Catalyst heavy metal cycle pollution ageing reactor

A reactor and catalyst technology, applied in the field of reactors, can solve the problems of long aging treatment time and large amount of water vapor in the aging reactor, and achieve the effects of long treatment time, simple structure and large amount of water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This example is used to illustrate the catalyst heavy metal cyclic pollution aging reactor provided by the present invention and its application.

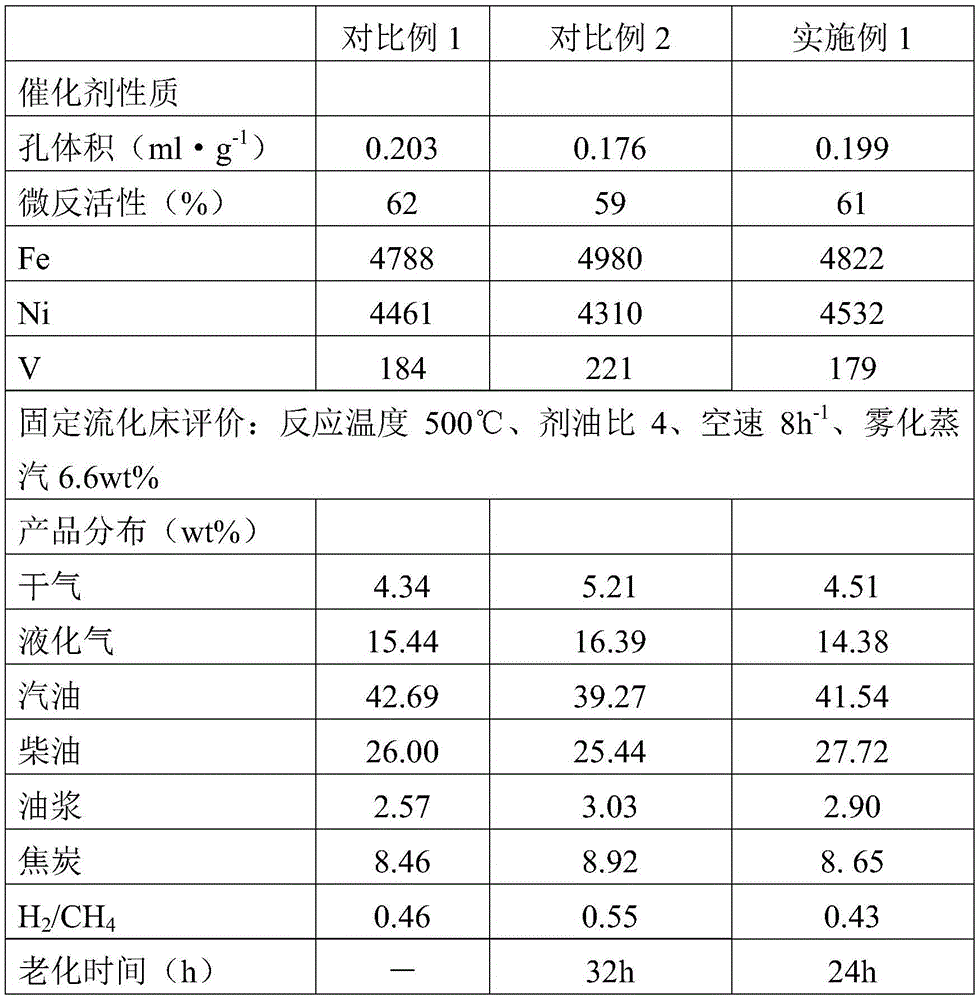

[0075] The feedstock oil used in this example is Daqing straight-run diesel fuel added with nickel naphthenate, vanadium naphthenate and iron naphthenate. In this diesel feedstock, the content of nickel is 600ppm, the content of vanadium is 500ppm, and the content of iron is 500ppm. The experimental device used is the heavy metal cyclic pollution aging reactor device described in the present invention.

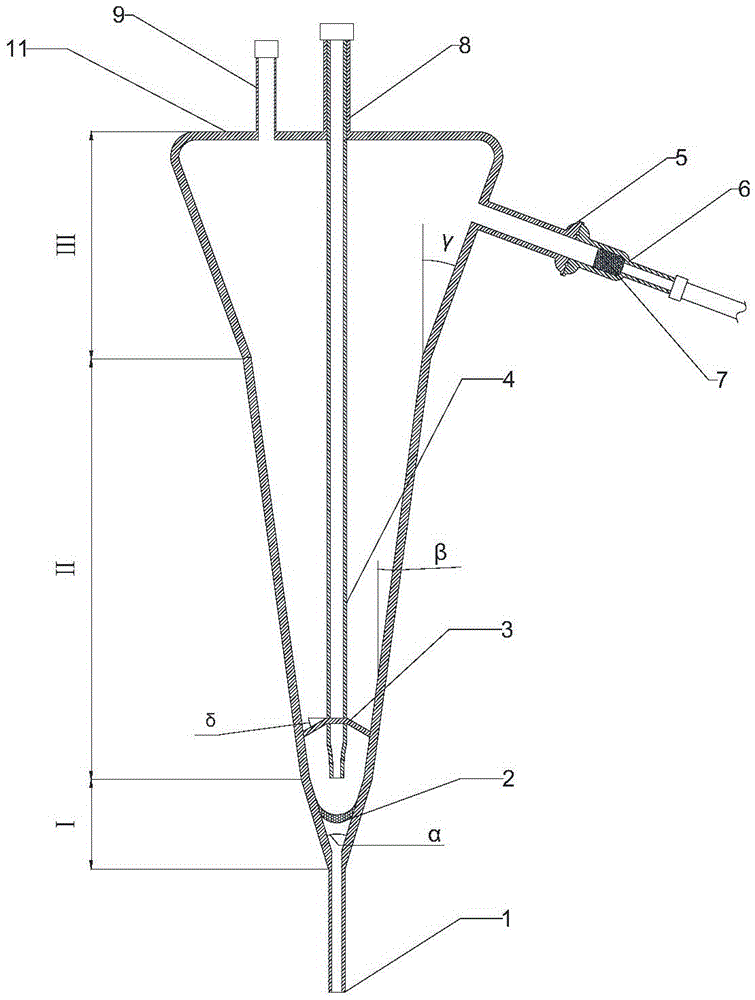

[0076] according to figure 1 The shown catalyst heavy metal cyclic pollution aging reactor, the reactor body 11 includes a sedimentation section III, an aging section II, and a pre-distribution section I from top to bottom. The cross-sectional area of the reactor body 11 gradually decreases from top to bottom. , The cross-sectional area of the lower end of the settlement section III is equal to the cross-sectional area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com