A method for treating sewage by using garbage incinerator slag

A technology for waste incineration slag and sewage, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc. and other issues, to achieve important practical value, good social and environmental benefits, and the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

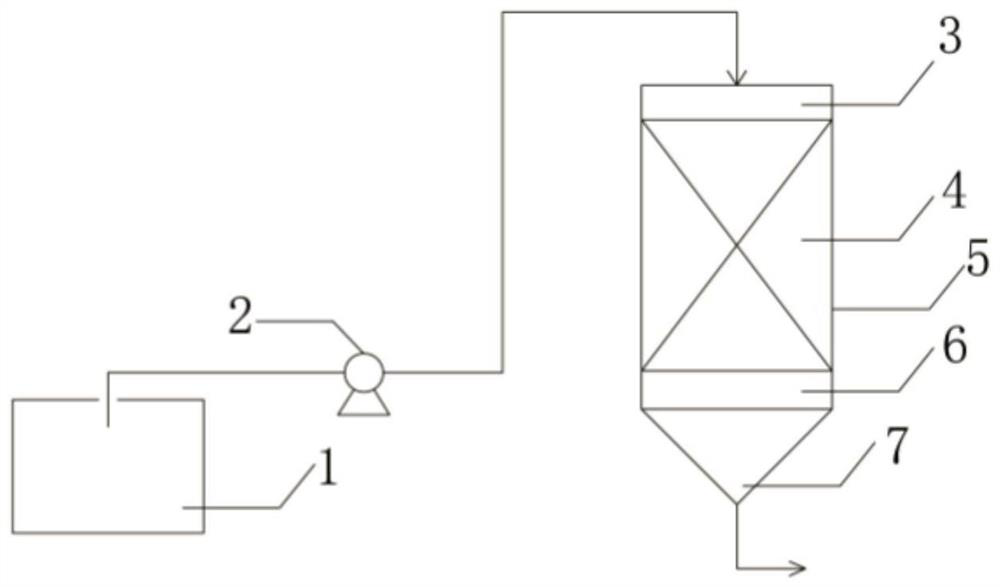

[0029] The reaction bed that the present invention adopts, as figure 1 As shown, the reaction bed includes a reaction bed shell 5, the reaction bed shell 5 is cylindrical, the reaction bed shell 5 is provided with a packing layer 4 and a supporting layer 6 from top to bottom, and the packing layer 4 is composed of garbage incineration slag, Garbage incineration slag is inoculated with activated sludge, the supporting layer 6 is composed of crushed stones, the top of the reaction bed shell 5 is provided with a water distribution area 3 for spraying sewage, the bottom of the reaction bed shell 5 is provided with a water outlet 7 connected to the sump, and the sewage The sewage in the reservoir 1 is transported to the upper part of the reaction bed device through the pump 2 .

[0030] The specific steps are:

[0031] (1) The domestic waste incineration slag used in the test was taken from the Shanghai Laogang Solid Waste Comprehensive Utilization Base, and the retrieved incinera...

Embodiment 2

[0039] (1) The domestic waste incineration slag used in the test was taken from the Shanghai Laogang Solid Waste Comprehensive Utilization Base, and the retrieved incineration slag was evenly dispersed, and the broken stones, broken glass, iron pieces or those that were not completely burned were removed. Rubber and other sundries;

[0040] (2) Screening the domestic waste slag obtained in step (1) to obtain particles in the range of 5 to 8 mm in particle size, and washing the obtained domestic waste incineration slag with tap water and drying to obtain the filler for the domestic waste incineration slag reaction bed;

[0041] (3) select internal diameter to be 20cm, and height is the cylindrical container of 200cm as reaction bed, and reaction bed is equipped with the slag that step (2) obtains as the biofiller of reaction bed, and its height is 180cm. The bottom of the reaction bed is equipped with pebbles with a height of 20cm to act as a supporting layer;

[0042] (4) Get...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com