Method for preparing n-pentene by n-amyl alcohol dehydration

A technology of n-pentanol and pentene, which is applied in the field of preparation of n-pentene, can solve the problems of little introduction of n-pentene technology, and achieve the effect of good reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

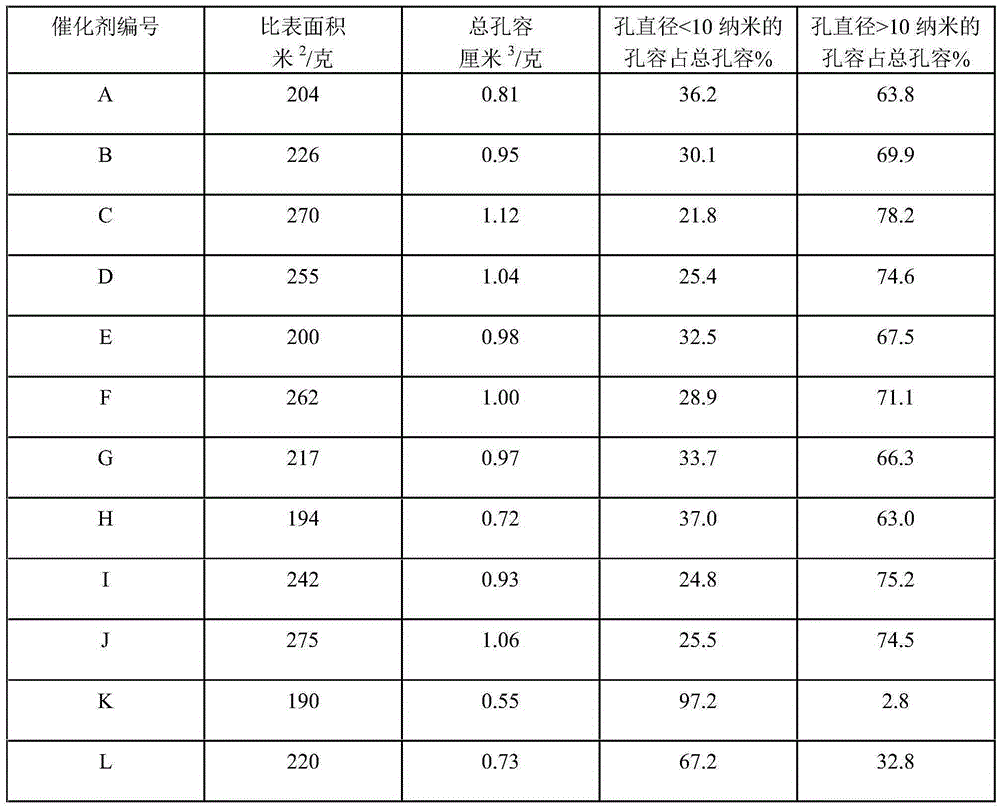

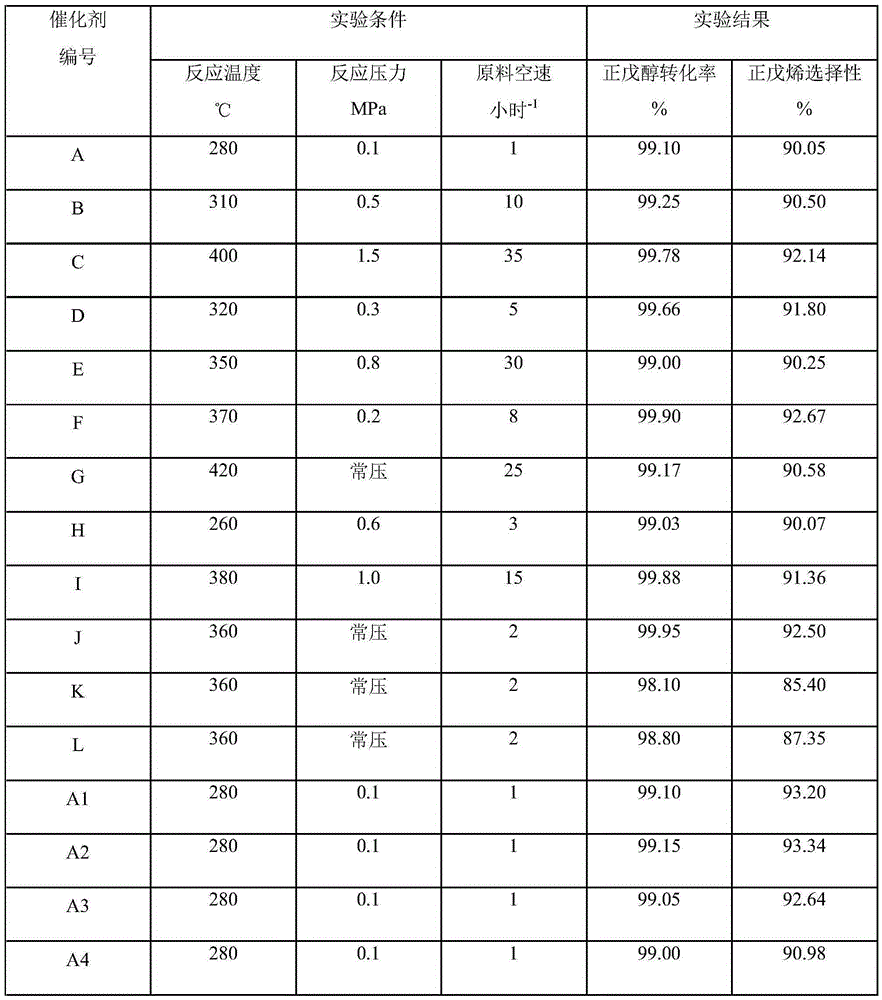

[0025] Weigh 500 grams of pseudo-boehmite, 200 grams of cellulose methyl ether and 24 grams of sesame powder in a kneader and knead for 30 minutes, add 500 ml of 5% nitric acid solution, knead for another 10 minutes, and then extrude into a strip at 110°C After drying for 10 hours, it was activated in a muffle furnace at 650°C for 8 hours to obtain catalyst A. The physical properties of the catalyst are shown in Table 1. The catalyst performance evaluation test was carried out on a fixed-bed tubular reactor (Ф25×500 mm stainless steel) with a catalyst loading capacity of 10 ml. The experimental conditions and reaction results are shown in Table 2.

Embodiment 2

[0027] Weigh 300 grams of aluminum hydroxide, 150 grams of polyethylene glycol (4000), and 15 grams of sesame powder. Knead in a kneader for 30 minutes, add 200 ml of 5% nitric acid solution, knead for another 15 minutes, and then extrude to form 120 It was dried at ℃ for 8 hours, and then activated in a muffle furnace at 600 ℃ for 10 hours to obtain catalyst B. The physical properties of the catalyst are shown in Table 1. The catalyst performance evaluation test was carried out on a fixed-bed tubular reactor (Ф25×500 mm stainless steel) with a catalyst loading capacity of 10 ml. The experimental conditions and reaction results are shown in Table 2.

Embodiment 3

[0029] Weigh 200 grams of boehmite, 150 grams of polyoxyethylene, and 10 grams of sesame powder. Knead in a kneader for 30 minutes, add 200 ml of 5% nitric acid solution, knead for another 25 minutes, and then extrude and dry at 110°C for 15 minutes. Then, it was activated in a muffle furnace at 500°C for 6 hours to obtain catalyst C. The physical properties of the catalyst are shown in Table 1. The catalyst performance evaluation test was carried out on a fixed-bed tubular reactor (Ф25×500 mm stainless steel) with a catalyst loading capacity of 10 ml. The experimental conditions and reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com