Waste plastic environment-friendly cleaning agent and preparation method thereof

A technology for cleaning agents and waste plastics, applied in detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of poor surface transparency and easy residue, etc., and achieve excellent cleaning effect, less residue, and clean surface good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

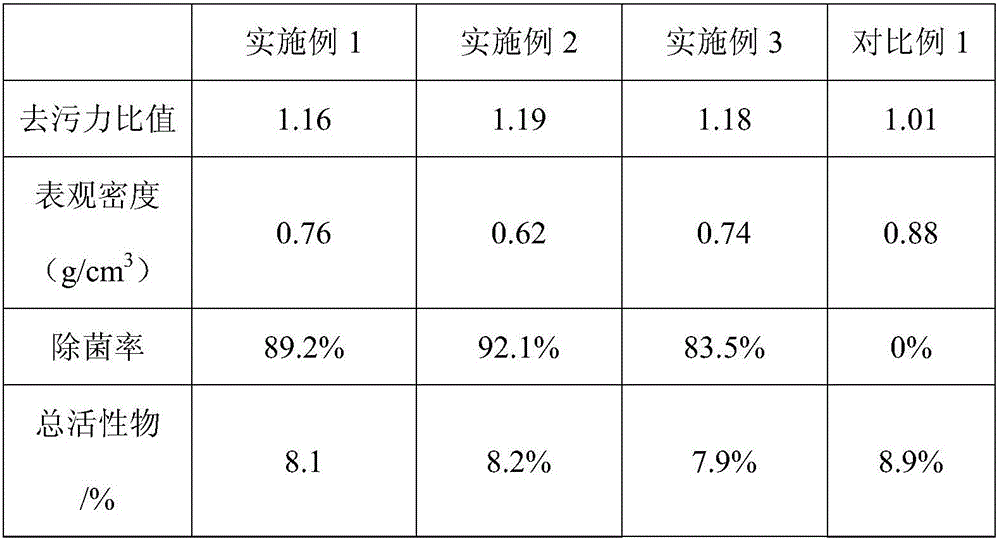

Examples

Embodiment 1

[0022] Consists of the following parts by weight: 20 parts of citric acid, 10 parts of ethyl acetate, 5 parts of alkylphenol polyoxyethylene ether, 5-chloro-2-methyl-4-isothiazolin-3-one 3 parts, 1 part of sodium dodecyl sulfonate, 1 part of modified zeolite, and 40 parts of water.

[0023] The preparation method of the modified zeolite is as follows: Grind the zeolite into 300 mesh powder, use the organic acid modifier malic acid to soak for 5 hours at 70°C, add the organic alkaline reagent triethylamine for neutralization, and neutralize to pH 6, The modified zeolite is obtained by drying and grinding.

[0024] The preparation process steps of the environmentally friendly cleaning agent for waste plastics are as follows:

[0025] (1) Mix 5-chloro-2-methyl-4-isothiazolin-3-one, sodium dodecyl sulfonate and additives, add water, and stir well;

[0026] (2) Mix the fully stirred materials in step (1) with citric acid, ethyl acetate, and alkylphenol polyoxyethylene ether, stir and disp...

Embodiment 2

[0028] It is composed of the following parts by weight: 30 parts of citric acid, 20 parts of ethyl acetate, 10 parts of alkylphenol polyoxyethylene ether, 5-chloro-2-methyl-4-isothiazolin-3-one 3 parts, 3 parts of sodium dodecyl sulfonate, 3 parts of modified zeolite, 40 parts of water.

[0029] The preparation method of the modified zeolite is as follows: Grind the zeolite into a powder of 300 mesh, use the organic acidic modifier lactic acid to soak for 5 hours at 70°C, add the organic alkaline reagent triethylamine for neutralization, neutralize to pH 6, and dry , Grinding to obtain modified zeolite.

[0030] The preparation process steps of the environmentally friendly cleaning agent for waste plastics are as follows:

[0031] (1) Mix 5-chloro-2-methyl-4-isothiazolin-3-one, sodium dodecyl sulfonate and additives, add water, and stir well;

[0032] (2) Mix the fully stirred materials in step (1) with citric acid, ethyl acetate, and alkylphenol polyoxyethylene ether, stir and dispe...

Embodiment 3

[0034] Consists of the following parts by weight: 25 parts of citric acid, 15 parts of ethyl acetate, 10 parts of alkylphenol polyoxyethylene ether, 5-chloro-2-methyl-4-isothiazolin-3-one 3 parts, 3 parts of sodium dodecyl sulfonate, 1 part of modified zeolite, 30 parts of water.

[0035] The preparation method of the modified zeolite is as follows: Grind the zeolite into a powder of 300 mesh, use the organic acid modifier oxalic acid to soak for 5 hours at 70°C, add the organic alkaline reagent triethylamine for neutralization, neutralize to pH 6, and dry , Grinding to obtain modified zeolite.

[0036] The preparation process steps of the environmentally friendly cleaning agent for waste plastics are as follows:

[0037] (1) Mix 5-chloro-2-methyl-4-isothiazolin-3-one, sodium dodecyl sulfonate and additives, add water, and stir well;

[0038] (2) Mix the fully stirred materials in step (1) with citric acid, ethyl acetate, and alkylphenol polyoxyethylene ether, stir and disperse, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com