Preparation method of 25-hydroxyl-7-dehydrocholesterol

A technology of dehydrocholesterol and triene cholesterol, applied in the direction of steroids, organic chemistry, etc., can solve problems such as difficult industrialization, excessive mercury content, and major environmental protection problems, and achieve cost reduction of three wastes, good reaction selectivity, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

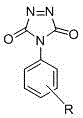

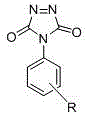

Image

Examples

Embodiment 1

[0026] Example 1 According to the preparation method of the present invention, 25-hydroxy-7-dehydrocholesterol was prepared.

[0027] 1) Protection of the 3-position hydroxyl group to obtain intermediate compound Ⅱ

[0028] At room temperature (25°C), dissolve 3.82 g (10 mmol) of 5,7,24-triene cholesterol in 40 ml

[0029] In dichloromethane, add 0.06g (0.5mmol) DMAP, 2.04g (20mmol) acetic anhydride, 3.03g

[0030] (30mmol) triethylamine, stirred and reacted at room temperature for 3h, after TLC traced the complete reaction, added 15ml10%

[0031] Dilute hydrochloric acid layered to remove the water phase, the organic phase was washed with 15ml of water and layered, and the organic phase was dried with anhydrous sodium sulfate

[0032] Filtration and concentration gave a pale yellow crude product, which was recrystallized from methanol to obtain 3.89 g of intermediate compound II with a yield of 91.6% and a melting point of 82-84°C. 1 H NMR (400 MHz, CDCl 3 ) δ 5.56 (m, 1H...

Embodiment 2

[0041] According to the method in step 1) of Example 1, the only difference is that acetic anhydride is replaced by benzoic anhydride, and the molar ratio of 5,7,24-triene cholesterol, protective reagent, catalyst, and acid-binding agent is adjusted to 1:1.5: 0.01:1.5, other operations are the same as step 1), and the yield of intermediate II is 84.5%.

Embodiment 3

[0043] According to the method in step 1) of Example 1, the only difference is that acetic anhydride is replaced by acetyl chloride, and the molar ratio of 5,7,24-triene cholesterol, protective reagent, catalyst, and acid-binding agent is adjusted to 1:3:0.06 : 5, other operations are the same as step 1), and the yield of intermediate II is 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com