Cobalt-based oxygen generating catalyst, preparation method thereof and alkaline hydrogen-generating electrolyzer

An oxygen catalyst and cobalt-based technology, applied in the field of nanomaterials, can solve the problems of material morphology difference and low catalytic performance, and achieve the effects of excellent catalytic performance, simple method steps and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a cobalt-based oxygen-generating catalyst, comprising the following steps:

[0040] A) Preparation of CoMoO 4 Nanorod precursors;

[0041] B) the CoMoO 4 The nanorod precursor is dispersed into the solution of the anion precursor, and the anion is exchanged through a hydrothermal reaction to obtain a cobalt-based catalyst; the anion precursor is selected from metal hydroxide, metal sulfide, metal selenide or phosphate compound.

[0042] The present invention first prepares CoMoO 4 nanorod precursor, the CoMoO 4 The nanorod precursor is prepared as follows:

[0043] Mix cobalt salt, molybdate and deionized water to obtain a mixed solution;

[0044]The mixed solution is reacted under the condition of 120-180°C, followed by separation, washing and drying in order to obtain CoMoO 4 Nanorod precursors.

[0045] Specifically, cobalt salt and molybdate are added into deionized water to obtain a mixed solution. Among them, t...

Embodiment 1

[0063] (1)CoMoO 4 Preparation of nanorod precursors:

[0064] 2mmol Co(NO 3 ) 2 ·6H 2 O and 2 mmol Na 2 MoO 4 2H 2 O was respectively dissolved in 17.5ml deionized water, and stirred to fully dissolve; the above-mentioned Na 2 MoO 4 solution was added to Co(NO 3 ) 2 solution, stirred for 10 minutes to form a uniform mixed solution; transferred the mixed solution to a 50ml reaction kettle, put it in a 150°C oven, and reacted for 6 hours; took out the reaction kettle, observed a large number of purple precipitates, centrifuged and washed twice with distilled water , washed once with ethanol, and dried in a vacuum oven at 60°C for 12 hours to obtain CoMoO 4 Nanorod precursors.

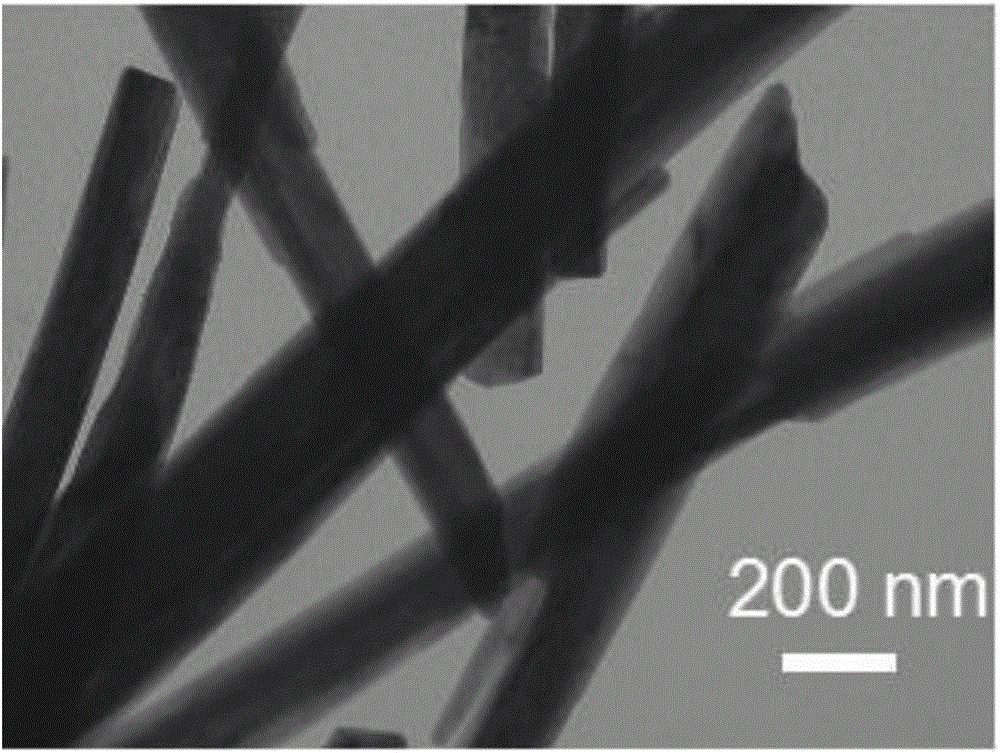

[0065] For the above CoMoO 4 The nanorod precursor was observed by transmission electron microscopy, and the results are shown in figure 1 , figure 1 For the CoMoO that embodiment 1 obtains 4 Transmission electron micrographs of nanorod precursors. From figure 1 It can be seen that CoMoO ...

Embodiment 2

[0070] According to the preparation method of Example 1, the preparation of the cobalt-based oxygen-generating catalyst has the following differences: when preparing the anion precursor solution, 20 mL of water is selected as the reaction solvent to obtain Co(OH) 2 Material.

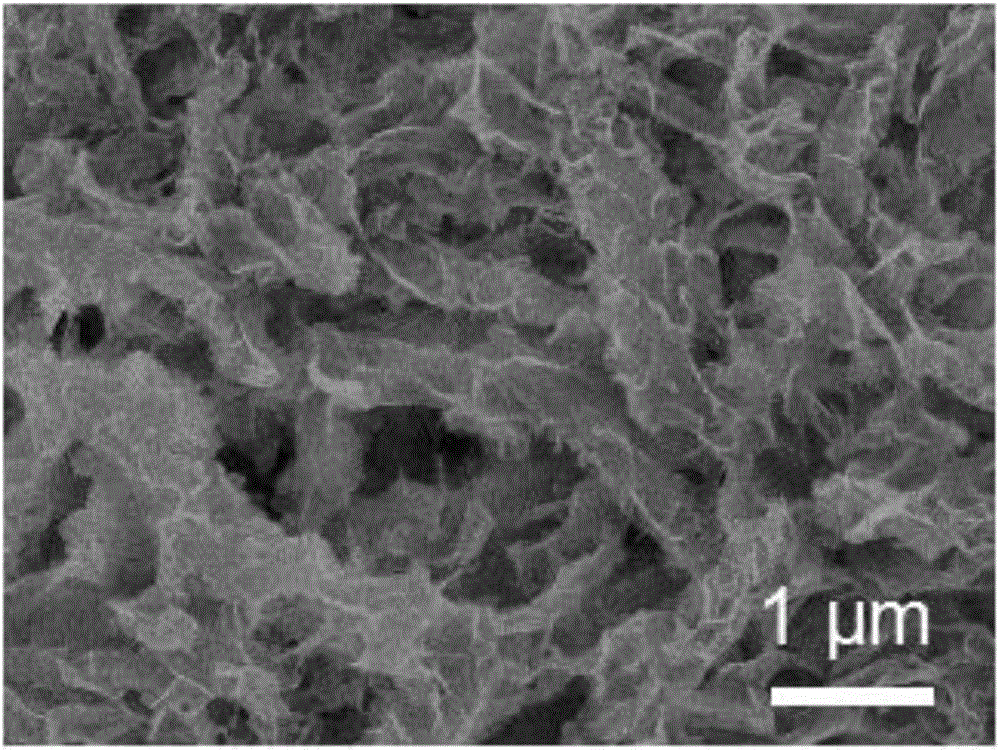

[0071] The obtained material is subjected to scanning electron microscope analysis, and the results can be found in Figure 4 , Figure 4 Co(OH) obtained for Example 2 2 Scanning electron micrographs of the material. With the Co(OH) that embodiment 1 obtains 2 Material is compared, the Co(OH) that present embodiment 2 obtains 2 There is no obvious difference in the morphology of the material, and it is still a one-dimensional structure composed of nanosheets, with a diameter of about 300-400nm, composed of Co(OH) 2 The size of the nano sheet on the surface of the material is 50-100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com