Ceramic composite material for titanium alloy surface laser cladding

A ceramic composite material, laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of insufficient bonding strength, difficult cost input, low mutual fusion, etc., to achieve high hardness and reduce residual stress. , the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

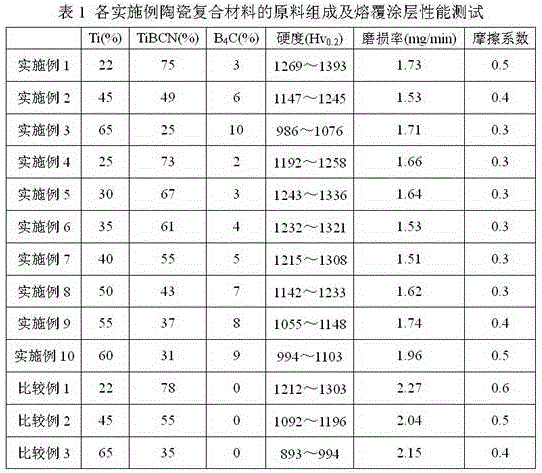

[0040] The raw materials used to prepare ceramic composite materials include Ti powder with a particle size of 100 mesh, TIBCN ceramic powder with a particle size of 150 mesh and B 4 C powder. Among them, TiBCN ceramic powder and B 4 C powder is dried before preparation to prevent the formation of pores in the cladding coating and bring defects to the cladding coating.

[0041] Weigh 220g of Ti powder, 750g of TiBCN ceramic powder, B 4 Add 30 g of C powder into a ball mill and mix for 2 hours to obtain a ceramic composite material for laser cladding on the titanium alloy surface.

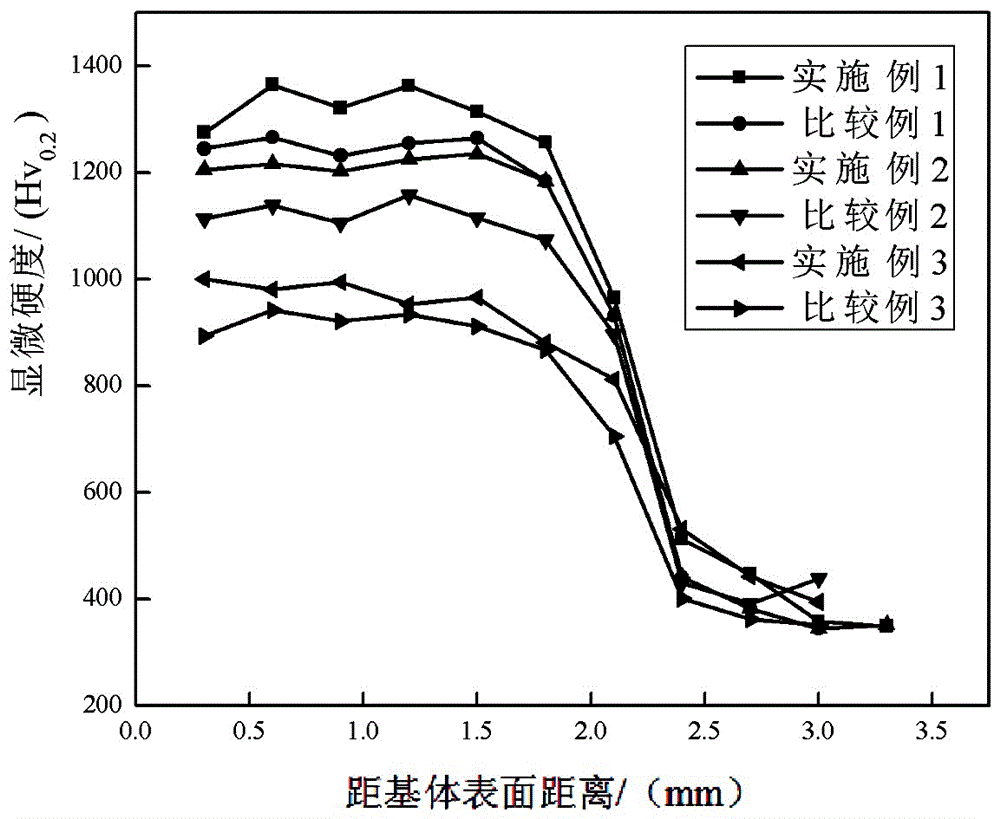

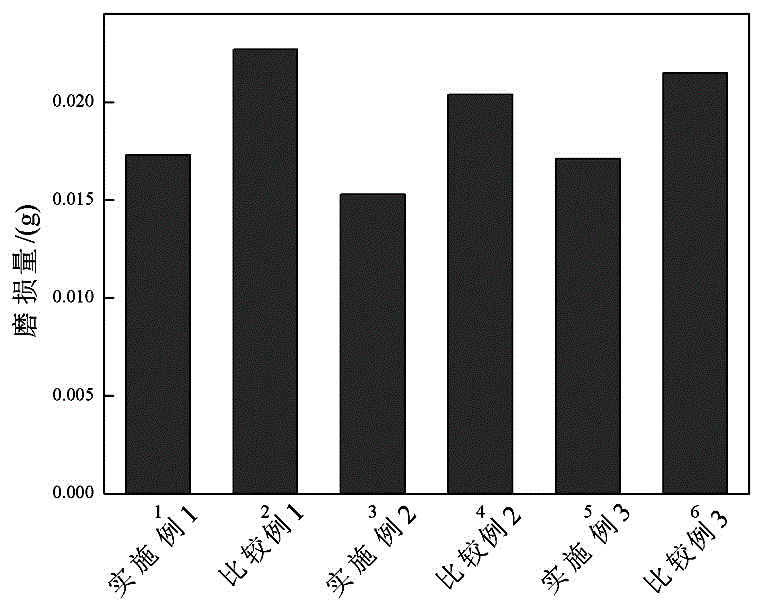

[0042] Using the ceramic composite material for laser cladding of the titanium alloy surface prepared above, laser cladding is performed on the surface of the titanium alloy sample that has been subjected to surface treatment. Specific laser cladding process parameters include: laser power 1500W, spot diameter 1.5mm, scanning speed 3mm / s, carrier pressure of ceramic composite material 0.6Mp, powd...

Embodiment 2

[0060] Weigh 450g of Ti powder with a particle size of 300 mesh, 490g of TiBCN ceramic powder with a particle size of 300 mesh, and B with a particle size of 500 mesh. 4 60g of powder C was prepared according to the method in Example 1 to obtain a ceramic composite material for laser cladding on the surface of a titanium alloy.

[0061] The laser cladding process parameters are: laser power 1000W, spot diameter 2mm, scanning speed 5mm / s, others are the same as in Example 1, and a TiBCN hard composite coating is formed on the surface of the titanium alloy according to the method in Example 1.

[0062] Test the performance of the cladding coating according to the test method of Example 1, and the cladding coating hardness is 1147~1245Hv 0.2 , the coating wear rate is 1.53mg / min, and the friction coefficient of the wear test is 0.4.

Embodiment 3

[0068] Weigh 650g of Ti powder with particle size of 150 mesh, 250g of TiBCN ceramic powder of 200 mesh, and B 4 100g of C powder was prepared according to the method in Example 1 to obtain a ceramic composite material for laser cladding on the titanium alloy surface.

[0069] The laser cladding process parameters are: laser power 1400W, spot diameter 3mm, scanning speed 5mm / s, others are the same as in Example 1, and a TiBCN hard composite coating is formed on the titanium alloy surface according to the method in Example 1.

[0070] Test the performance of the cladding coating according to the test method of Example 1, and the cladding coating hardness is 986~1076Hv 0.2 , the coating wear rate is 1.71mg / min, and the friction coefficient of the wear test is 0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com