Hydrophobic bamboo wood with surface being loaded with oxidized graphene and silicon dioxide and production technology thereof

A surface-loaded, silica-based technology, applied in wood processing appliances, wood treatment, wood heating, etc., can solve the problems that bamboo affects human health and cannot meet the hydrophobic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

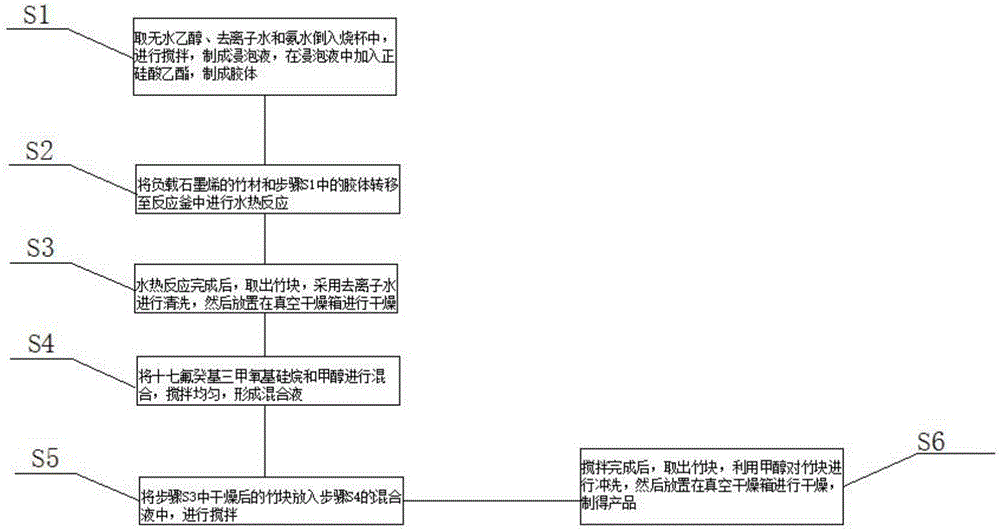

[0031] A kind of production technology of the bamboo material of surface loading graphene oxide and silicon dioxide, comprises the following steps:

[0032] S1: Pour anhydrous ethanol, deionized water and ammonia water into a beaker, stir to make a soaking solution, add tetraethyl orthosilicate to the soaking solution to make a colloid;

[0033] S2: transferring the bamboo material loaded with graphene oxide and the colloid in step S1 to a reactor for hydrothermal reaction;

[0034] S3: After the hydrothermal reaction is completed, the bamboo block is taken out, cleaned with deionized water, and then placed in a vacuum drying oven for drying;

[0035] S4: Mix heptadecafluorodecyltrimethoxysilane and methanol, and stir evenly to form a mixed solution;

[0036] S5: Put the dried bamboo pieces in step S3 into the mixed solution in step S4, and stir;

[0037] S6: After the stirring is completed, take out the bamboo block, rinse the bamboo block with methanol, and then place it i...

Embodiment 2

[0049] A kind of production technology of the bamboo material of surface loading graphene oxide and silicon dioxide, comprises the following steps:

[0050] S1: Pour anhydrous ethanol, deionized water and ammonia water into a beaker, stir to make a soaking solution, add tetraethyl orthosilicate to the soaking solution to make a colloid;

[0051] S2: transferring the bamboo material loaded with graphene oxide and the colloid in step S1 to a reactor for hydrothermal reaction;

[0052] S3: After the hydrothermal reaction is completed, the bamboo block is taken out, cleaned with deionized water, and then placed in a vacuum drying oven for drying;

[0053] S4: Mix heptadecafluorodecyltrimethoxysilane and methanol, and stir evenly to form a mixed liquid;

[0054] S5: Put the dried bamboo pieces in step S3 into the mixed solution in step S4, and stir;

[0055]S6: After the stirring is completed, take out the bamboo block, rinse the bamboo block with methanol, and then place it in a...

Embodiment 3

[0065] A kind of production technology of the hydrophobic bamboo material of surface loading graphene oxide and silicon dioxide, comprises the following steps:

[0066] S1: Pour anhydrous ethanol, deionized water and ammonia water into a beaker, stir to make a soaking solution, add tetraethyl orthosilicate to the soaking solution to make a colloid;

[0067] S2: transferring the bamboo material loaded with graphene oxide and the colloid in step S1 to a reactor for hydrothermal reaction;

[0068] S3: After the hydrothermal reaction is completed, the bamboo block is taken out, cleaned with deionized water, and then placed in a vacuum drying oven for drying;

[0069] S4: Mix heptadecafluorodecyltrimethoxysilane and methanol, and stir evenly to form a mixed liquid;

[0070] S5: Put the dried bamboo pieces in step S3 into the mixed solution in step S4, and stir;

[0071] S6: After the stirring is completed, take out the bamboo block, rinse the bamboo block with methanol, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com