Method and device for preparing water coke slurry from semicoke

A technology for water coke pulp and semi-coke, which is applied in the field of semi-coke preparation of water coke pulp, and can solve the problems of difficulty in realizing industrial scale-up of semi-coke pulp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

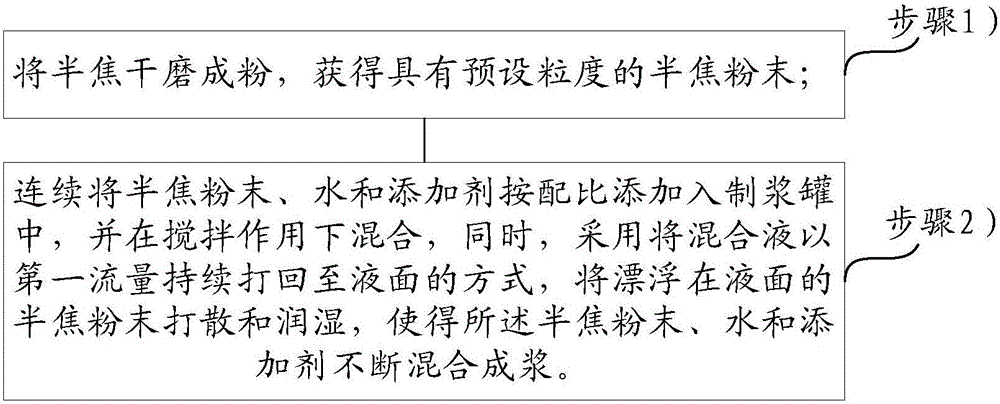

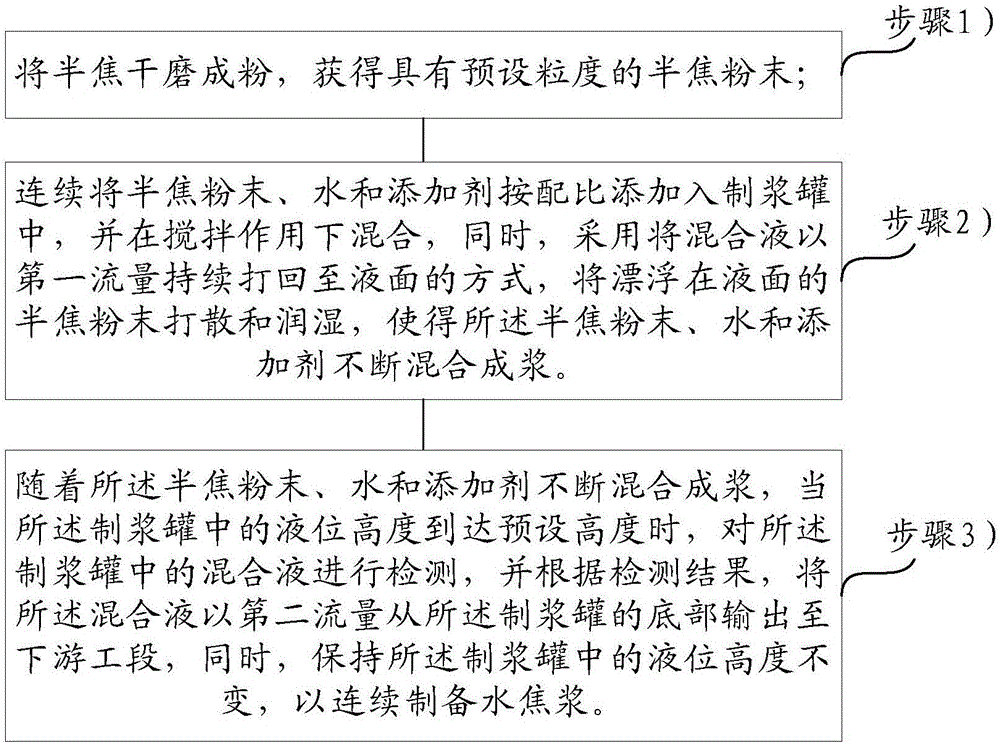

[0048] Embodiment 1 of the present invention provides a method for preparing water coke slurry with semi-coke, see figure 1 ,include:

[0049] Step 1) dry-grinding semi-coke into powder to obtain semi-coke powder with a preset particle size;

[0050] Among them, semi-coke is a kind of porous fine powder produced after coal pyrolysis or gasification. Exemplarily, the particle size of hydrogenated gasification semi-coke is mostly 50-60 microns, and the porosity can reach more than 80%. When the semi-coke is directly slurried, on the one hand, the hydrophobicity of the semi-coke is extremely high, making it difficult to directly slurry; on the other hand, the prepared hydrocoke slurry has certain requirements on particle size; therefore, the Before semi-coke is made into slurry, it is necessary to break the pore structure of semi-coke to obtain semi-coke powder with a preset particle size, so as to reduce the hydrophobicity of semi-coke and meet the slurrying requirements of sem...

Embodiment 2

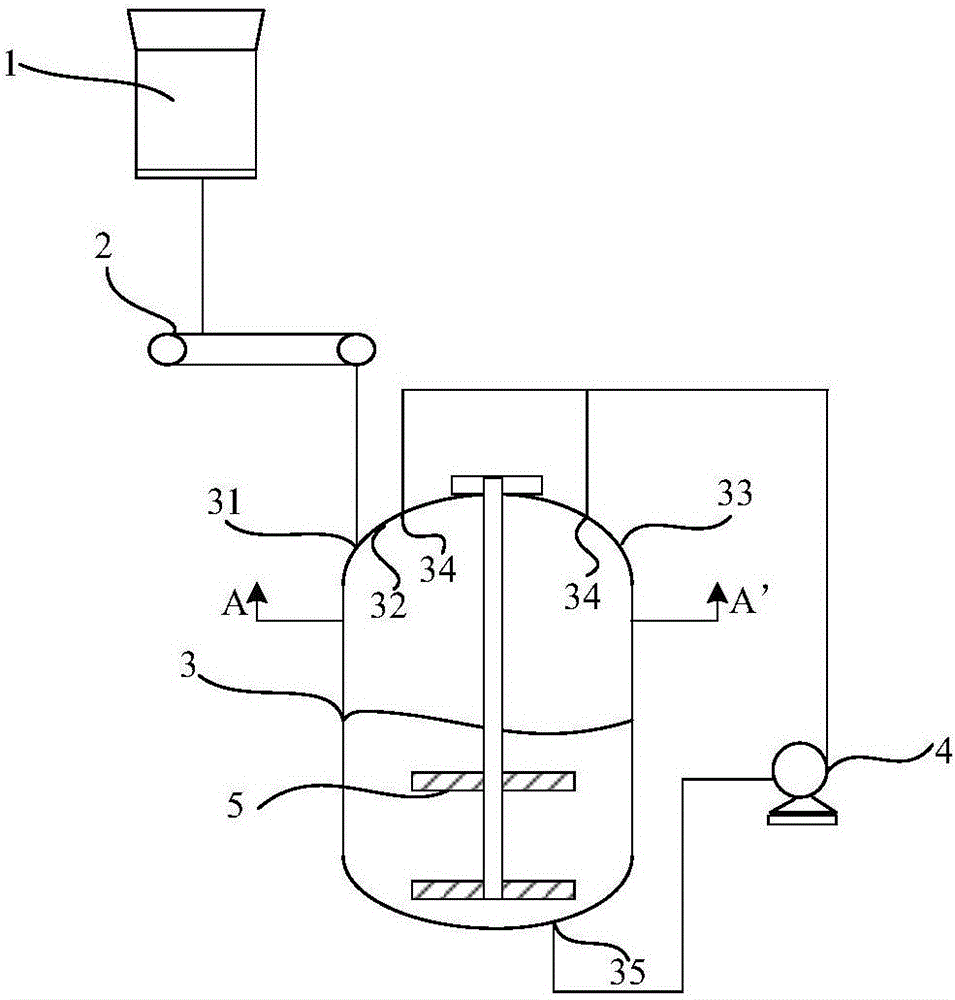

[0075] Embodiment 2 of the present invention provides a device for preparing semi-coke pulp with semi-coke, which is applied to the above-mentioned method, see image 3 ,include:

[0076] Semi-coke mill 1, semi-coke feeder 2, slurry tank 3 and return pump 4;

[0077] Wherein, the top of the pulping tank 3 is provided with a semi-coke feed inlet 31, a water inlet 32, an additive inlet 33 and a material return port 34, and the bottom of the pulping tank 3 is provided with a first discharge port 35, so A stirring device 5 is arranged in the pulping tank 3;

[0078] The feeding port of the semi-coke mill 1 communicates with the feeding port of the semi-coke feeder 2, and the semi-coke feeding port 51 is located below the semi-coke feeder 2, and is connected to the semi-coke feeder 2. The discharge port of the semi-coke feeder 2 is connected, the input end of the return pump 4 is connected with the first discharge port 35 , and the output end is connected with the return port 34 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com