Method for producing paraxylene by using suspension melt crystallization

A suspension melt crystallization, para-xylene technology, applied in crystallization purification/separation, organic chemistry, etc., can solve the problems of wide particle size distribution, small average particle size, complex process, etc., and achieve wide particle size distribution and small particle size. , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for producing p-xylene by suspension melting crystallization described in the present invention.

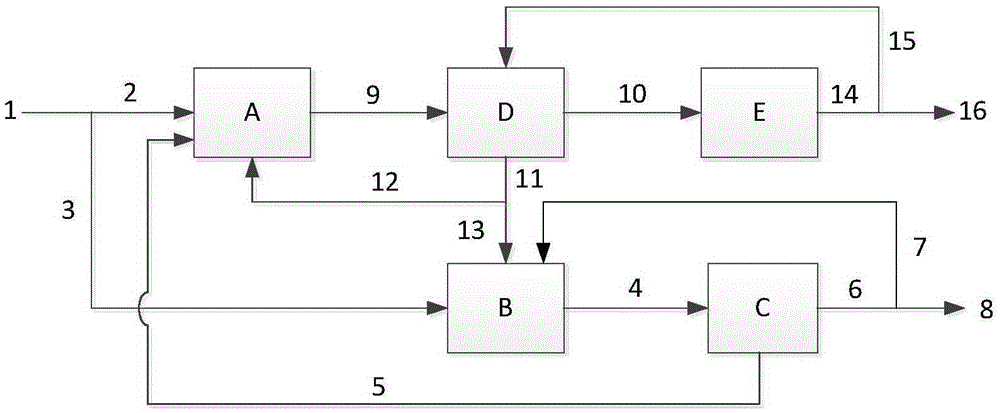

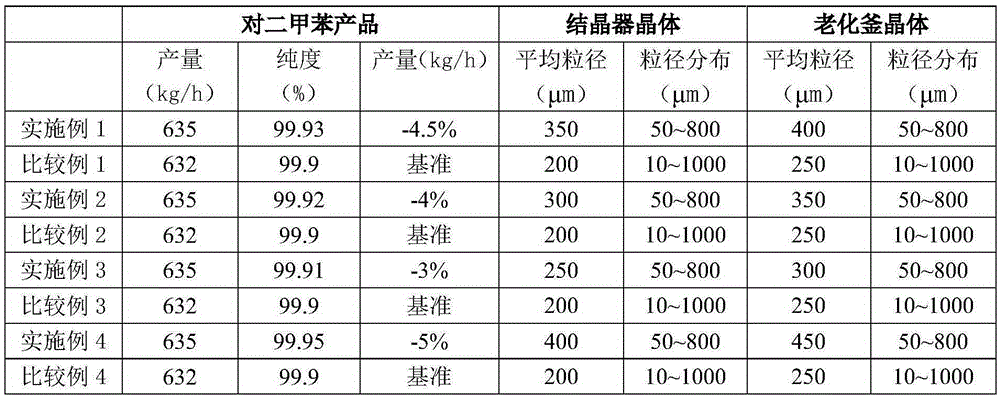

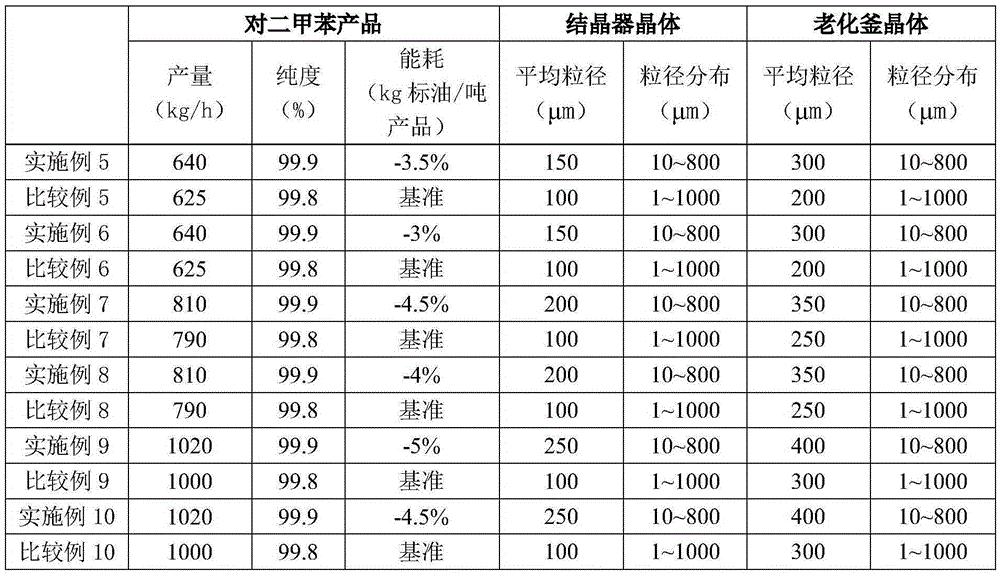

[0024] Such as figure 1As mentioned above, the raw material 1 containing p-xylene concentration of 82% has a flow rate of 1075kg / h. It is precooled from 50°C to 15°C and divided into two strands. One strand of raw material 2 enters the aging kettle A with a flow rate of 645kg / h. , another stream of raw material 3 enters in the crystallizer B, and the flow rate is 430kg / h; The residence time in B is 30 minutes, and the magma 4 separates p-xylene crystal 5 and crystallization mother liquor 6 through solid-liquid separator C, and p-xylene crystal 5 enters in aging kettle A, and its average particle diameter is 350 μ m, crystal The particle size distribution range is 50 μm to 800 μm, the crystallization mother liquor 6 is divided into two streams, the first crystallization mother liquor 7 accounting for 55% by weight returns to the crystallizer, and the second crys...

Embodiment 2

[0028] The method for producing p-xylene by suspension melting crystallization described in the present invention. According to the operating conditions of Example 1, wherein, the flow rate of raw material 2 into the aging kettle A is 215kg / h, the operating temperature of the aging kettle is 5.5°C, the crystal content in the magma is 35%, and the operating temperature of the crystallizer is -8 ℃, the crystal content in the magma is 35%, and the results are listed in Table 1.

Embodiment 3

[0032] The method for producing p-xylene by suspension melting crystallization described in the present invention. The method for producing p-xylene by suspension melting crystallization described in the present invention. According to the operating conditions of Example 1, wherein, the flow rate of raw material 2 into the aging kettle A is 0kg / h, the operating temperature of the aging kettle is 4°C, the crystal content in the magma is 35%, and the operating temperature of the crystallizer is -8°C. ℃, the crystal content in the magma is 35%, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com