Oxidation 1090 mirror aluminum mirror machining method

A technology of mirror surface processing and mirror surface aluminum, which is applied in the direction of contour control, rolling force/roll gap control, metal rolling, etc., can solve the problem that the oxidation plate has not made a breakthrough, and achieve obvious product market competitiveness and low production cost , significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

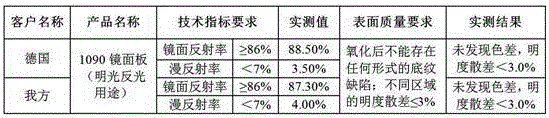

[0023] Taking the production of 1090 mirror aluminum for oxidation with a finished mirror thickness of 0.58mm as an example, the mirror rolling equipment adopts an ordinary single-stand irreversible mirror rolling mill.

[0024] (1) The mirror wool is 1.2mm×1270mm H16 1090 mirror wool. The measured tensile strength is 115MPa and the elongation is 8.5%. It is confirmed that there is no surface chromatic aberration on the surface of the mirror wool.

[0025] (2) Process lubrication and work rolls for mirror rolling: use Qingjiang No. 90 base oil (n-paraffin content ≥ 45%) as the base oil, and add corresponding additives (generally C12 alcohol and C12 ester) to the base oil to prepare rolling rolls. For oil production, the additive content is 2.0-3.0% (volume), the ester / alcohol volume ratio is 1.2-1.8:1, the viscosity of the rolling oil is ≤2.0cst, and the oil temperature is controlled at 30±2°C, so that the lubrication of the rolling oil is controlled The effect and the strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com