Nylon hose and preparation technique thereof

A hose and nylon technology, applied in the field of nylon hose and its preparation, can solve the problems of unusable products, cracks in cable sleeves, etc., and achieve the effects of strong energy absorption capacity, high strength, and low elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

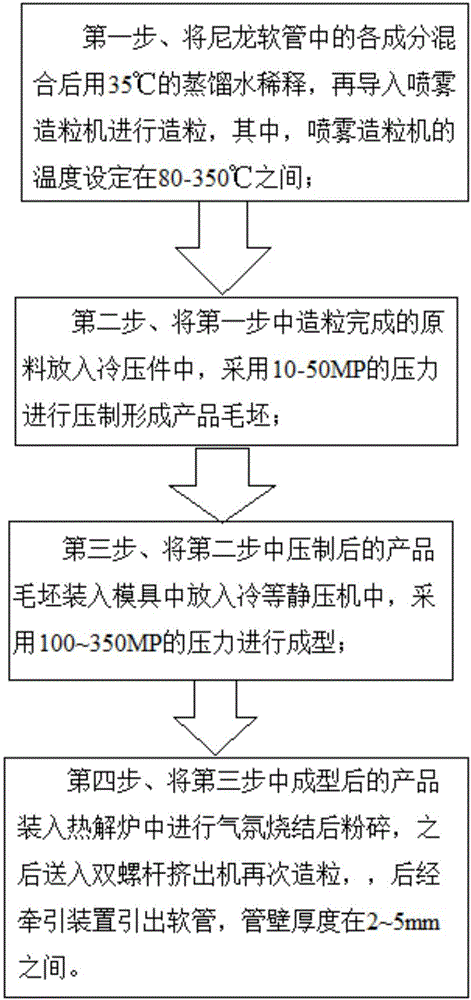

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the invention, and are not intended to limit the invention.

[0019] The ratios of the components in the nylon hose of the present invention are: 35 parts of silicon carbide grains, 1-1.4 parts of composite slag powder, 0.5-4 parts of medical stone powder, and 0.5-1.3 parts of graphene. The appliance made of the nylon hose has high strength and is not easy to crack, and the prepared appliance can continuously exude the beneficial element boron that meets the needs of the human body during use, so as to meet the needs of the human body for its trace elements .

[0020] During specific implementation, the ratios of the components of the first embodiment of the nylon hose of the present invention are: 35 parts of silicon carbide grains, 1 part of compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com