Cold-coating quick-drying type colored pavement antiskid coating

A non-slip and quick-drying technology for road surfaces, applied in the direction of coating, etc., can solve the problems of low construction efficiency, poor durability, poor temperature change, etc., and achieve the effect of convenient construction, good durability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

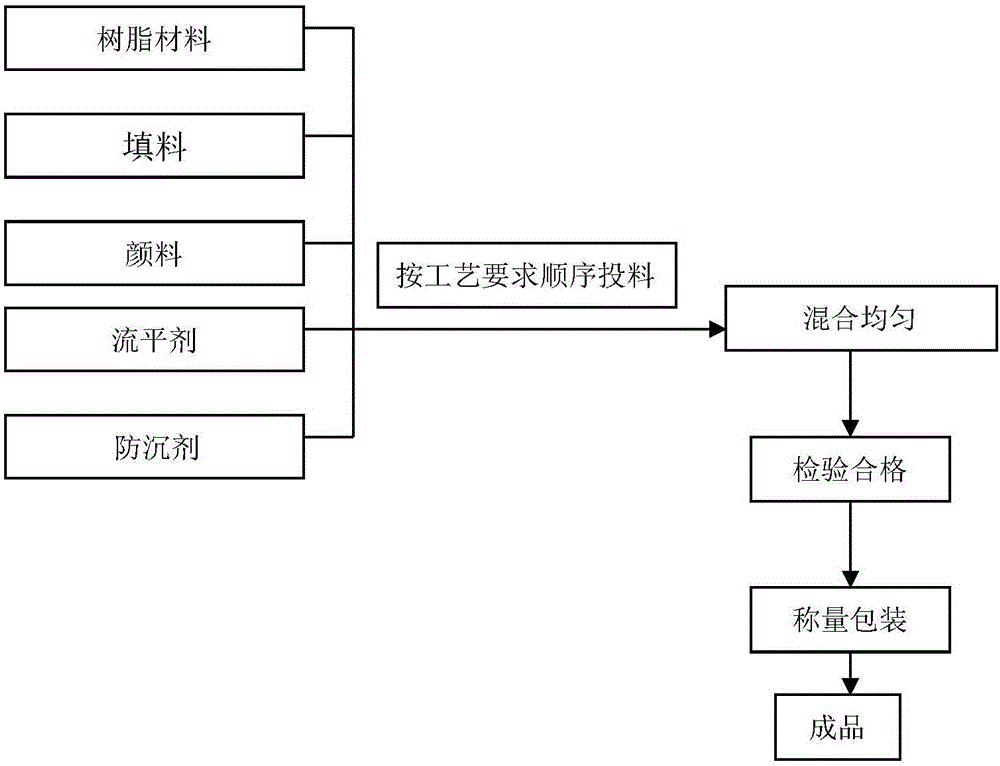

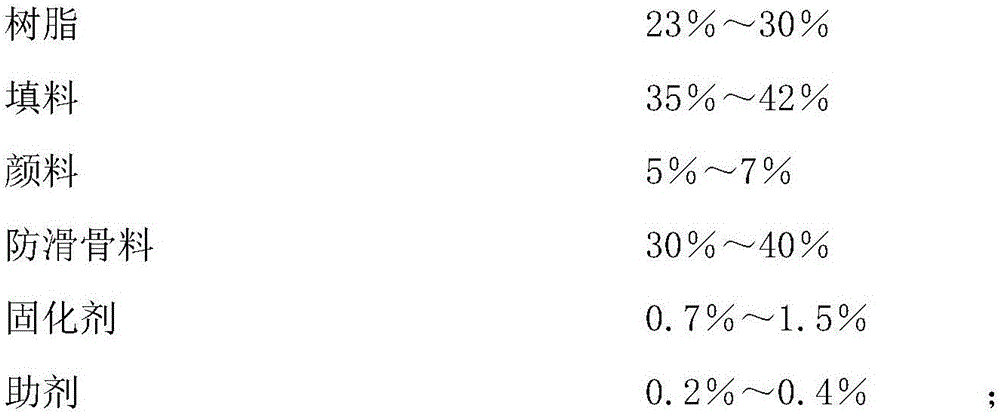

Method used

Image

Examples

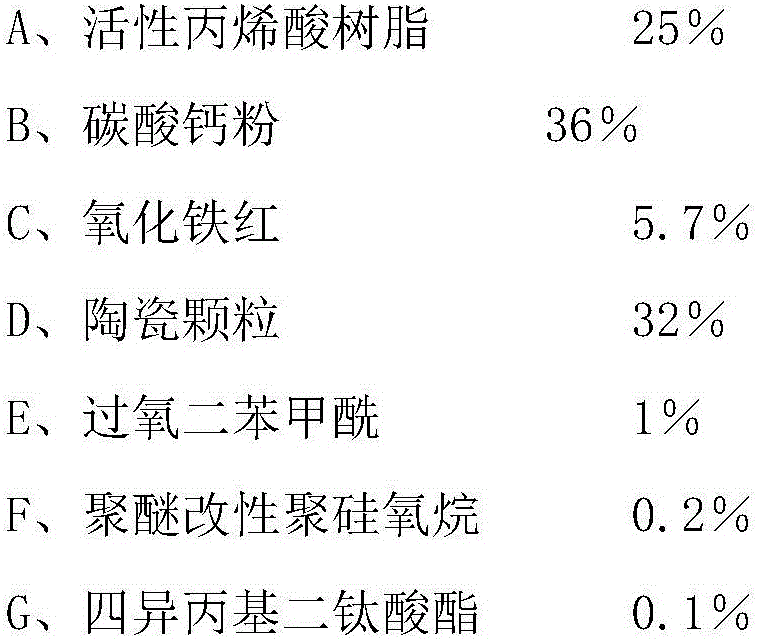

Embodiment 1

[0062]

[0063] The formula has good skid resistance and anti-aging properties, and is mainly suitable for accident-prone areas and curves, up and down ramps, parking lots, expressway toll stations, etc.

Embodiment 2

[0065]

[0066] The formula has good skid resistance and anti-aging properties, and is mainly suitable for accident-prone areas and curves, up and down ramps, parking lots, expressway toll stations, etc.

Embodiment 3

[0068]

[0069] The formula has good skid resistance and anti-aging properties, and is mainly suitable for accident-prone areas and curves, up and down ramps, parking lots, expressway toll stations, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com