Method for preparing freeze-dried preparation in any shape and product thereof

A freeze-dried preparation and a technology of any shape, which is applied in the field of preparing freeze-dried preparations of any shape and their products, and can solve the problems of no demoulding, single preparation shape, single shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A. Prepare a solution by mixing 1 liter of water, 200 g of VC powder, and 40 g of pullulan to form liquid 1;

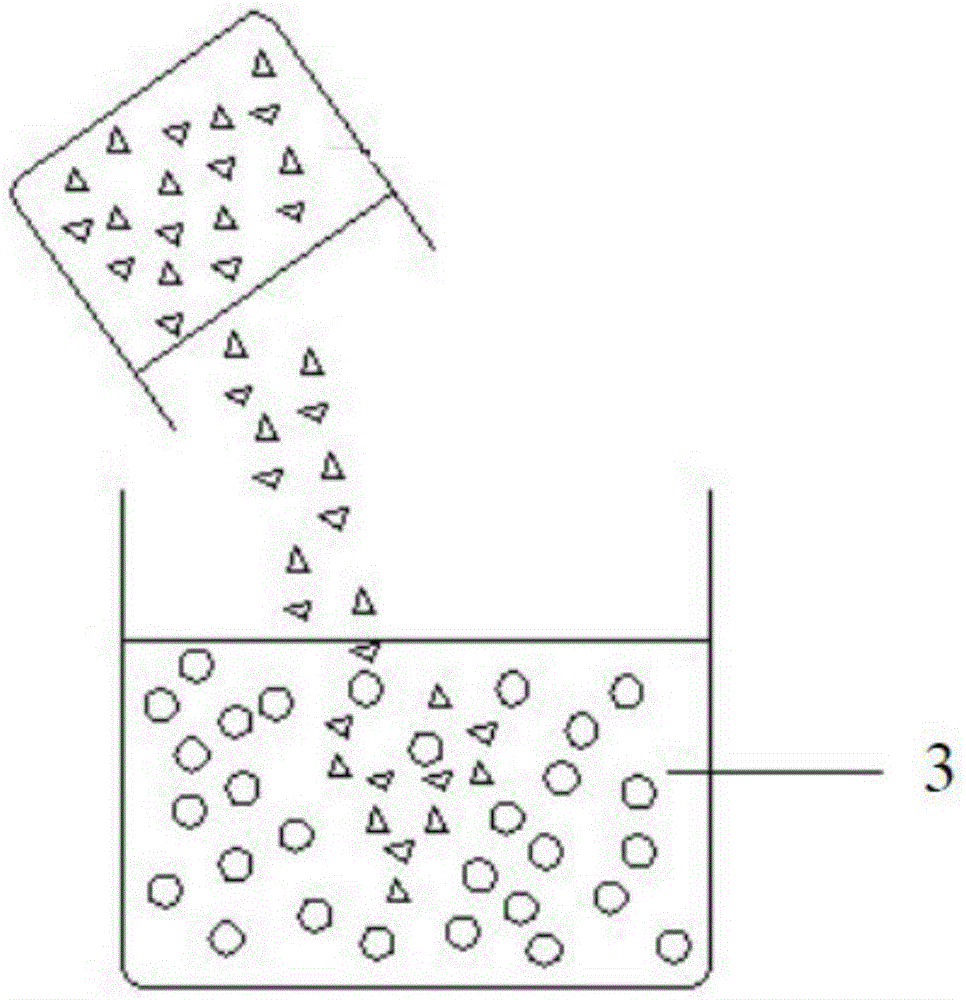

[0077] B. Freeze liquid 1, and spray it with liquid nitrogen during the freezing process to form snowflake-like ice powder, which is component 2;

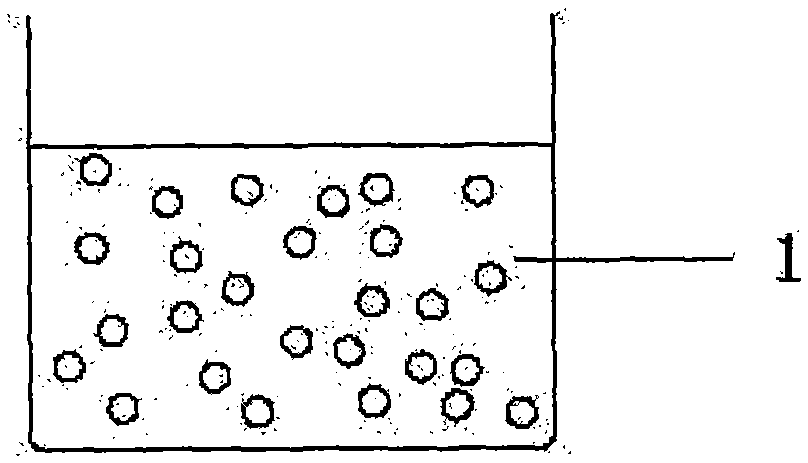

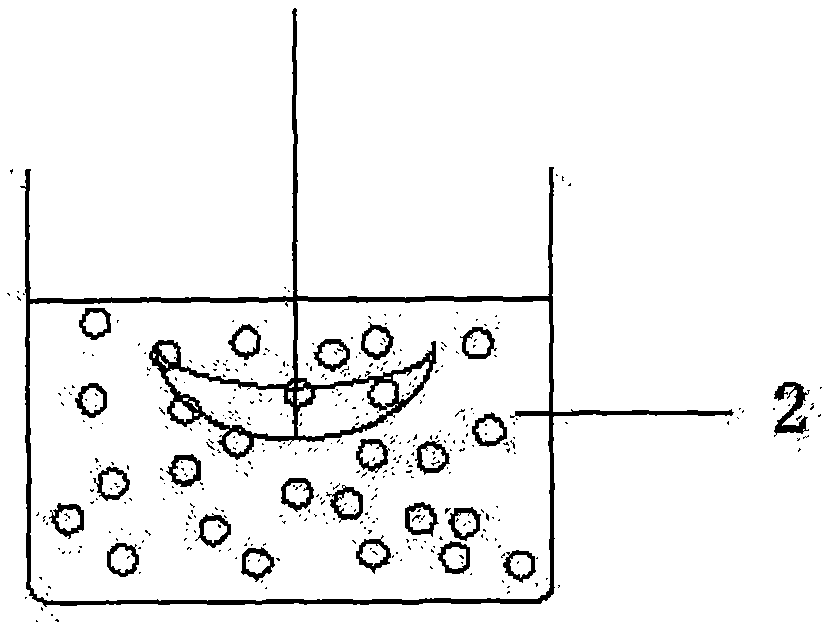

[0078] C. Put component 2 into a cylindrical mold for quantification to form quantitative component 4, and apply a certain pressure to press into component 4;

[0079] D. Freeze-dry the compressed component 4 to form freeze-dried VC essence powder for external use 12 .

Embodiment 2

[0081] A. Add 1 liter of VE 100g, Tween 30g, mannitol 50g, carbomer 30g, and triethanolamine 50ml to form an emulsion to form liquid 1;

[0082] B. Freeze liquid 1, and during the freezing process, spray it with liquid nitrogen to form ice crystals, and further enter the low-temperature pulverizer for crushing until it passes through a 200-mesh sieve, which is component 2;

[0083] C. Put component 2 into an ellipsoidal mold for quantification to form quantitative component 4, and apply a certain pressure to press into component 4;

[0084] D. Freeze-dry the compressed component 4 to form a freeze-dried VE milk solid ointment 12 .

Embodiment 3

[0086] A. Add 200g of nano-grade pearl powder and 30g of xanthan gum to 1 liter of water to make a suspension, and disperse evenly to form liquid 1;

[0087] B. Freeze liquid 1, and after freezing, use a low-temperature pulverizer to physically crush it to form ice particles, which is component 2;

[0088] C, component 2 is packed into hemispherical mold quantitatively, forms quantitative component 4;

[0089] D. Freeze-dry component 4 to form a freeze-dried oral pearl powder health food.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com