Protein type halogen resistant combustible gas combustion catalyst and preparation method and application thereof

A combustion catalyst, protein-based technology, applied in combustion methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low-temperature catalytic performance, etc., achieve easy preparation, wide application fields, and improve chlorine resistance and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

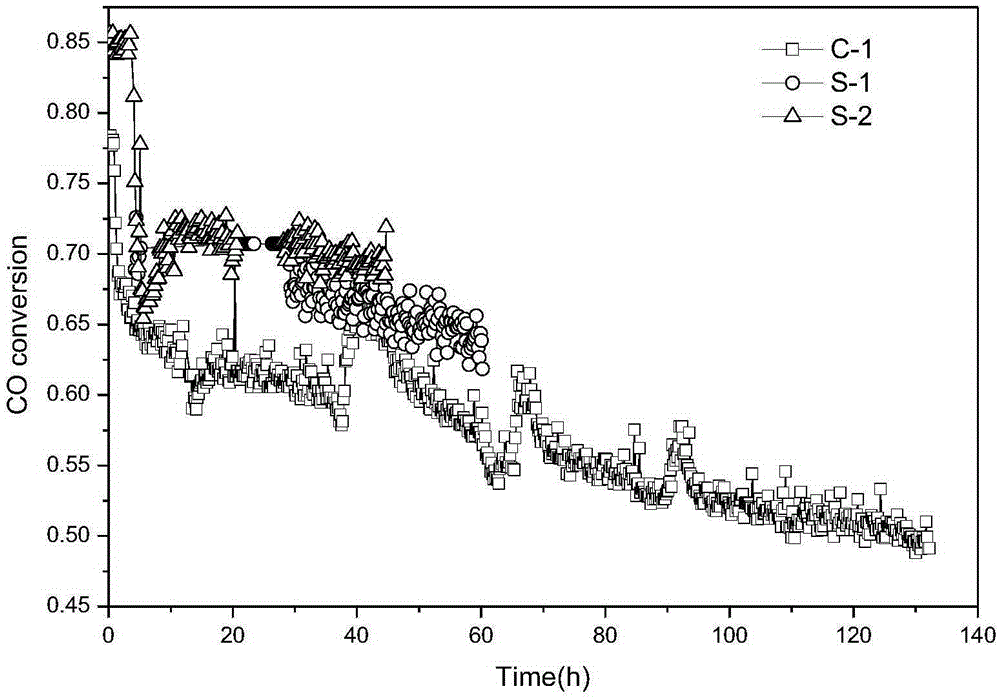

Embodiment 1

[0037] Weigh TiO prepared from metatitanic acid 2 Powder 15g, add 17.5ml ball-milling acid, at 500 rev / min rotating speed, ball mill for 2 hours, the prepared TiO 2 The slurry is coated on the blank monolithic honeycomb, dried by microwave for 6-12min; then baked at 600°C for 4 hours; the coated TiO 2 The honeycomb catalyst was soaked in a solution containing 6mg / mlPt-3mg / mlPd for 3min, then taken out, and dried by microwave for 3min; then, it was roasted at 500°C for 2 hours; TiO 2Immerse in slurry for 2-3min, then microwave dry for 3min, then bake at 500°C for 2 hours; TiO 2 / Pt0.2%-Pd0.1% / TiO 2 / monolith catalyst (marked: S-1). The prepared catalyst was heated at 450°C in 10% H 2 -90%N 2 Reduction under atmosphere for 2 hours, then in 83.69% N 2 (dry basis), 11.05% O 2 (dry basis), 5.26% CO 2 (dry basis), 100-200ppmCO, 9%H 2 O, 30ppm Cl - Under working conditions, test the performance of the catalyst.

Embodiment 2

[0039] Weigh TiO prepared from metatitanic acid 2 Powder 15g, add 17.5ml ball-milling acid, at 500 rev / min rotating speed, ball mill for 2 hours, the prepared TiO 2 The slurry is coated on the blank monolithic honeycomb, dried by microwave for 6-12min; then baked at 600°C for 4 hours; the coated TiO 2 The honeycomb catalyst was soaked in a solution containing 6mg / mlPt-3mg / ml Pd for 3min, then taken out, dried in microwave for 3min; then, calcined at 500°C for 2 hours; Pt0.2%-Pd0.1% / TiO 2 / monolith catalyst.

[0040] Then take the TiO prepared from metatitanic acid 2 Powder 5g, add 6ml ball-milling acid, then add a small amount of PVP, at 500 rpm speed, ball mill for 2 hours, the prepared TiO 2 slurry, diluted with water. Then the above prepared Pt0.2%-Pd0.1% / TiO 2 / monolith catalyst, soaked in the diluted slurry slurry for 3 minutes, took out, dried in microwave for 3 minutes; then, calcined at 500°C for 2 hours; TiO 2 / Pt0.2%-Pd0.1% / TiO 2 / monolith catalyst (marked: S-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com