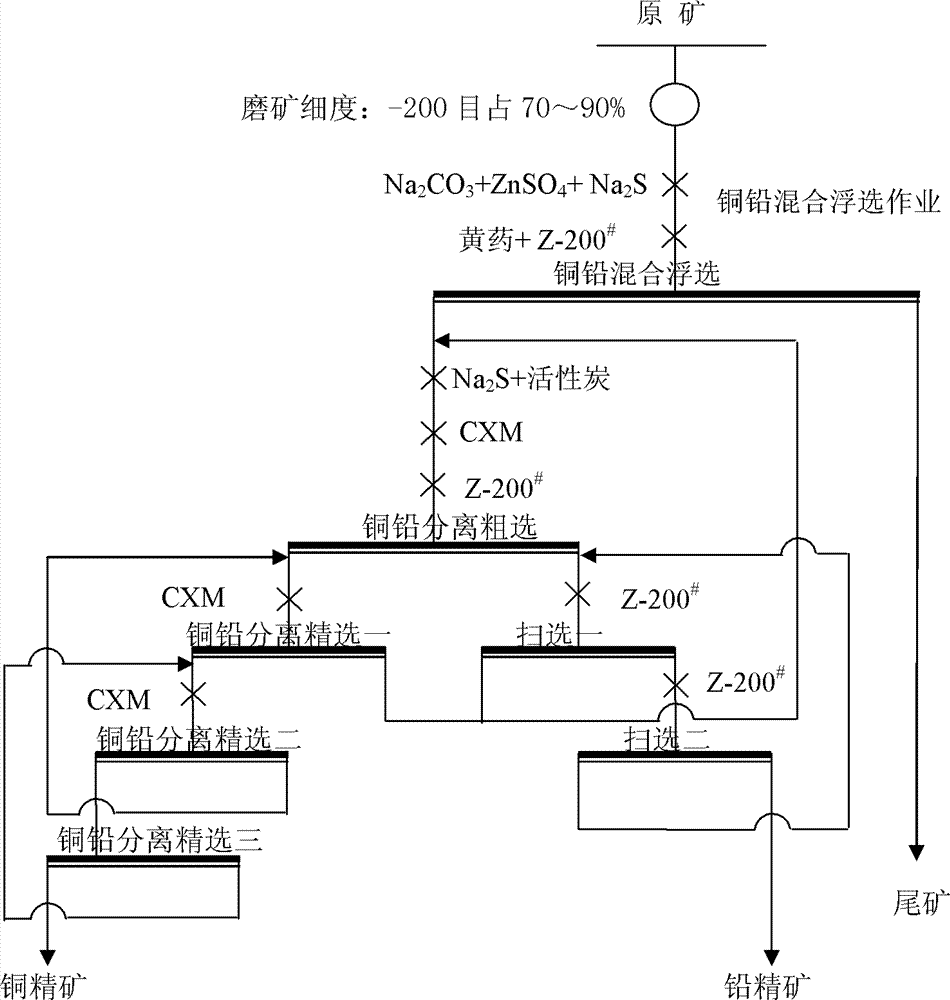

[0033] The copper mineral in a complex lead-zinc mine in Jiangxi is recovered by the present invention as raw ore. The raw ore contains 0.30-0.80% copper, 2.00-4.50% lead, and 3.00-6.50% zinc. The raw ore has complex properties and various useful minerals are embedded. The particle size is uneven, and some minerals are distributed in fine particles. The symbiosis relationship between copper minerals and lead minerals is complex, the particle size of the distribution is fine, the lead minerals have very good buoyancy, and the separation of copper and lead minerals is very difficult.

[0034] (1) The raw ore adopts the process of mixed flotation and separation to select copper and lead minerals; the raw ore is ground to -200 mesh, accounting for 82.15%, and then 600 g / t of sodium carbonate, 600 g / t of zinc sulfate and 200 g / t of sulfide are added Sodium as an inhibitor, 10 g / t xanthate and 30 g / t Z-200 # As a collector for copper-lead mixed flotation operations.

[0035] (2) Co...

Embodiment 2

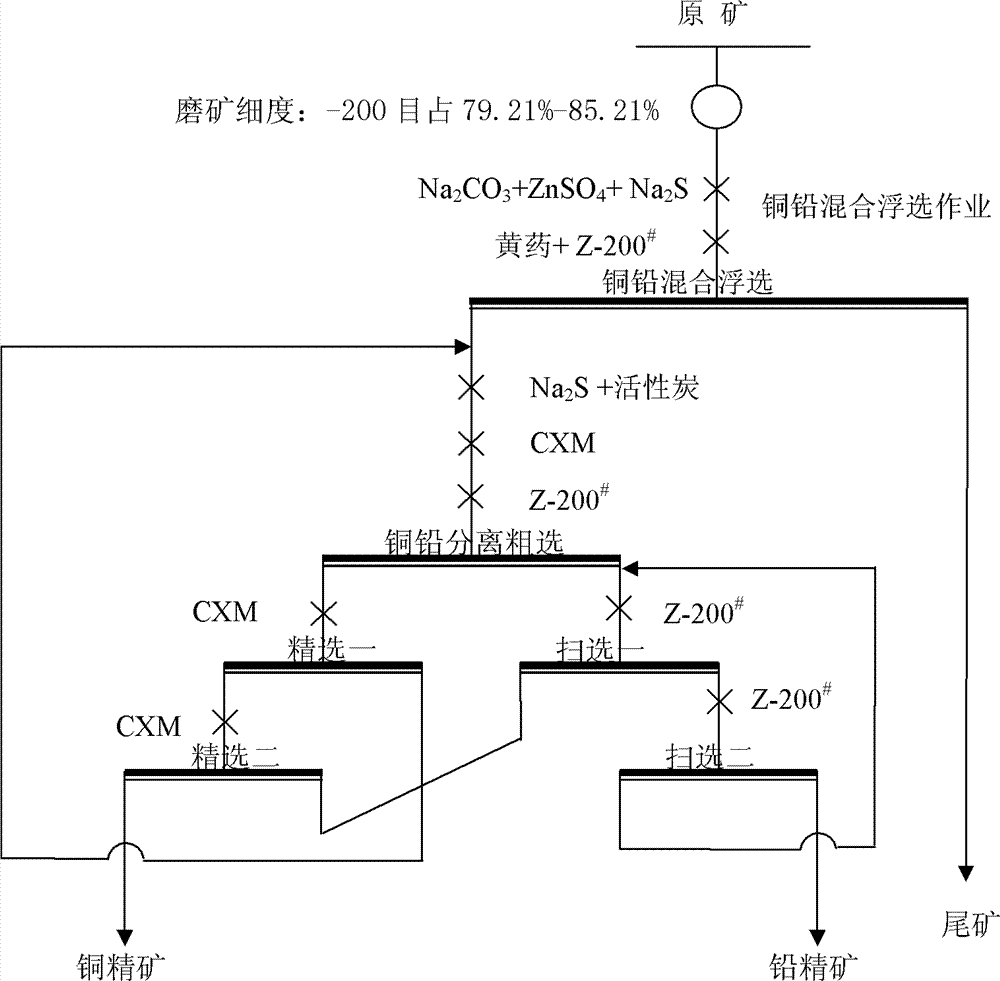

[0042] A complex copper-lead-zinc mine in Qinghai is used as raw ore. The raw ore contains 0.60-1.00% copper, 2.80-5.00% lead, and 4.00-6.80% zinc. The mosaic relationship between copper, lead and zinc minerals in the ore is complex, and the mosaic particle size is extremely fine. First adopt copper-lead mixed flotation to obtain copper-lead mixed concentrate (same as embodiment 1), and then carry out copper-lead separation operation.

[0043] The specific copper-lead separation process is shown in the appendix figure 2 , The copper-lead separation operation adopts one roughing, two selections, and one sweeping operation. For the obtained copper-lead mixed concentrate, first add 300 g / t activated carbon and 1200 g / t sodium sulfide, stir for 6 minutes, then add 150 g / t CXM, stir for 5 minutes, then add 15 g / t Z-200 # , after stirring for 2 minutes, carry out the copper-lead separation roughing operation; after the roughing operation, carry out two beneficiation operations to...

Embodiment 3

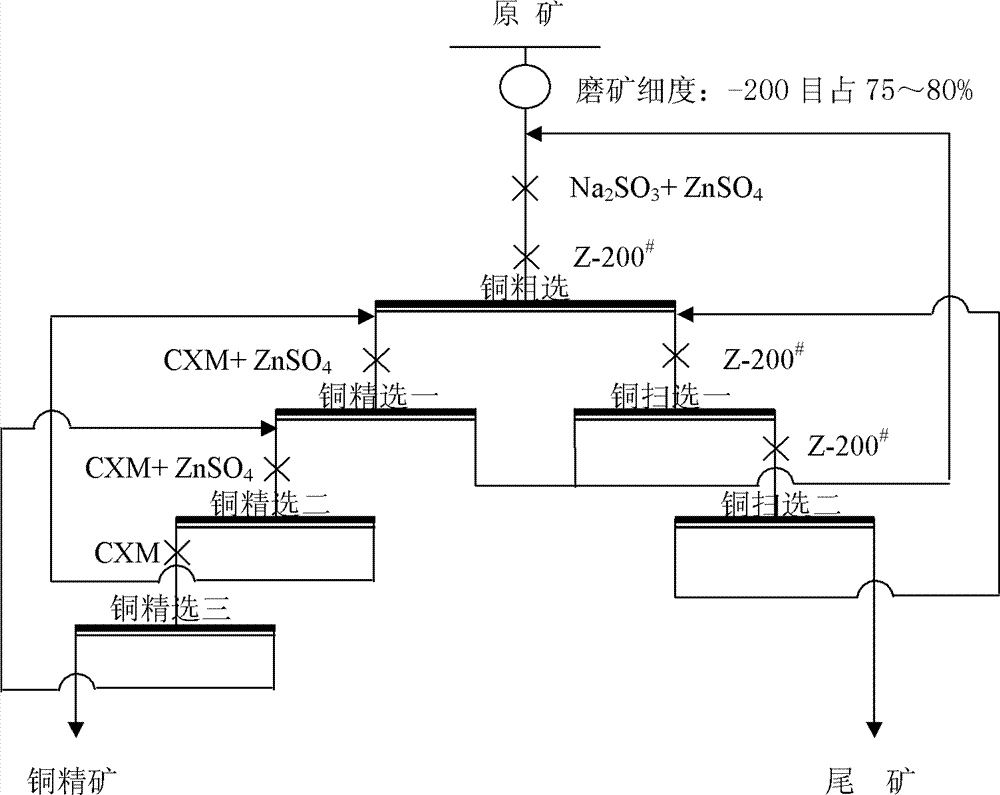

[0049] A complex copper-lead-zinc sulfide ore in Gansu is used as the raw ore. The raw ore contains 0.36-0.59% copper, 1.82-3.21% lead, and 2.00-4.50% zinc. The main copper sulfide mineral in the ore is tetrahedrite, followed by chalcopyrite, and the ore-forming tetrahedrite is replaced by pyrite, arsenopyrite, pyrrhotite, sphalerite, and galena in multiple stages. Segmentation, wrapping, and erosion make it very complex in structure. Chalcopyrite is distributed in the gangue in the form of intermittent raindrops, and its nature is relatively simple.

[0050] Raw ore adopts the priority flotation process of roughing, three-selecting and two-sweeping to select copper. For the specific separation process of copper and lead, see the attached image 3 , rough selection with 1000 g / ton sodium sulfite, 1000 g / ton zinc sulfate, 60 g / ton Z-200 # As a collector, selection 1 adds 150 g / t CXM and 400 g / t zinc sulfate as inhibitors; selection 2 adds 75 g / t CXM and 200 g / t zinc sulfate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com