Adhesive film for bonding composite boards and its preparation method and application

A technology for composite boards and boards, applied in chemical instruments and methods, film/sheet adhesives, adhesives, etc., can solve the problems of low moisture content, increase energy consumption, energy waste, etc., and achieve boiling-resistant bonding strength performance , High bonding strength performance, the effect of shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the adhesive film described in the above technical solution, comprising: coating the thermosetting resin on both sides of the polyolefin surface and then baking to obtain the adhesive film.

[0035] In the present invention, the coating process preferably adjusts the pH of the thermosetting resin to 10-13, more preferably 11-12.5, more preferably 12. In the present invention, the limitation of the pH value is to effectively improve the activity of the glue, reduce the volatile content of the resin glue, and then improve the stability of the resin glue, increase the storage time, and ensure that the resin glue is coated on both sides of the polyolefin surface. maintain a certain degree of pre-curing. In the present invention, the adjustment of the pH value is preferably by mixing the thermosetting resin with an alkaline substance; in the present invention, the alkaline substance is preferably potassium hydroxide,...

Embodiment 1

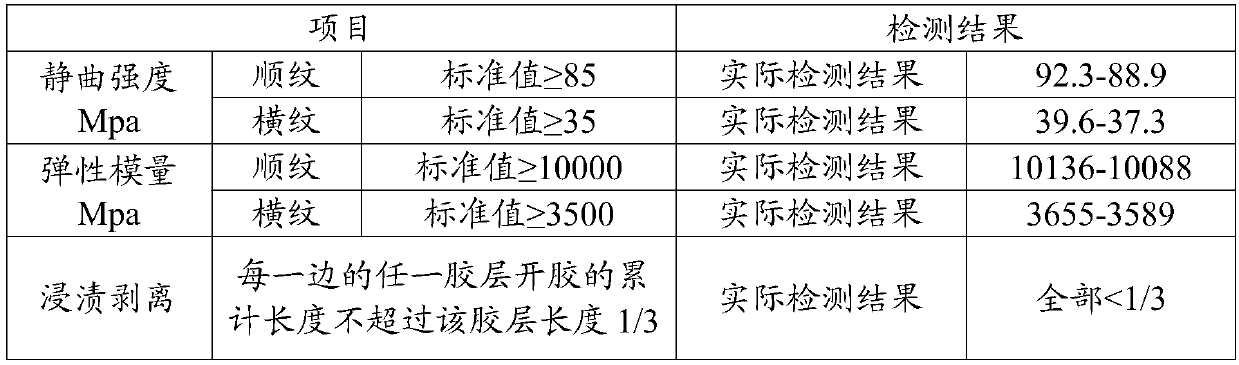

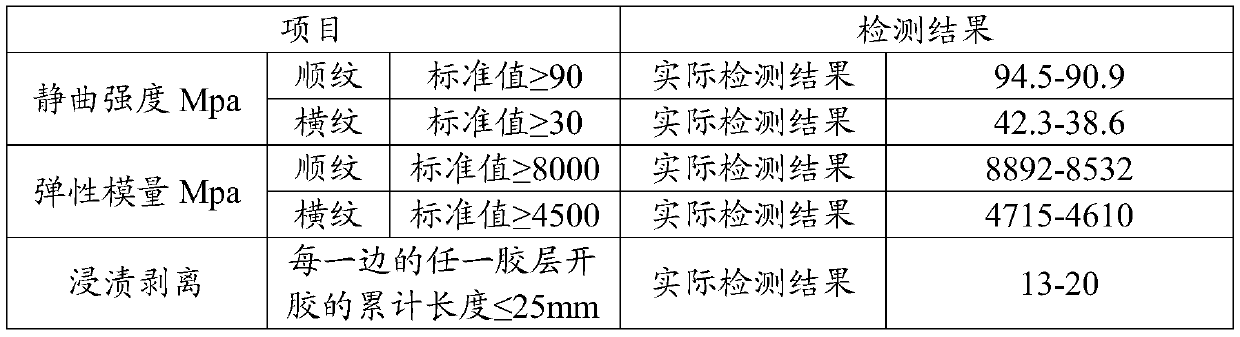

[0064] Preparation of all-bamboo container floor:

[0065] Preparation of adhesive film for composite board: adjust the pH value of phenolic resin with a solid content of 45wt% and a viscosity of 30s at 25°C to 13, and then spray it on both surfaces of polyethylene plastic, wherein the quality of the phenolic resin is poly 35% of the mass of vinyl plastic; then dry at 50°C for 3 minutes to obtain a film.

[0066] The moisture of the whole bamboo board is dried to a moisture content of 19wt%, and the surface of the board is 83.8g / m 2 After coating the prepared adhesive film according to the standard, it is bonded to another board; then the adhesive film is coated on the unbonded surface of the other board, and so on. body.

[0067] According to 26kgf / cm 2 The standard defines the pressure value of hot pressing. Under the condition of 5.0MPa, the temperature is raised to 140°C in the core layer, and the heating time is determined according to the heating time standard of 1min...

Embodiment 2

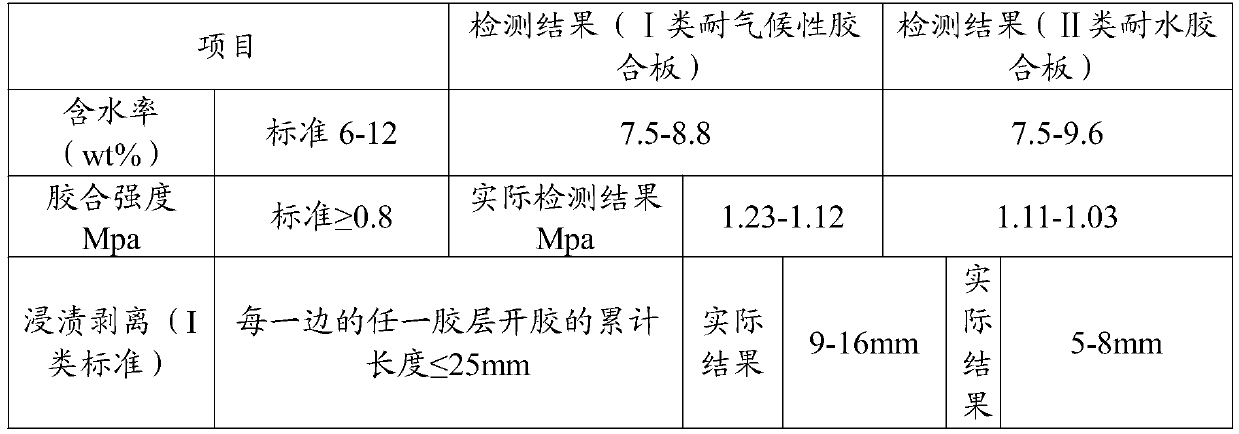

[0073] Preparation of all-wood Class I weather-resistant plywood:

[0074] Preparation of adhesive film for composite board: adjust the pH value of phenolic resin with a solid content of 45wt% and a viscosity of 150s at 25°C to 13, and then spray it on both surfaces of polypropylene plastic, wherein the quality of the phenolic resin is polyethylene 5% of the plastic mass; then dry at 50°C for 3 minutes to obtain a film.

[0075] Dry the moisture of the whole wood board until the water content is 7.5-8.8wt%, and the surface of the board shall be 25.5g / m 2After coating the prepared adhesive film according to the standard, it is bonded to another board; then the adhesive film is coated on the unbonded surface of the other board, and so on. body.

[0076] According to 10~12kgf / cm 2 The standard defines the pressure value of hot pressing. Under the condition of 2.0MPa, the heating time is determined according to the heating time standard of 0.7min per unit millimeter thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com